Coating device

A coating device and coating technology, applied in the direction of the surface coating liquid device, display device, spraying device, etc., can solve the problems of nozzle 202 skew, interval deviation, uneven coating, etc., to prevent deviation and suppress Effect of uneven coating and preventing skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

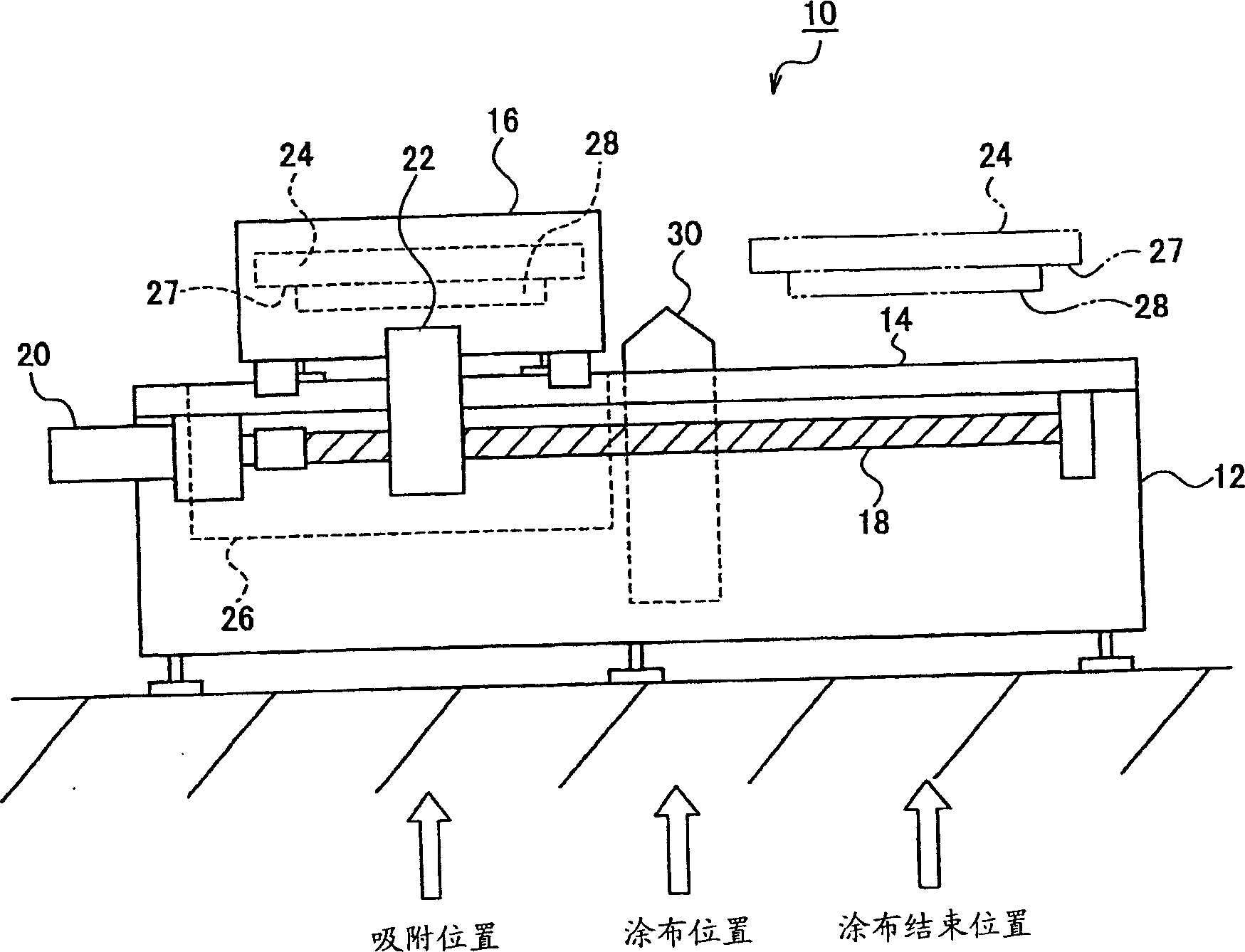

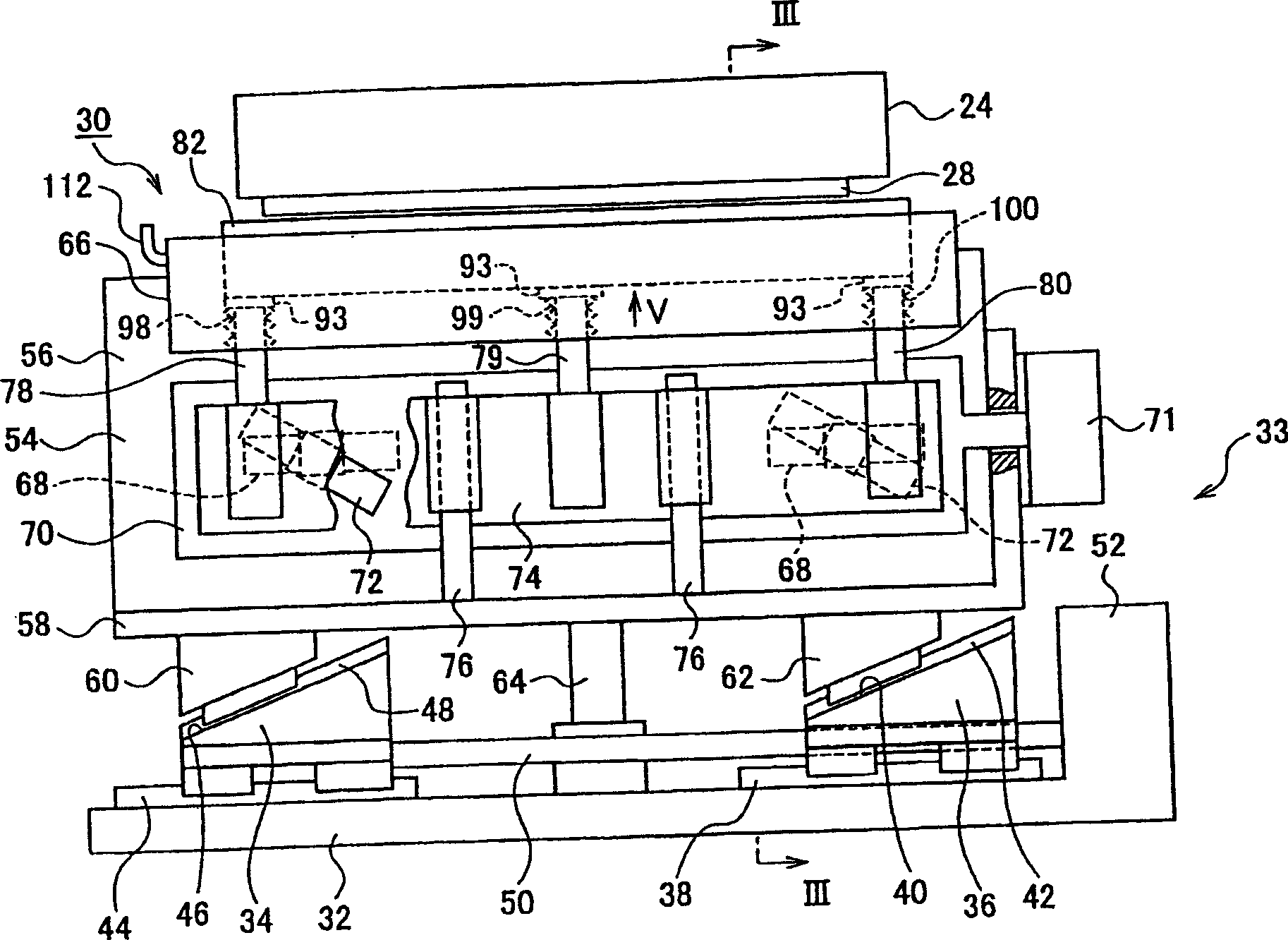

