Main transmission device of rolling machine

A main drive and plate rolling machine technology, applied in the field of plate rolling machines, can solve the problems of large universal couplings, difficult processing, and high price, and achieve the effects of ensuring production safety, avoiding easy damage, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

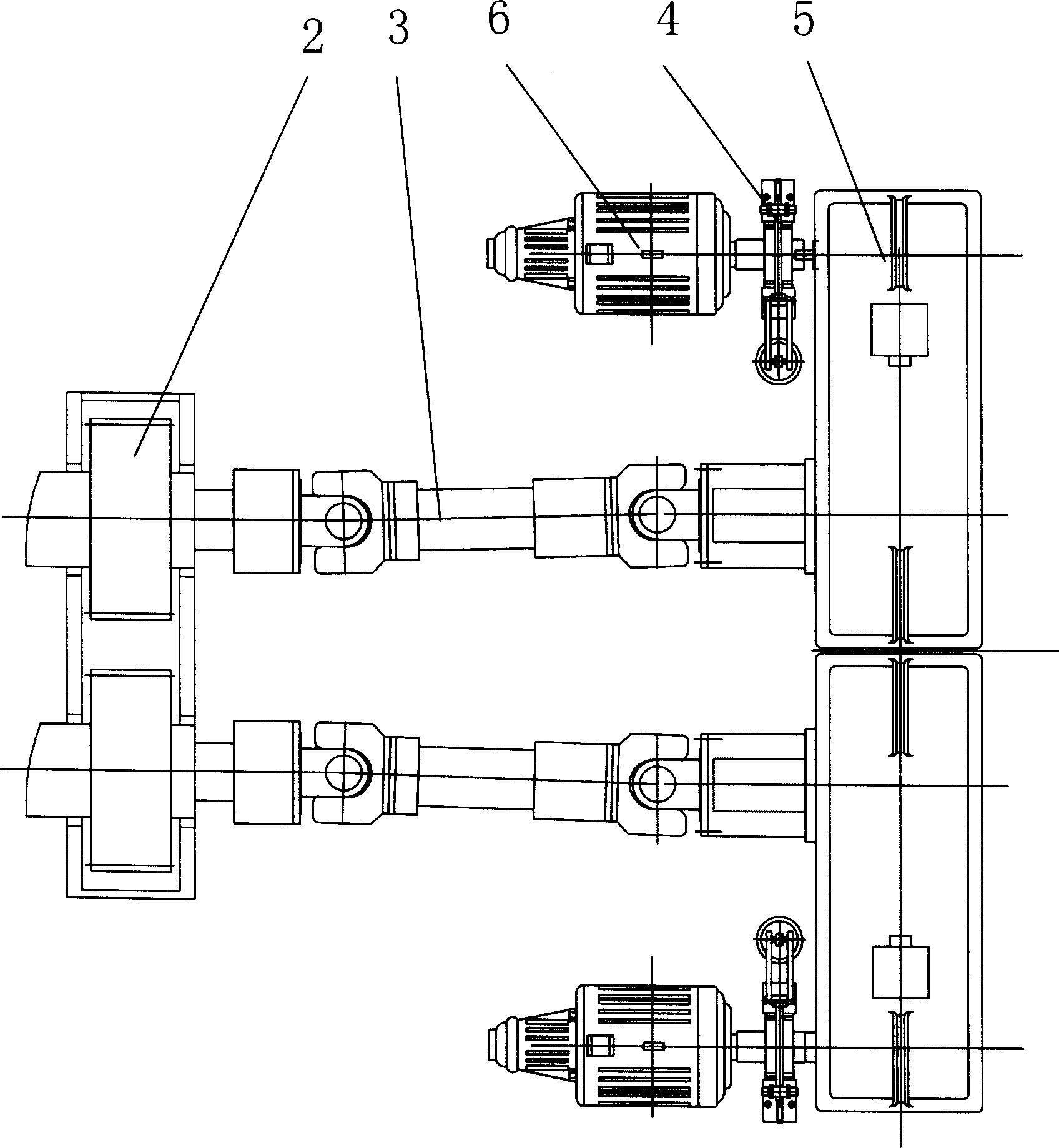

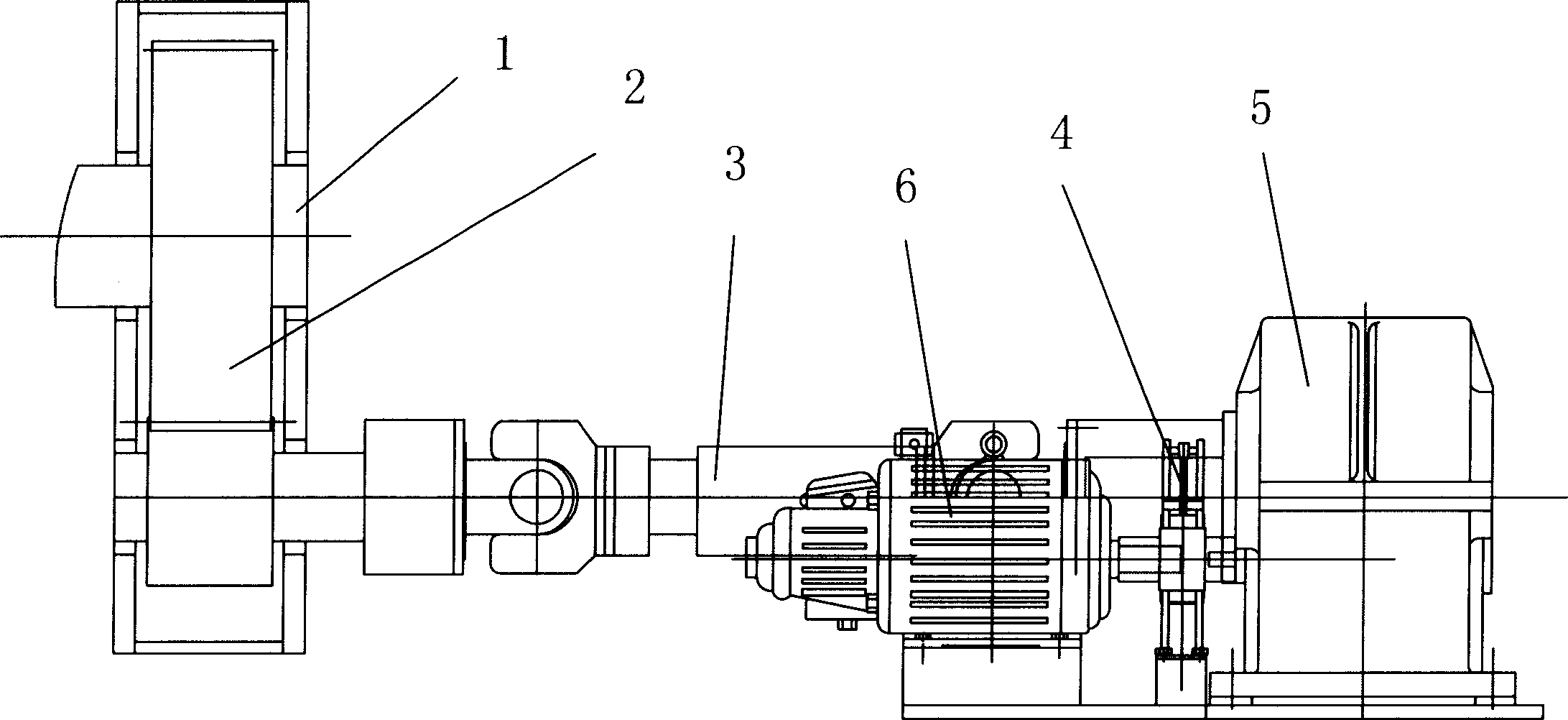

[0009] The present invention is further described below in conjunction with embodiment. Such as figure 1 with figure 2 As shown, the present invention discloses a main transmission device of a plate rolling machine, including a lower roll 1, a reduction device 2, a universal coupling 3, a brake 4, a reducer 5, and a motor 6. The lower roll 1 shaft The end is equipped with a one-stage or multi-stage deceleration device 2, and then connected to the decelerator 5 connected to the motor 6. In this way, the universal coupling is not needed, which can greatly reduce the cost, and also avoid the problem that the coupling is easily damaged. Ensure production safety.

[0010] A universal coupling 3 can be installed between the speed reducer 2 mounted on the shaft end of the lower roller and the speed reducer 5 connected to the motor 6, or it can be installed directly between the speed reducer mounted on the shaft end of the lower roller and the motor. Universal coupling is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com