Tire wheel assembly

一种组装体、车轮的技术,应用在车轮、充气轮胎、辐板式车轮等方向,能够解决隔板大小限制、变形、难以提高空腔共鸣音降低效果等问题,达到提高降低效果、分裂显著的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

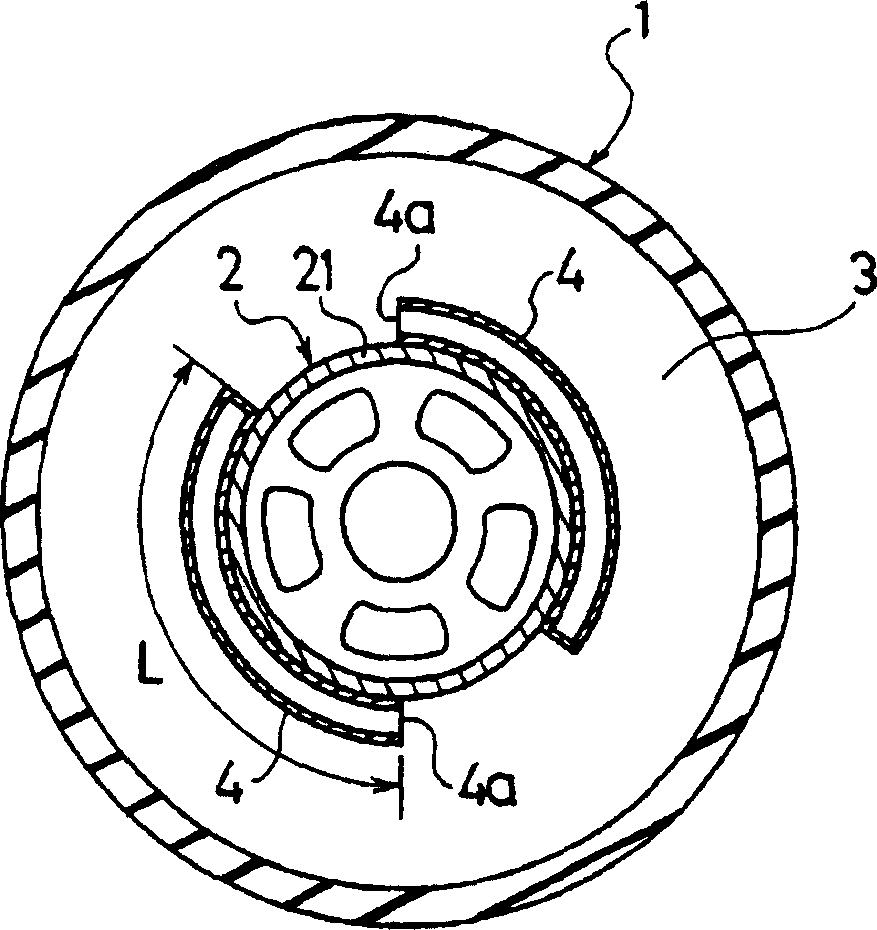

[0031] Below, while referring to the attached Figure 1 The configuration of the present invention will be described in detail.

[0032] figure 1 It is a figure which schematically shows the tire wheel assembly of this invention. exist figure 1 Among them, 1 is the pneumatic tire and 2 is the wheel. The wheel 2 includes a rim 21 fitted to the pneumatic tire 1 . Furthermore, a cavity 3 is formed between the pneumatic tire 1 and the rim 21 of the wheel 2 . Furthermore, two pipes 4, 4 are formed on the tire and wheel assembly so as to open to the cavity.

