Method for direct bonding of orthodontic brackets

A bracket and direct technology, applied in brackets, medical science, dentistry, etc., can solve the problems of cumbersome indirect bonding and high technical requirements, and achieve the effect of easy popularization, reduced complexity, and reduced professional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

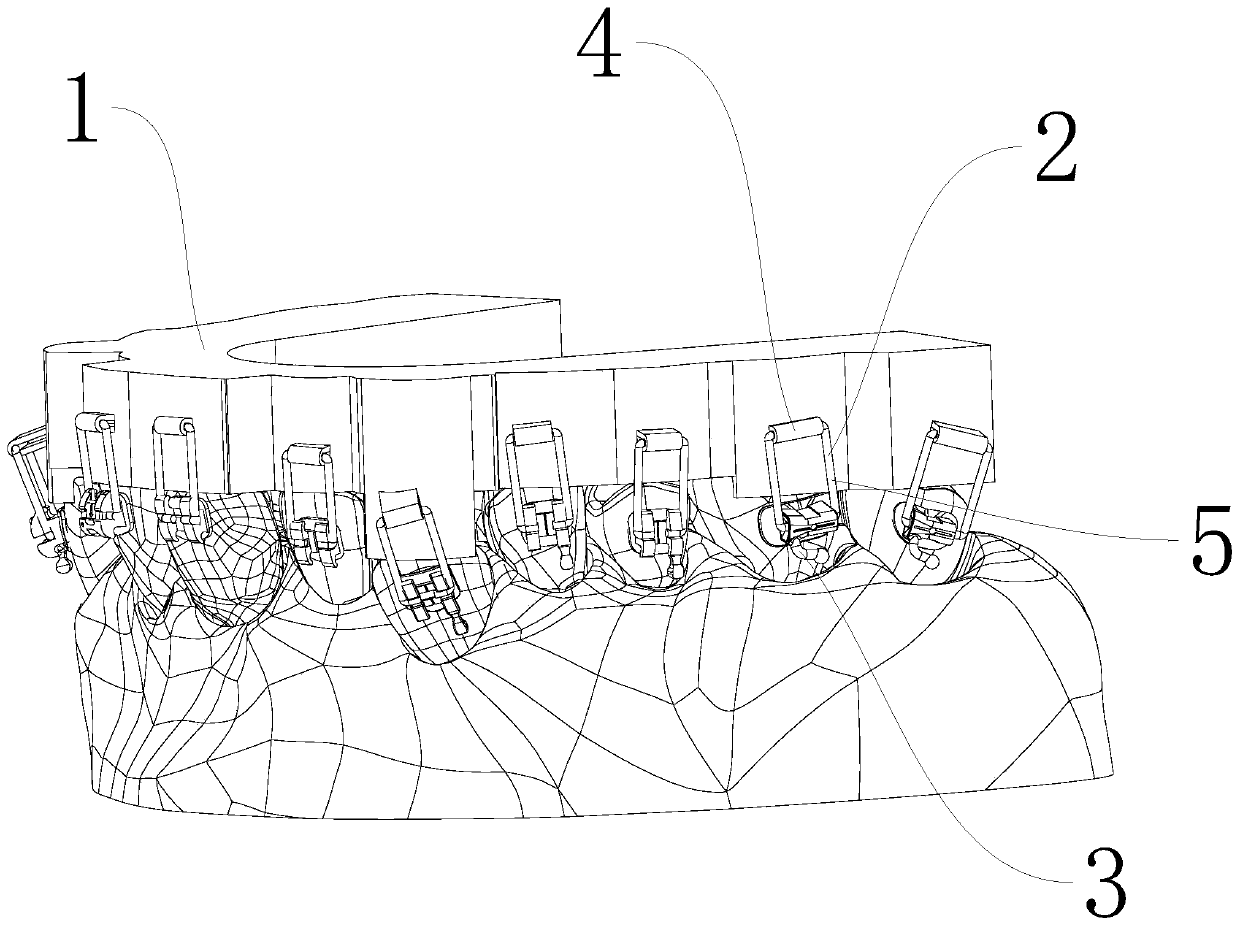

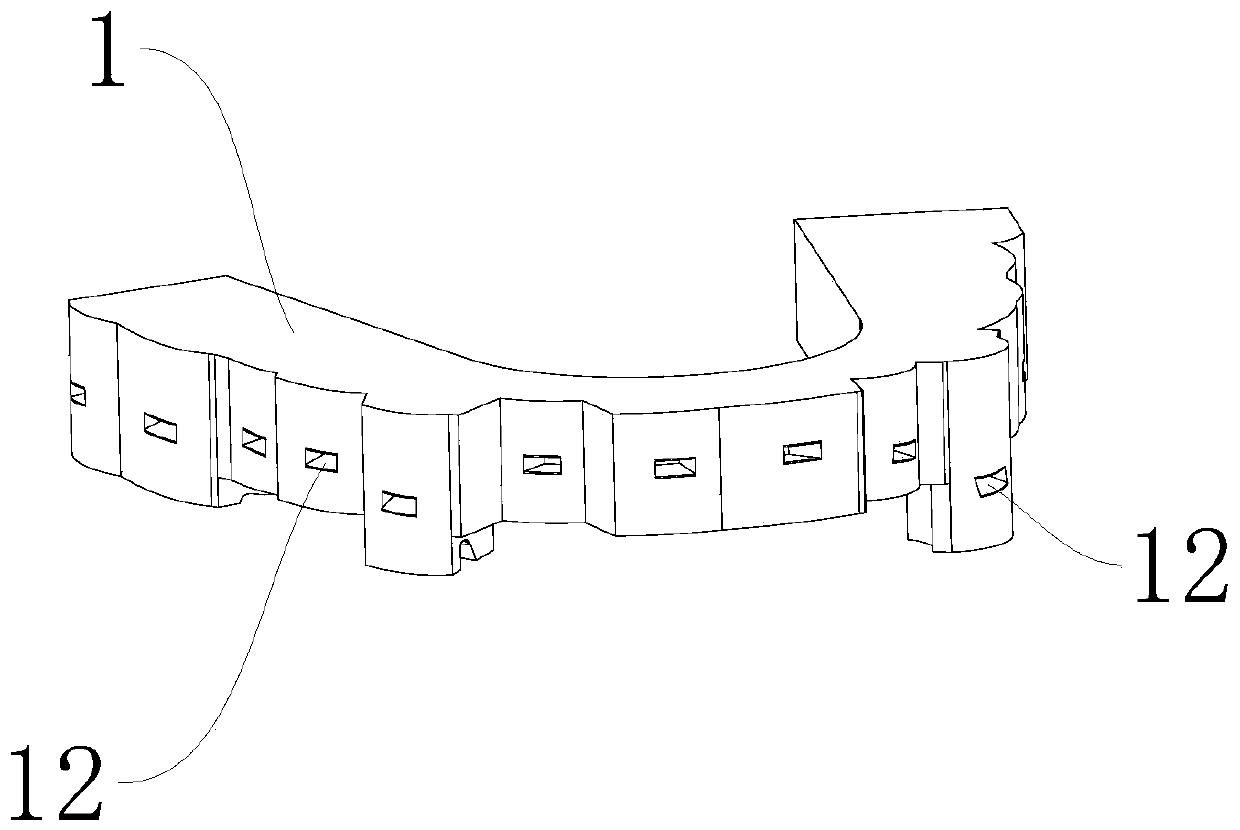

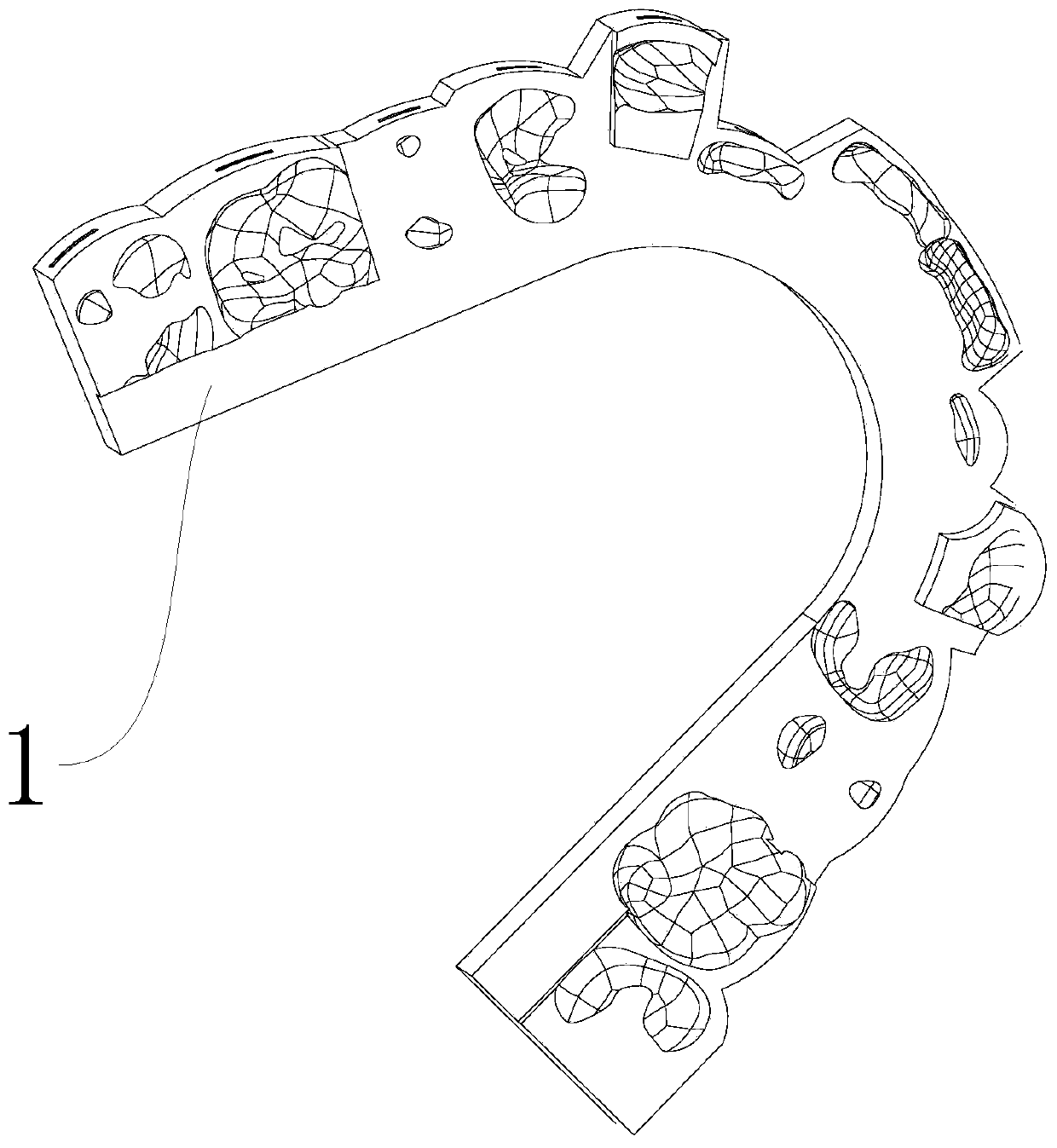

[0069] Such as figure 1 indivual figure 2 As shown, a method for direct bonding of brackets includes a tray 1 and a mounting frame 2, each mounting frame 2 is used to install a bracket 3, and the mounting frame 2 includes a bracket 4 and a positioning clip 5,

[0070] Tray 1, used as a support base for installing the mounting frame 2,

[0071] The bracket 4 is used as a fixed support, one end of which is connected and fixed to the lingual or labial side of the tray 1;

[0072] The positioning clip 5, as a rotating part, is used to connect with the bracket 3 to adjust the position of the bracket 3;

