Vibration motor

A motor, a pair of technology, applied in the direction of electric components, casing/cover/support, control mechanical energy, etc., can solve the problem of conductive terminals prone to lateral shaking, etc., to ensure the contact margin, suppress vibration, and expand the lateral width. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

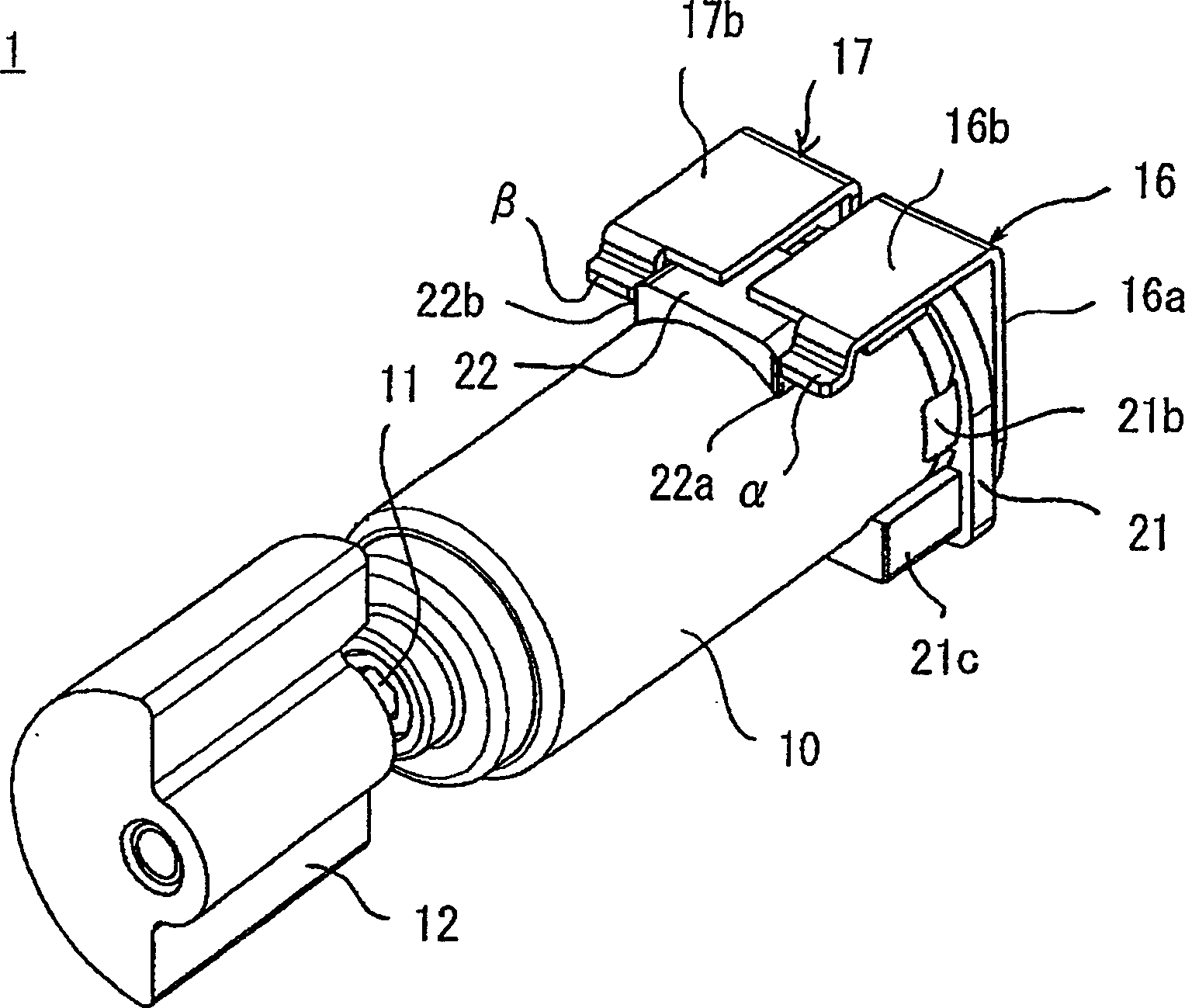

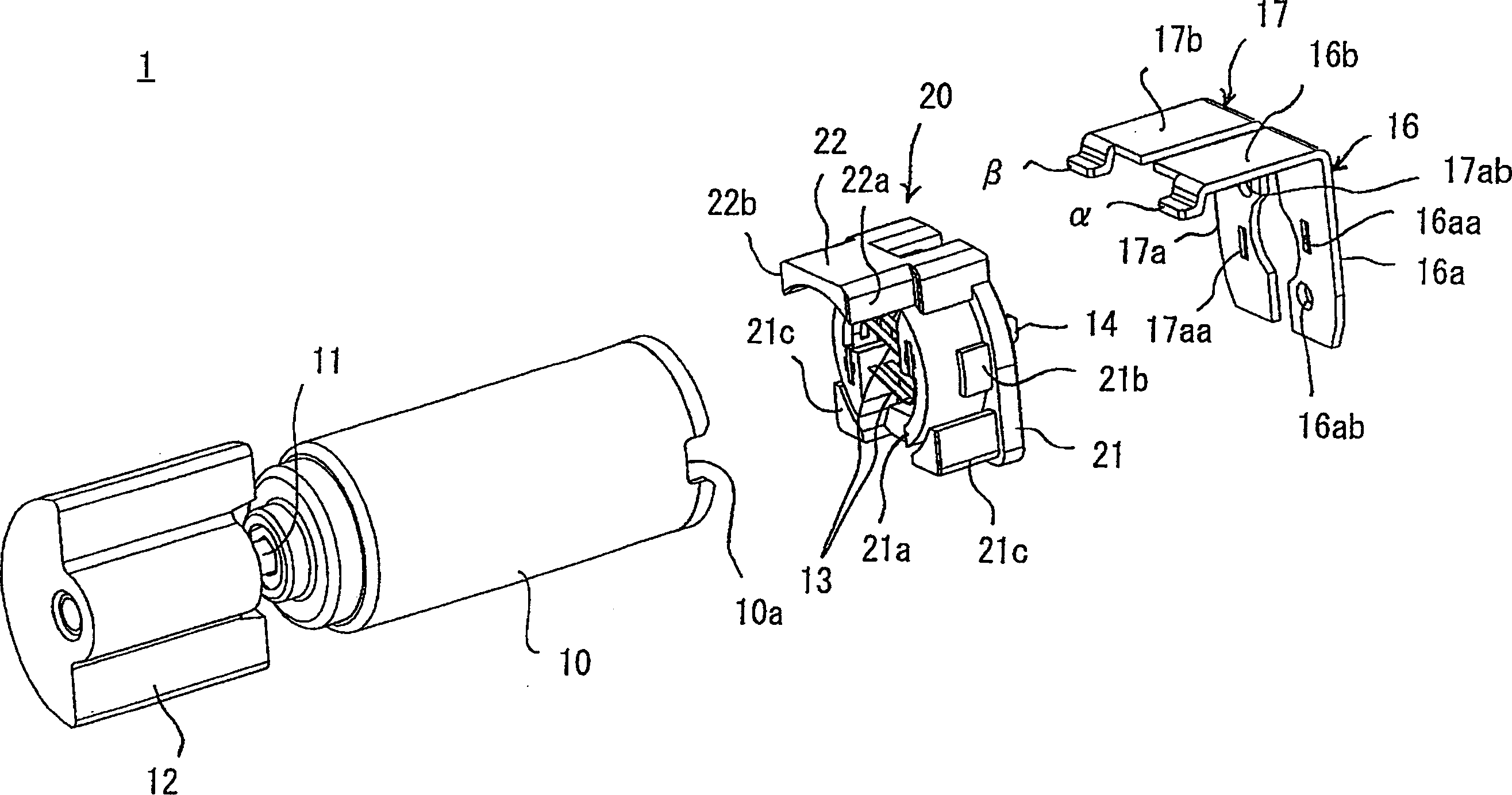

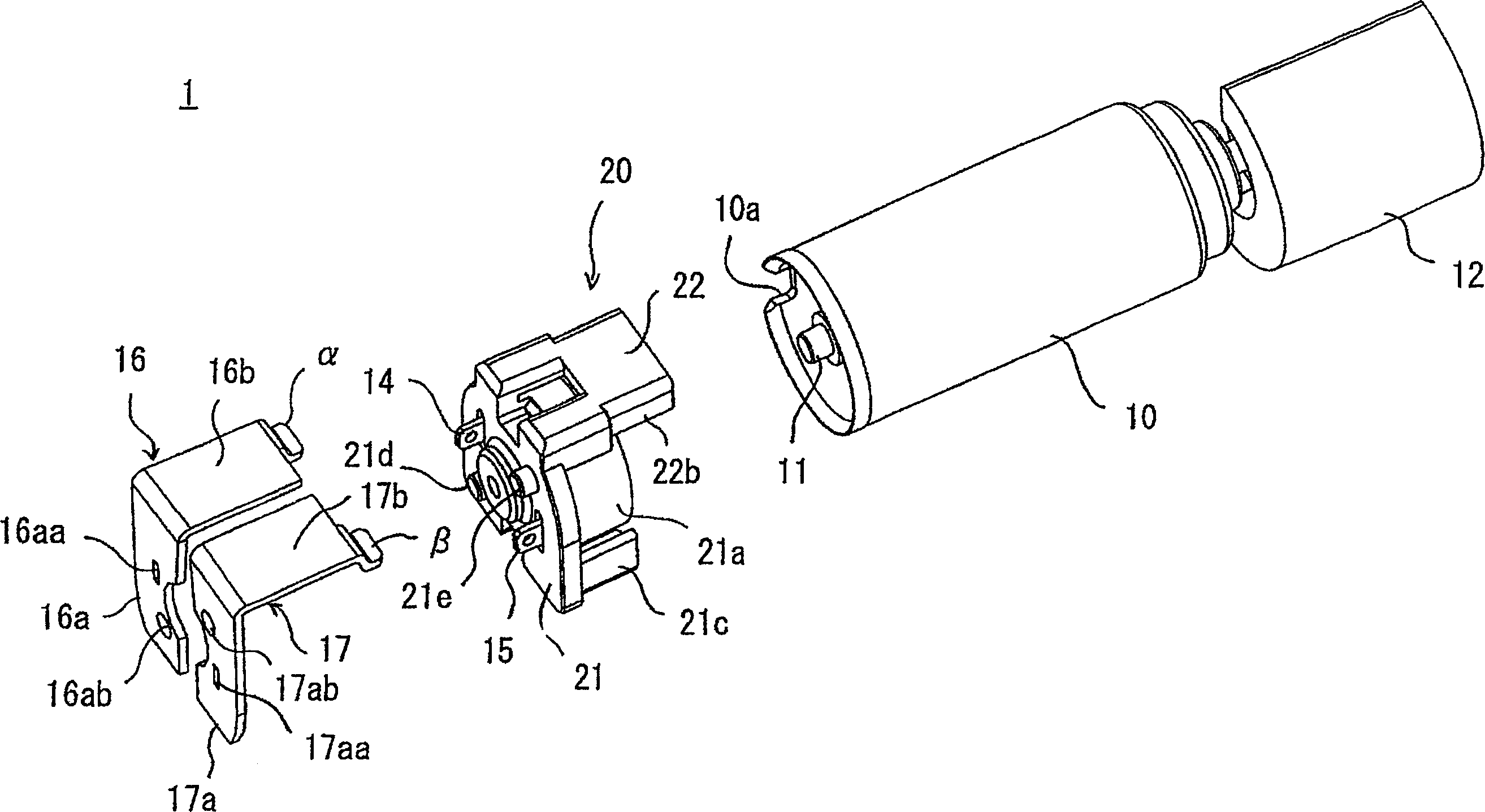

[0052] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0053] figure 1 It is an assembled perspective view showing the vibration motor related to one embodiment of the present invention. figure 2 It is an exploded perspective view partially disassembled of the above-mentioned vibration motor. image 3 from another angle figure 2 An exploded perspective view of the state shown. Figure 4 It is a perspective view showing a pair of plate-shaped conductive terminals used for the above vibration motor. Figure 5 It is a side view which shows the state which assembled the said vibration motor to a board|substrate.

[0054] The vibration motor 1 in this embodiment is configured by attaching an eccentric weight 12 to a motor shaft 11 projecting from a cylindrical motor case 10 . In the motor housing 10, a magnet (not shown) fixed on its inner peripheral surface, a rotor (not shown) fixed on the motor shaft 11, and a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com