Draft apparatus in spinning machine and control method of the same

The technology of a drafting device and a control method, which is applied in the field of drafting devices, can solve problems such as the inability to prevent uneven filaments and the inability to fully suppress the twisting of apron rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

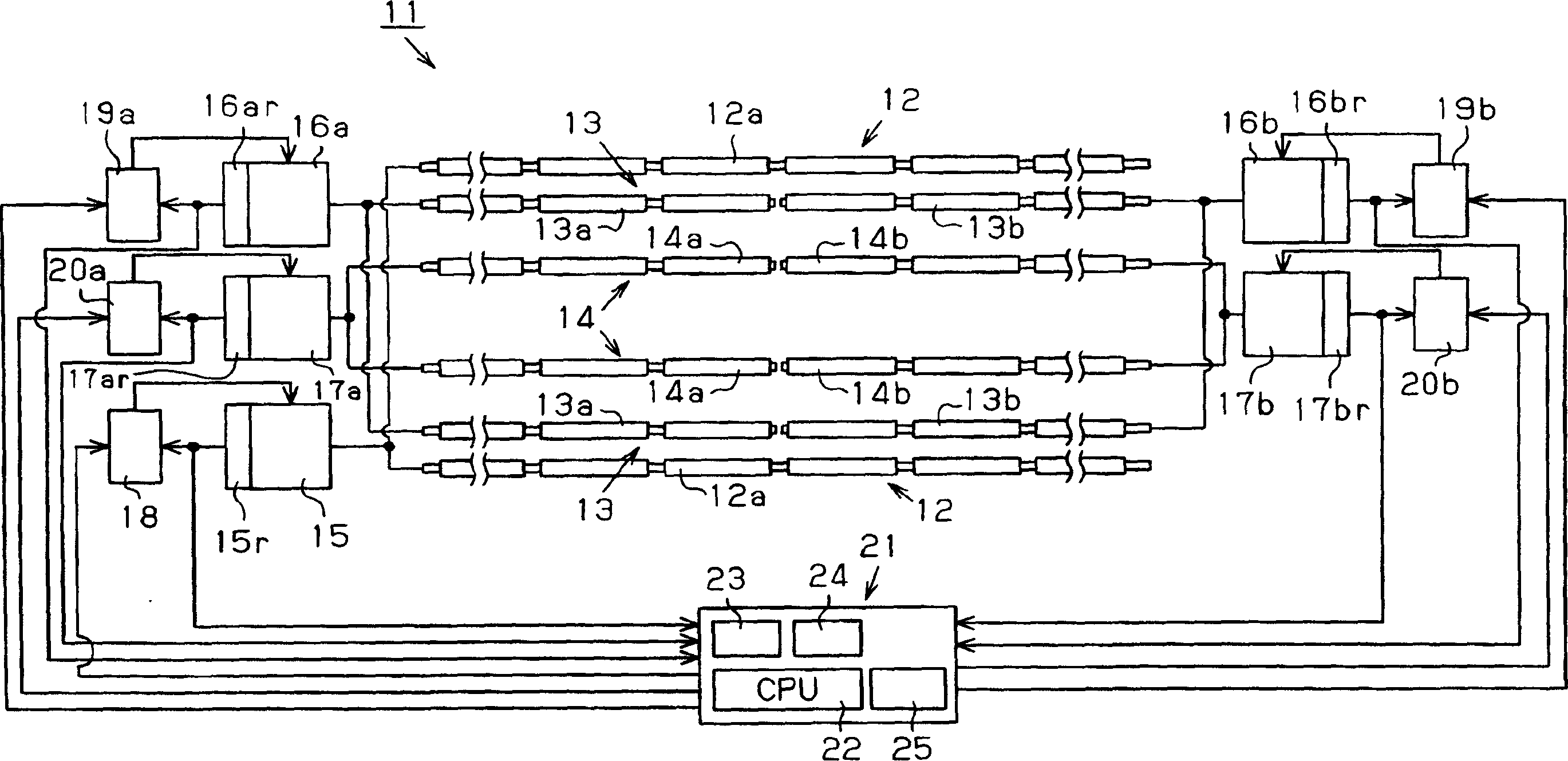

[0020] Below, according to figure 1 as well as figure 2 An embodiment in which the present invention is embodied will be described. figure 1 A drawing device 11 extending in the longitudinal direction of the machine of the ring spinning frame is shown.