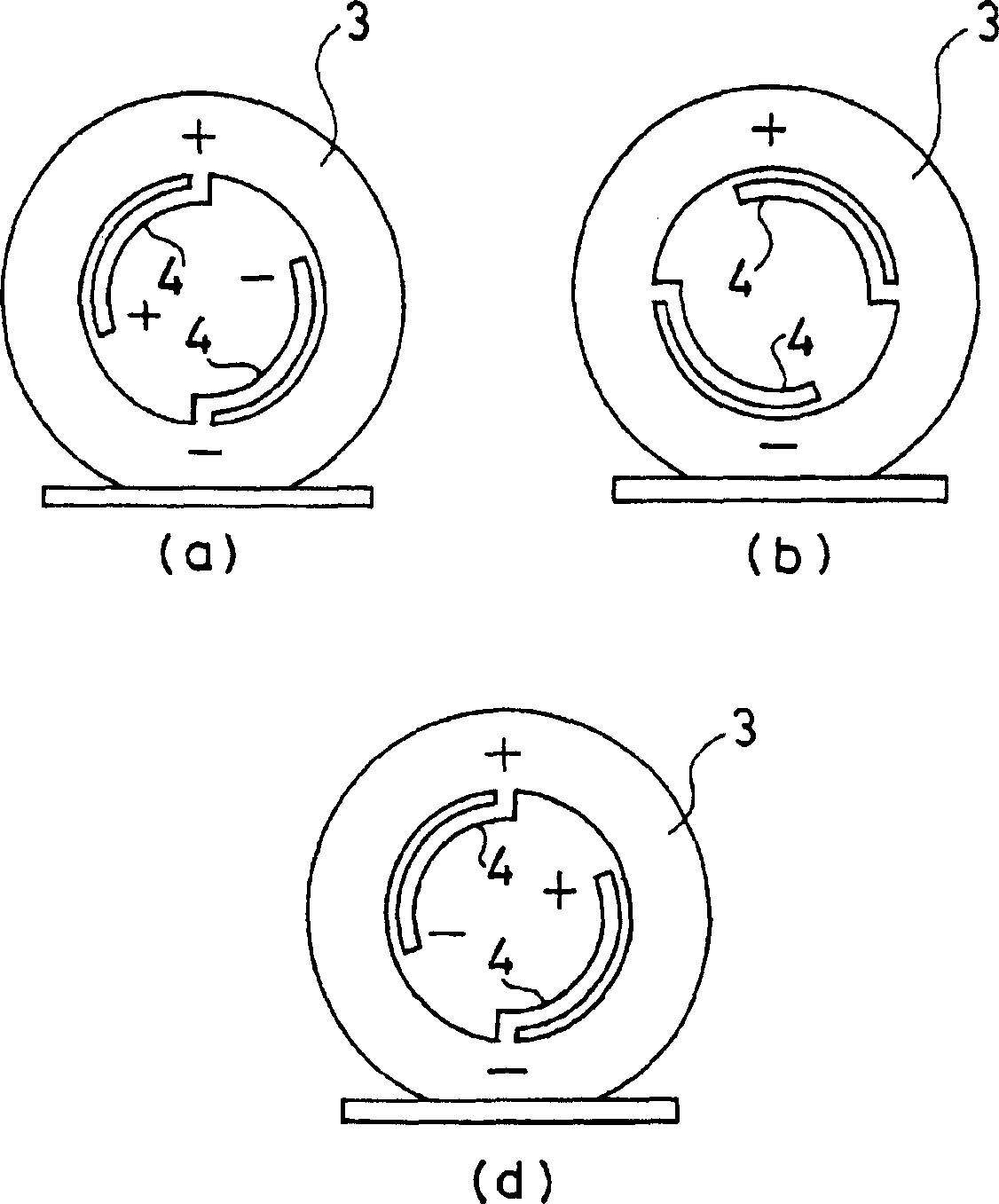

[0033] Each tube 4 has a reference length L approximately equivalent to 1 / 4 of the cavity resonance wavelength λ 0 length L, while one end is closed. The openings 4a of these tubes 4 are arranged at any one location on the circumference or at two opposing locations across the tire rotation axis.

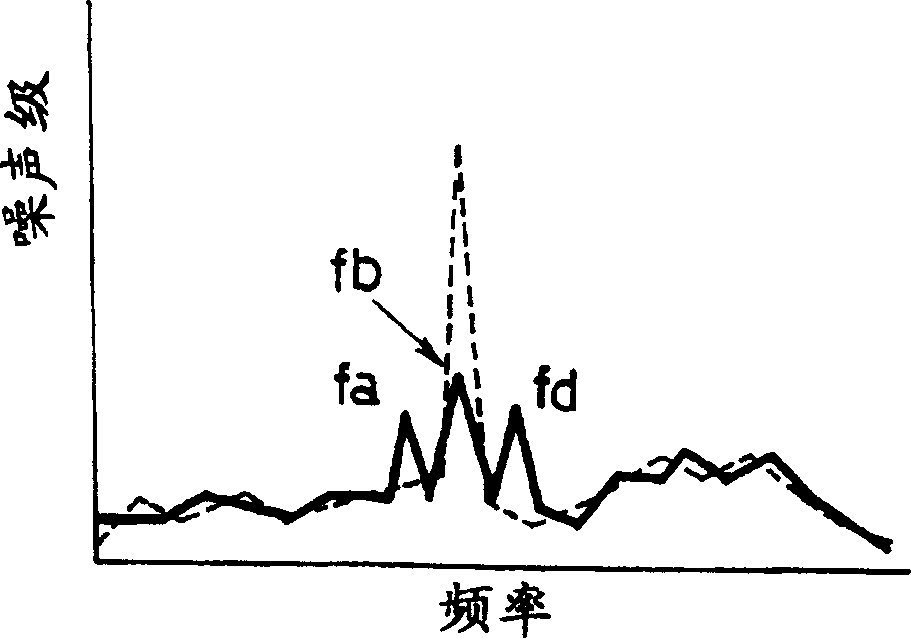

[0034] In the tire and wheel assembly constituted as described above, the vibration in the cavity 3 interferes with the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com