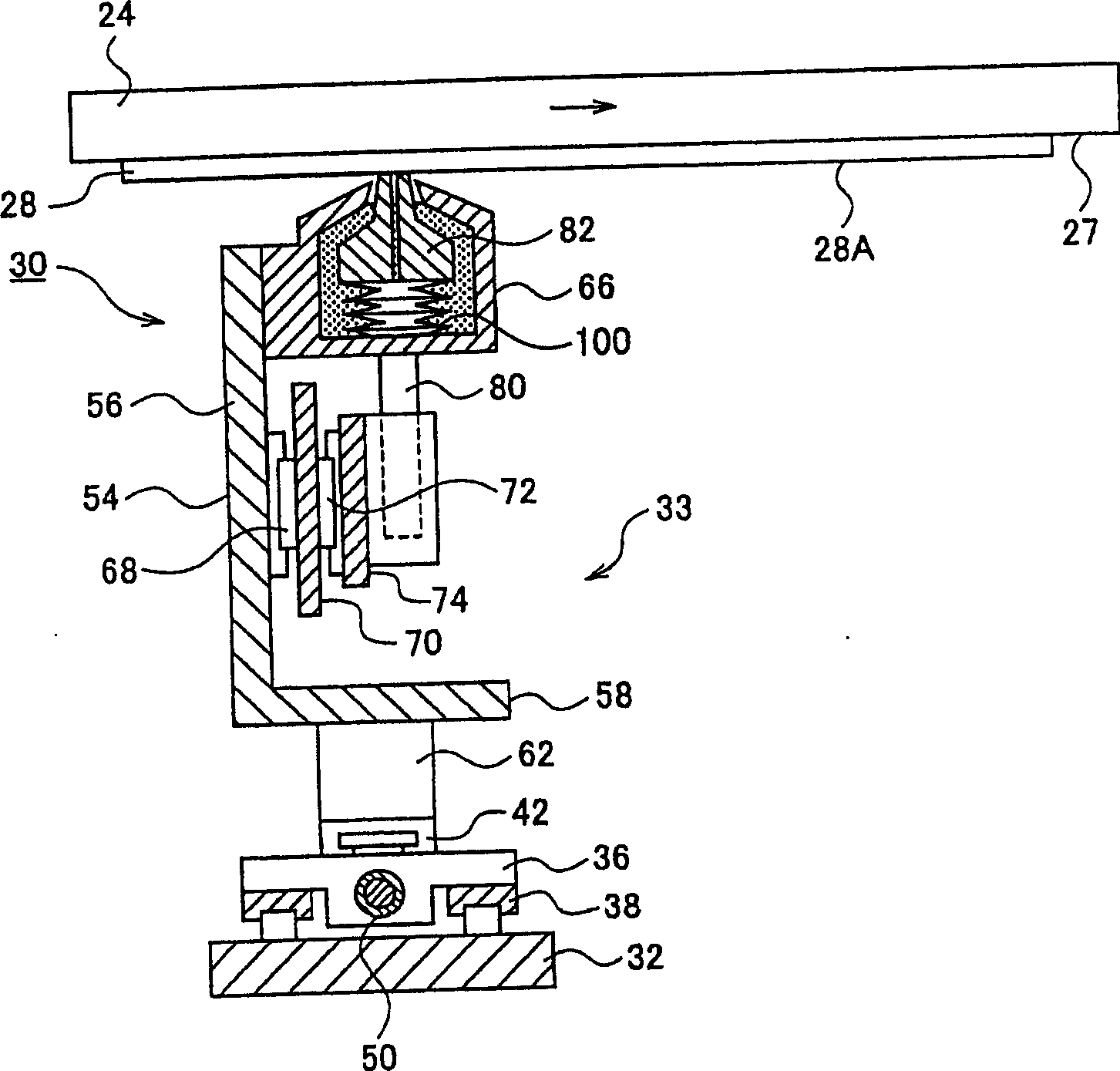

[0031] figure 1 It is a schematic side view showing one embodiment of the coating apparatus of the present invention. figure 2 yes means figure 1 Front view of the coating system. image 3 is along figure 2 Sectional view of line III-III.

[0032] Such as figure 1 As shown, the coating device 10 is composed of: a base frame 12; a coating system 30 arranged on the base frame 12; a moving frame 16, which is supported on the base frame 12 and can move horizontally; a suction table (hereinafter referred to as stage) 24, which is installed on the moving frame 16, and adsorbs the substrate 28; and a holding system 26, which holds the substrate 28 in a detachable manner.

[0033] The substrate 28 is a photomask in which a light-shielding film is formed on a transparent substrate. The coating liquid applied to the substrate 28 is a resist, and forms a ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com