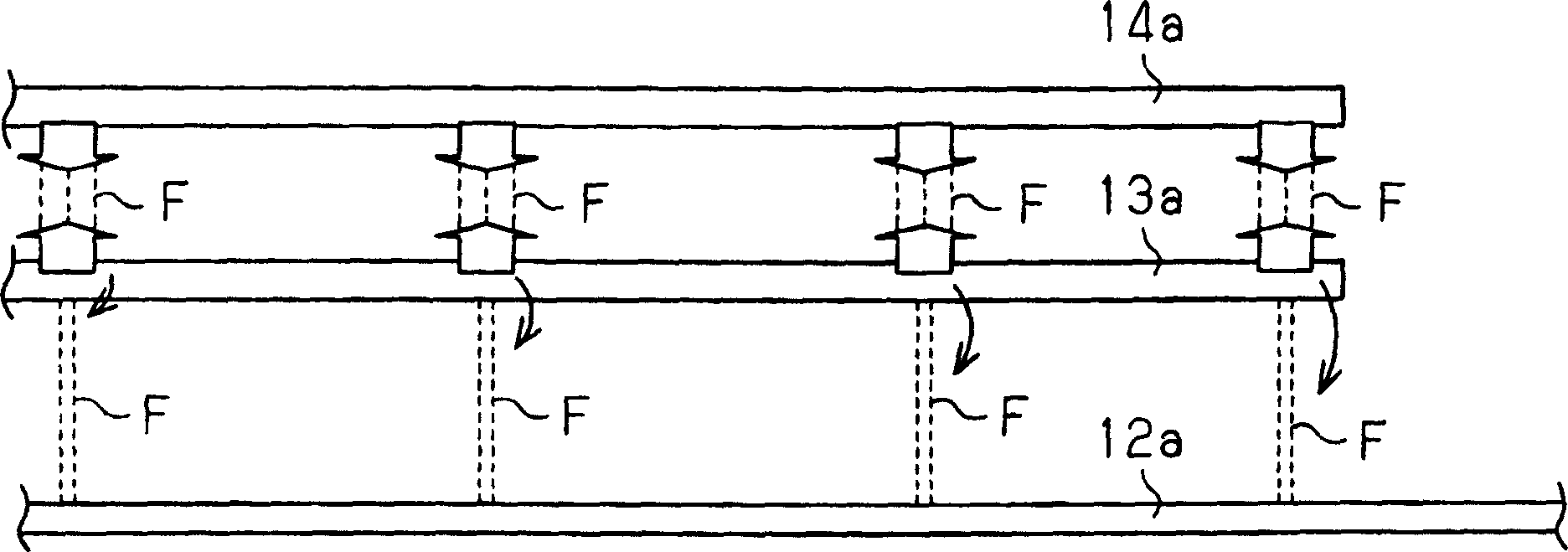

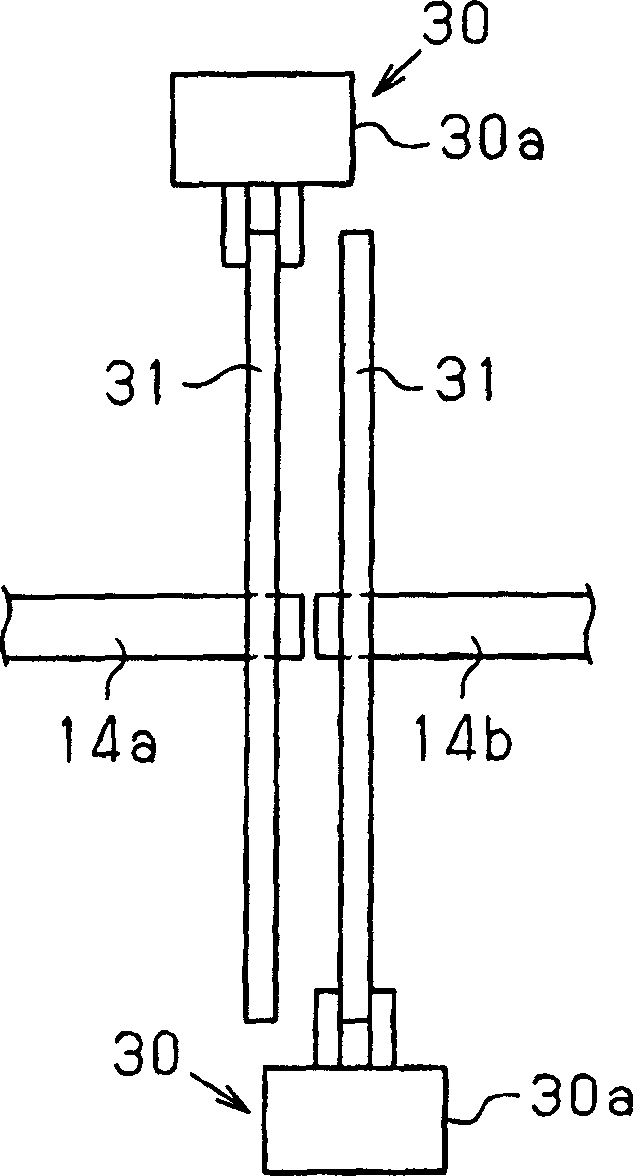

[0021] Such as figure 1 As shown, the 3-line drafting device 11 has a pair of front bottom rollers 12 extending in the longitudinal direction of the machine, a pair of middle bottom rollers 13 disposed on the inner side, and a pair of rear bottom rollers 14 disposed on the inner side. . The front bottom roller 12 is supported at a predetermined position of an unillustrated roller seat. The middle bottom roller 13 and the rear bottom roller 14 are supported by a bracket (not shown) whose position can be adjusted in the direction of clutching with respect to the front bottom roller 12 . The middle bottom roller 13 has an apron (not shown). Moreover, corresponding to each bottom roller 12-14, a front bottom roller, a middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com