Substrate carrier

A technology for substrate conveying and conveying devices, which is applied in the direction of photolithographic process exposure devices, conveyor objects, transportation and packaging, etc., can solve the problems of limiting the operating range of other conveying arms, reducing the degree of freedom of conveying arm operation, and complicated control, etc., to achieve Improvement of conveying efficiency, simplification of operation control, and increase of operational freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

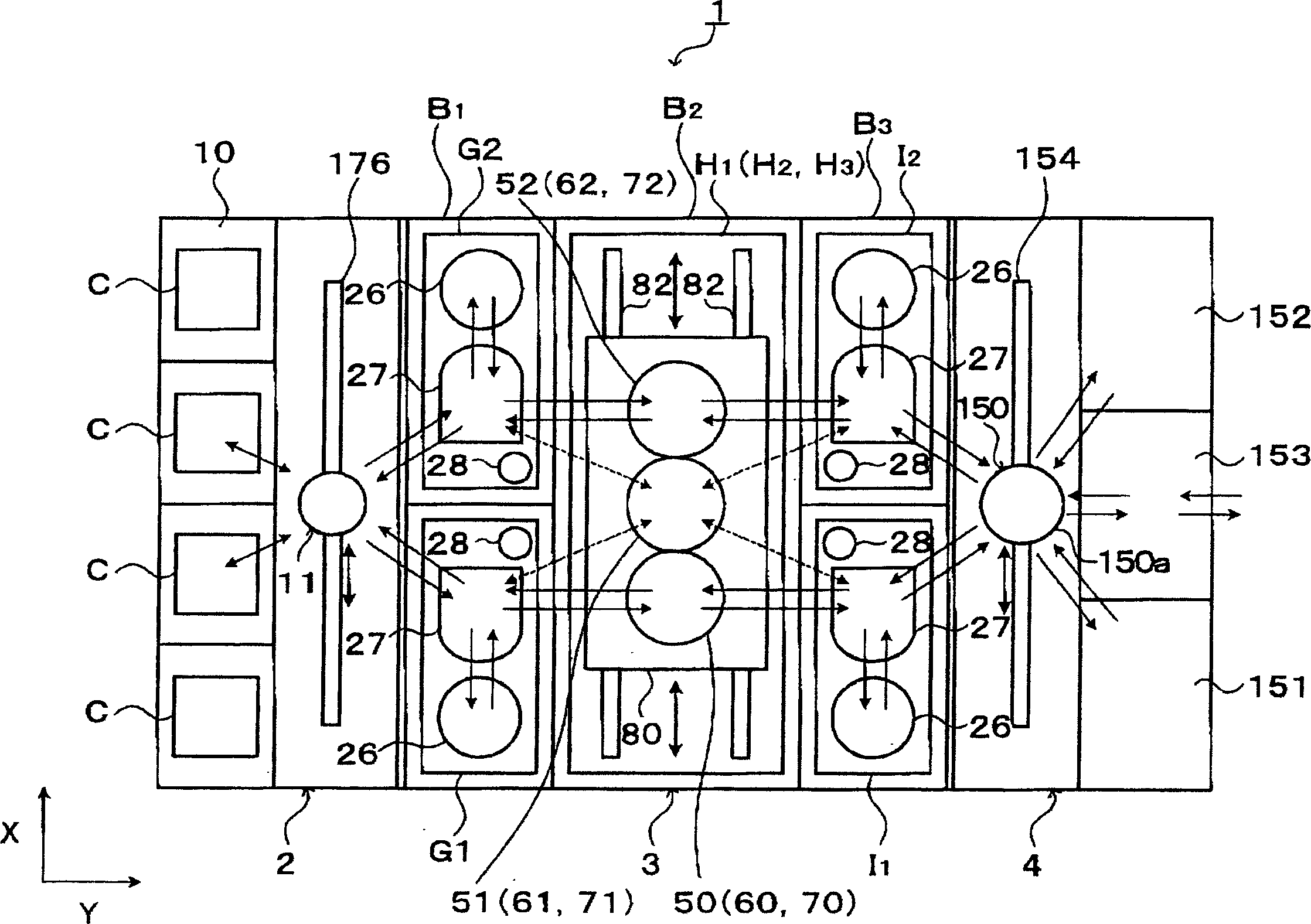

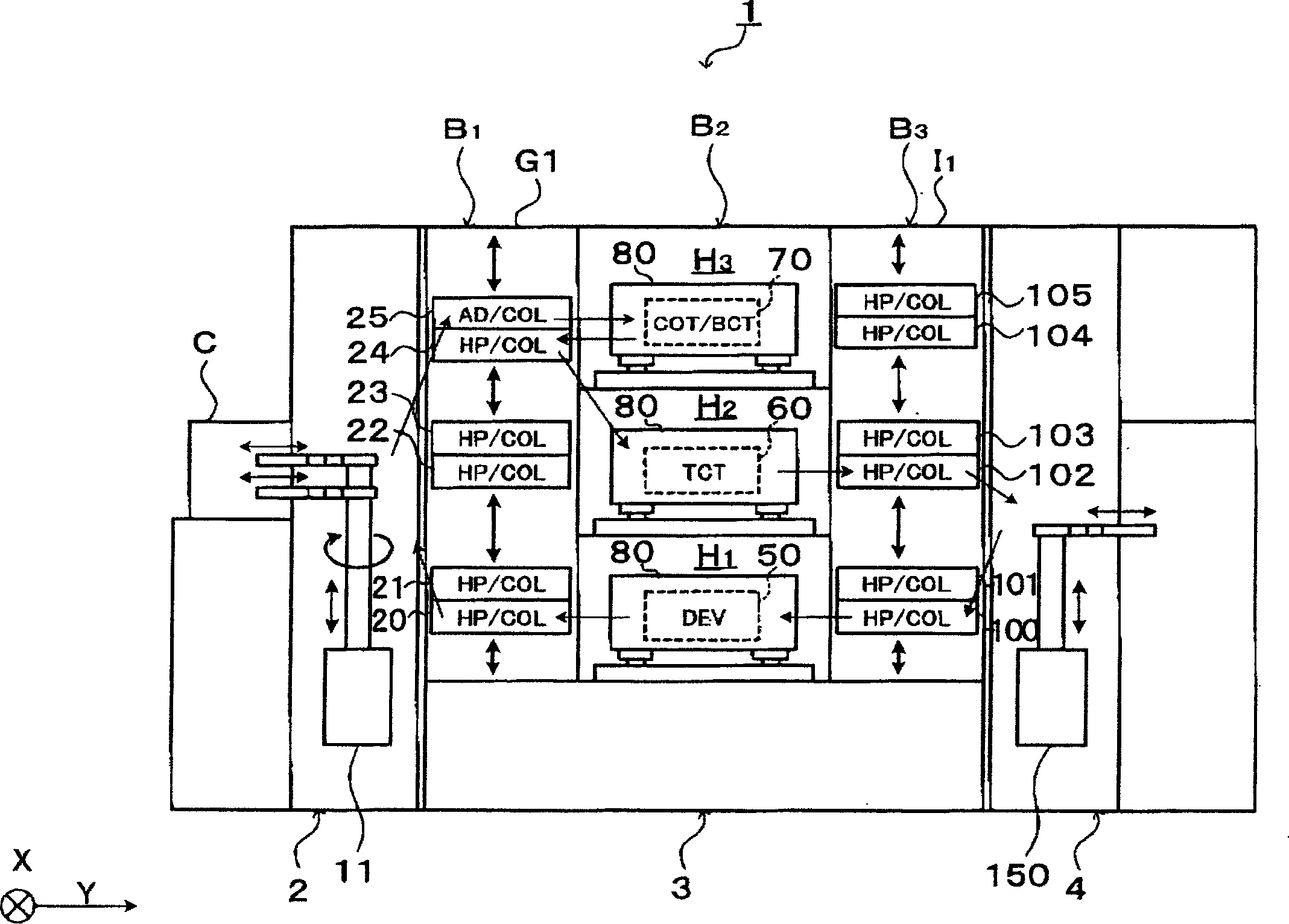

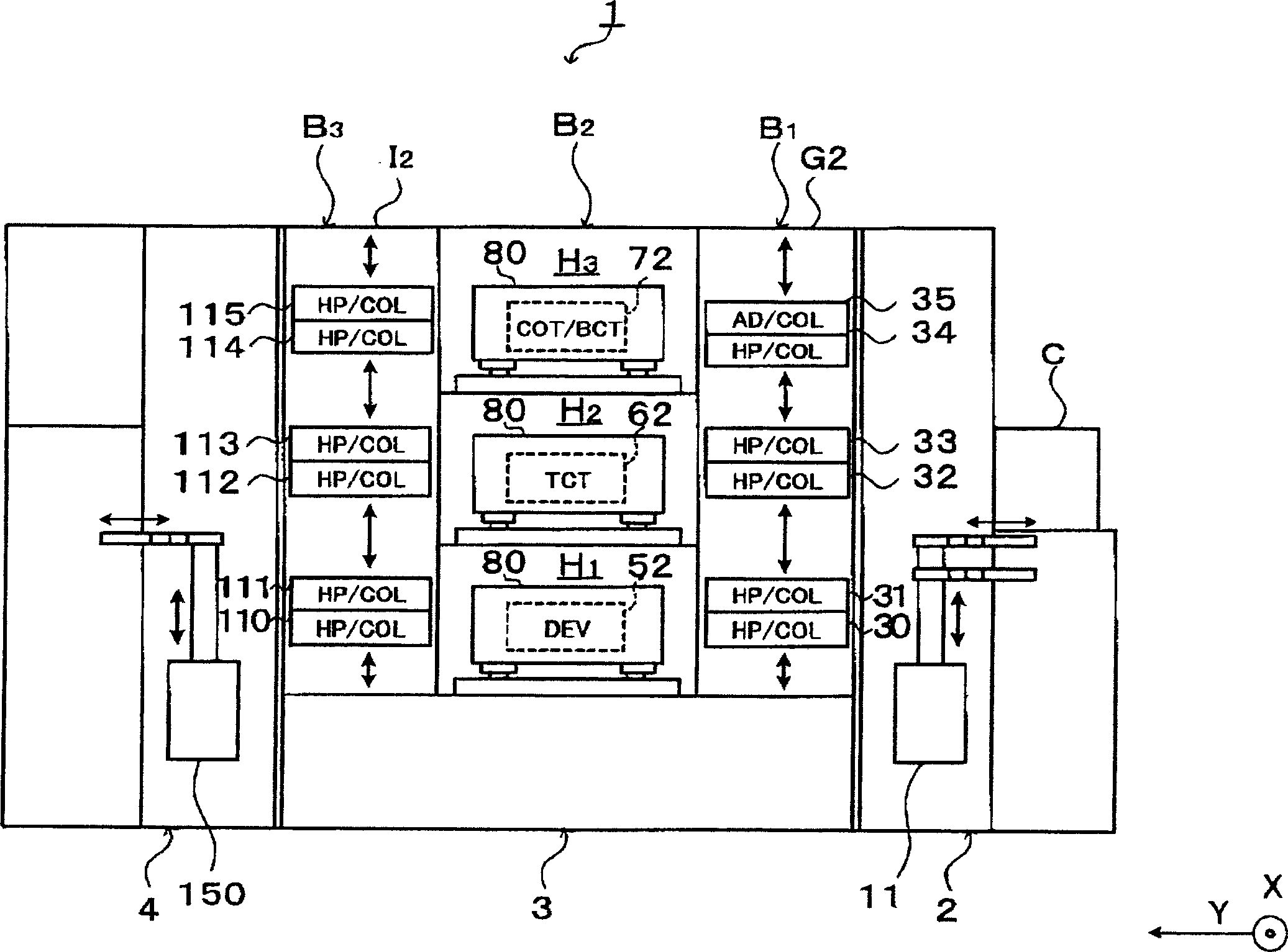

[0028] Next, the best mode for carrying out the present invention will be described. figure 1 It is a plan view showing a schematic configuration of a substrate processing system 1 equipped with a substrate transfer device according to the present embodiment.

[0029] The substrate processing system 1 includes a configuration in which a cassette station 2 such as figure 1 As shown, it loads and unloads, for example, 25 wafers W from the outside to the substrate processing system 1 in units of cassettes, and loads and unloads wafers W from the cassette C; A plurality of units that perform various processes in the photolithography process; and an interface unit 4 that is provided adjacent to the process station 3 and that transfers the wafer W to and from an exposure device (not shown). The box station 2, the processing station 3 and the interface part 4 face the Y direction ( figure 1 The left and right directions) are connected in series.

[0030] On the box station 2, a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com