[0073] The positioning clip 5 includes a damping shaft 6, which cooperates with the bracket 4, and the positioning clip 5 rotates around the bracket 4 through the damping shaft 6, and the bracket 4 and the tray 1 are integrally formed or detachable. The origin of the definition of the damping shaft 6 is that during the installation of the bracket 3 , when the damping shaft 6 ro...

Embodiment 2

[0103] A method for direct bonding of brackets, this embodiment includes the technical solution in Example 1, and also includes the following supplementary technical solution: the distance between the inner walls of the assembly space 10 connecting the parts of the installation groove 7 is smaller than the inner diameter of the installation groove 7 Dimensions, the assembly space 10 of the part connecting the installation groove 7 is the part of the installation groove 7 away from the end of the connecting part 11 . This structural design can ensure that the damping shaft 6 enters the installation slot 7 against a certain resistance during installation to the installation slot 7 , and prevents the damping shaft 6 from slipping in the installation slot 7 . In this embodiment, the specific implementation method of this structure is to set up arc-shaped grooves on the adjacent sides of the first splint 8 and the second splint 9, so that the distance between the two arc-shaped groo...

Embodiment 3

[0105] A method for direct bonding of brackets. This embodiment includes the technical solution in Example 2, and also includes the following supplementary technical solution: the end of the installation groove 7 near the connecting portion 11 is connected with a deformation groove 18 . The function of the deformation groove 18 is that when the installation groove 7 is deformed by force, the deformation force can be transferred to the deformation groove 18 to facilitate the deformation of the installation groove 7, and at the same time, it can avoid excessive friction between the installation groove 7 and the damping shaft 6 As a result, stagnation occurs between the installation groove 7 and the damping shaft 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com