Electric connector with enhanced clipping function

An electrical connector and performance technology, applied in the field of socket electrical connectors, can solve the problems of damage, easy short circuit, poor resistance and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to obtain a more specific understanding of the content of the present invention, one to several preferred embodiments are now illustrated, and detailed descriptions are as follows with reference to the drawings; in addition, in addition to the following detailed descriptions, the present invention can also be widely implemented in other embodiments middle.

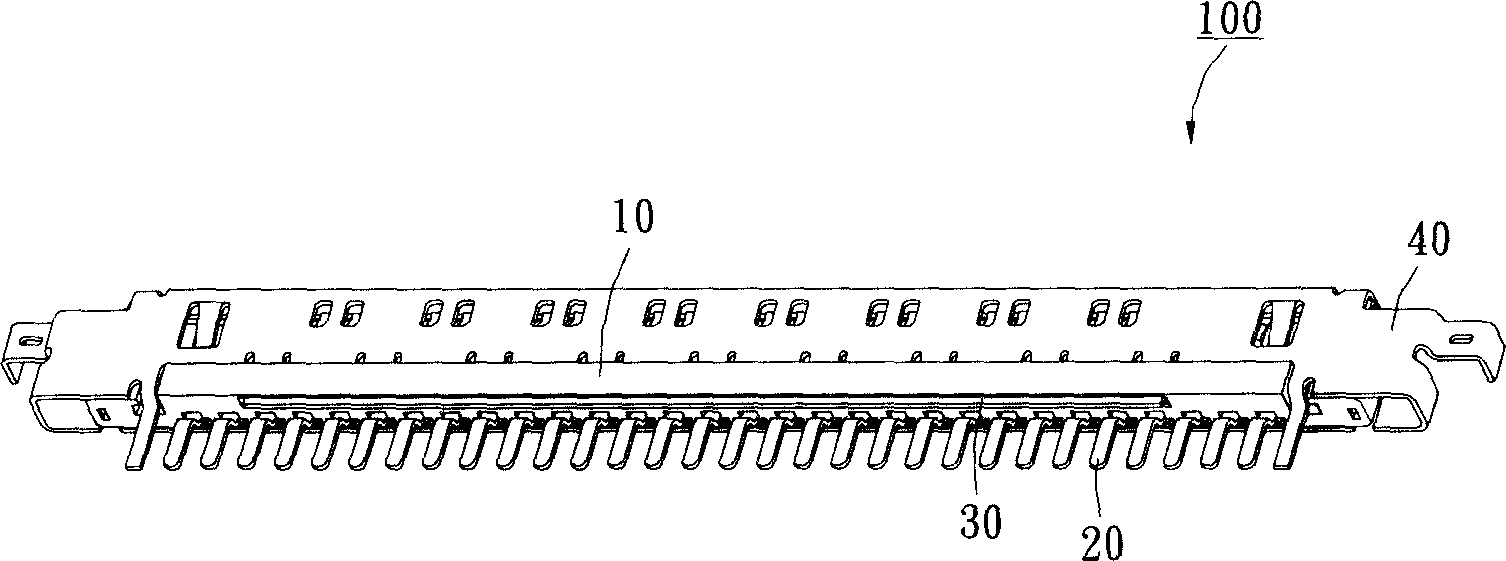

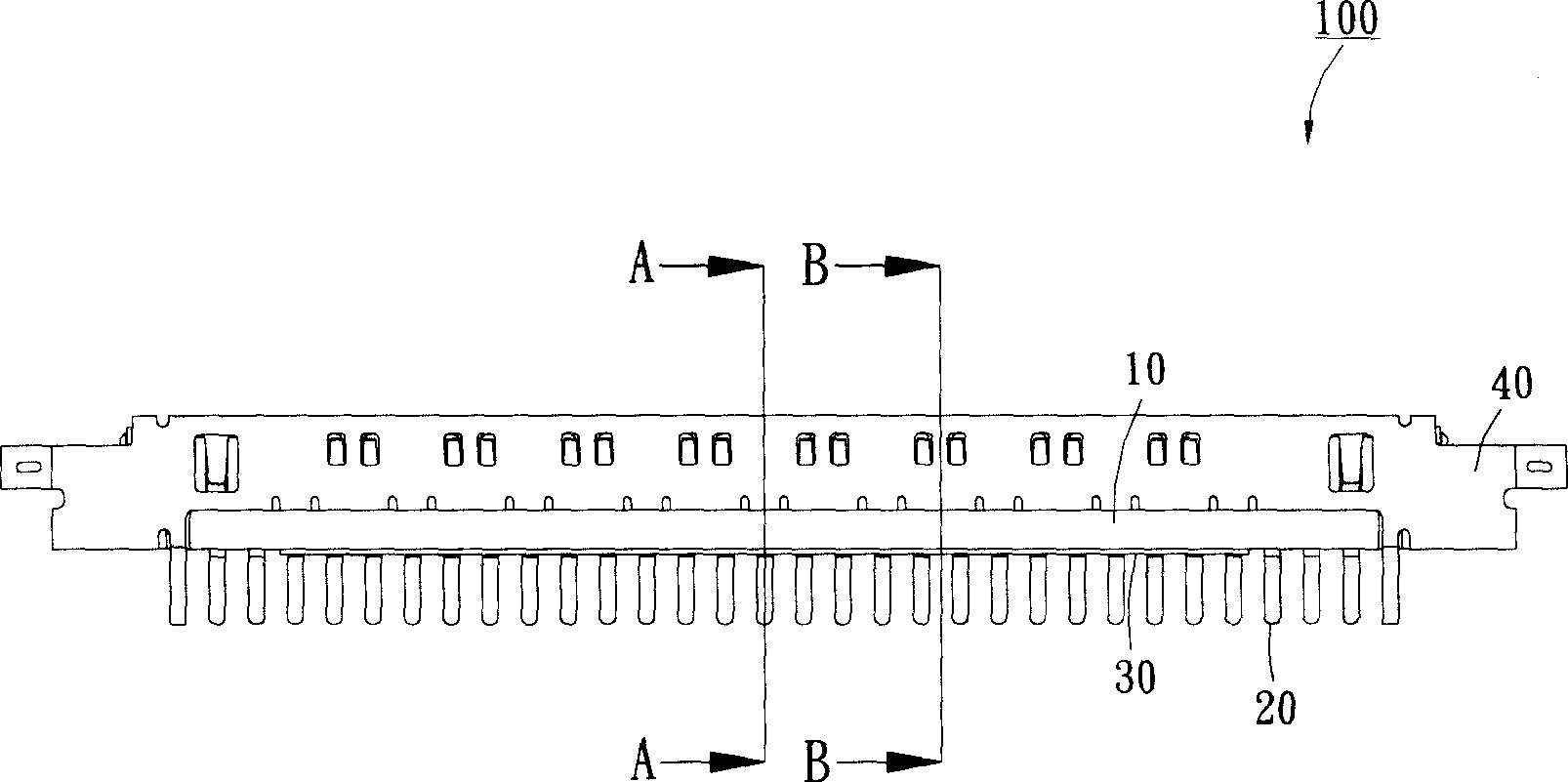

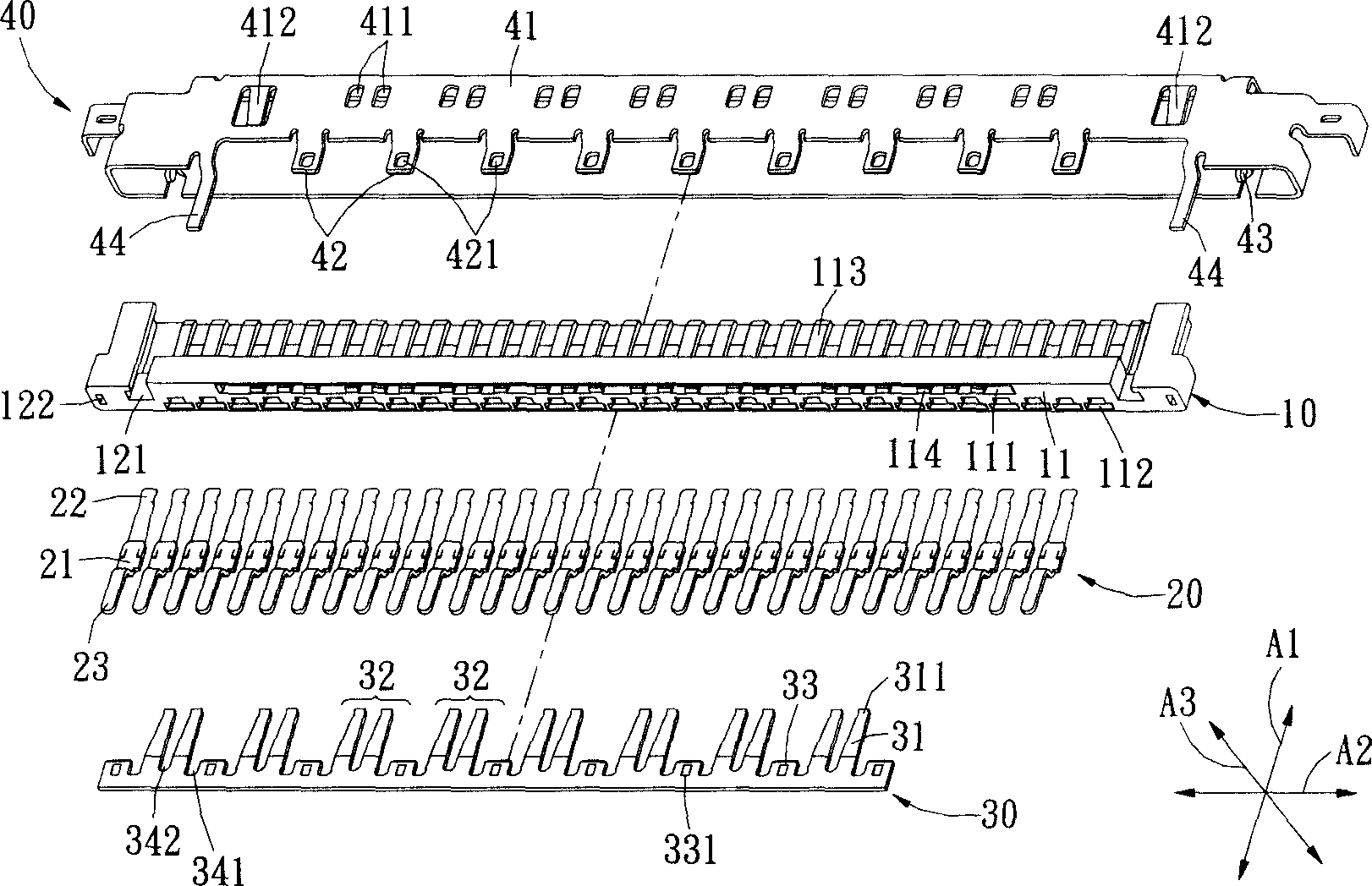

[0039] figure 1 , figure 2 , image 3 They are respectively a three-dimensional assembled view, a top view and an exploded view of components of a preferred embodiment of the present invention. The electrical connector 100 includes a main body seat 10, which is a slightly L-shaped frame formed by plastic. The rear side 11 of the main body seat is provided with an upper slot 111 and a plurality of terminal slots 112. The terminal slots 112 extend to the main body seat 10. On the inner surface 113 of the main body seat 10, grooves 121 and fitting holes 122 are provided on the left and right sides. A plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com