Novel technique of producing laser paper

A production process and new process technology, applied in the new process field of making laser paper with layered effect, can solve the problems of single transfer effect, waste of raw materials, unenvironmental materials, etc. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A new process for making laser paper, comprising the following steps:

[0030] A. Plate making

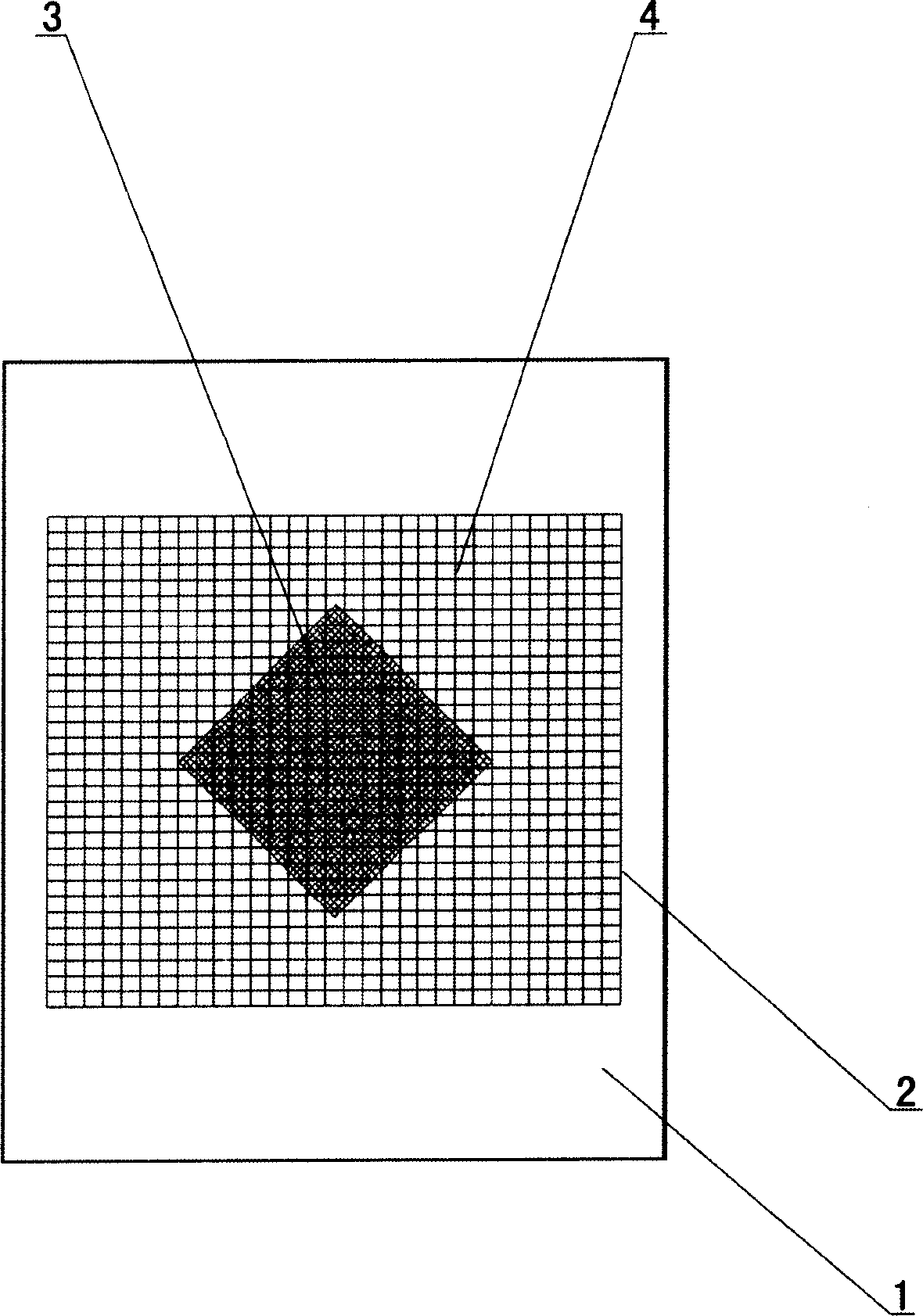

[0031] As shown in the drawings, according to the production process of the screen printing plate 1, when designing the pattern 2 of the screen printing 1, the screen printing method is used to make the screen printing plate 1 have a certain percentage of dots, so that the printing plate has a high Proportional dot percentage part 3 and low ratio dot percentage part 4, that is, adding a high proportion of dot percentage to the part that needs to be highlighted on the printing plate (for example, text or image) to form a part with a high proportion of dot percentage 3. The remaining part is added with a low percentage of dots to form a part 4 with a low percentage of dots, so that the screen printing plate has a certain level of tone;

[0032] B. Glue

[0033] The transfer glue is printed on the paper through the above screen printing plate 1, that is, the transfer glue is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com