Noise reduction device for automobile engine

An automotive engine and noise reduction technology, applied in engine components, machines/engines, exhaust devices, etc., can solve the problems of high production cost, difficult to meet production needs, heavy mufflers, etc., to reduce noise, increase the reduction effect, and reduce collision. Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

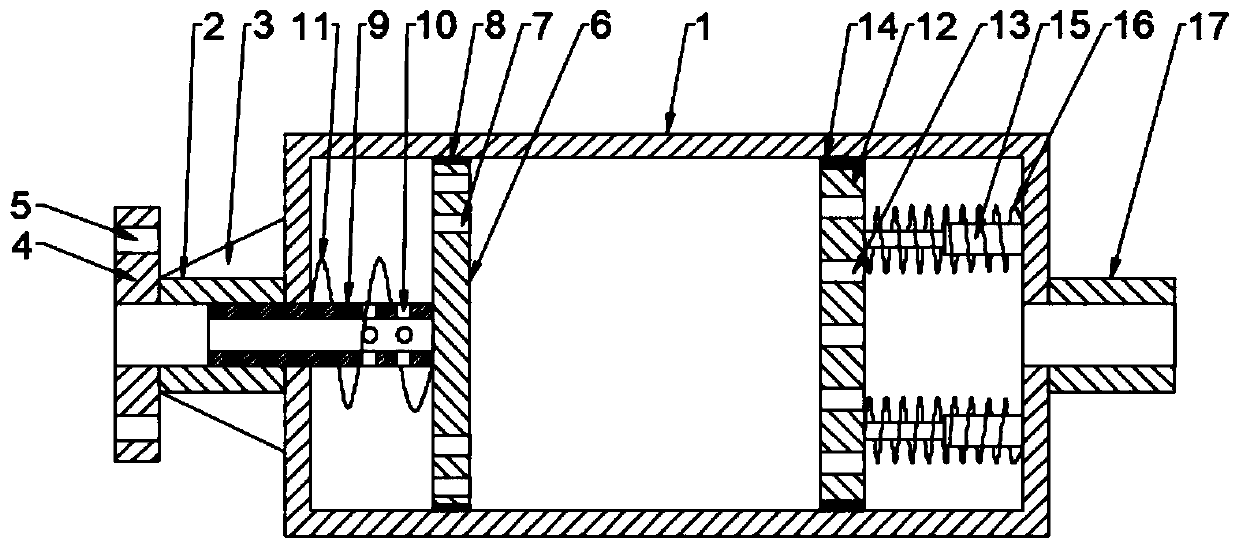

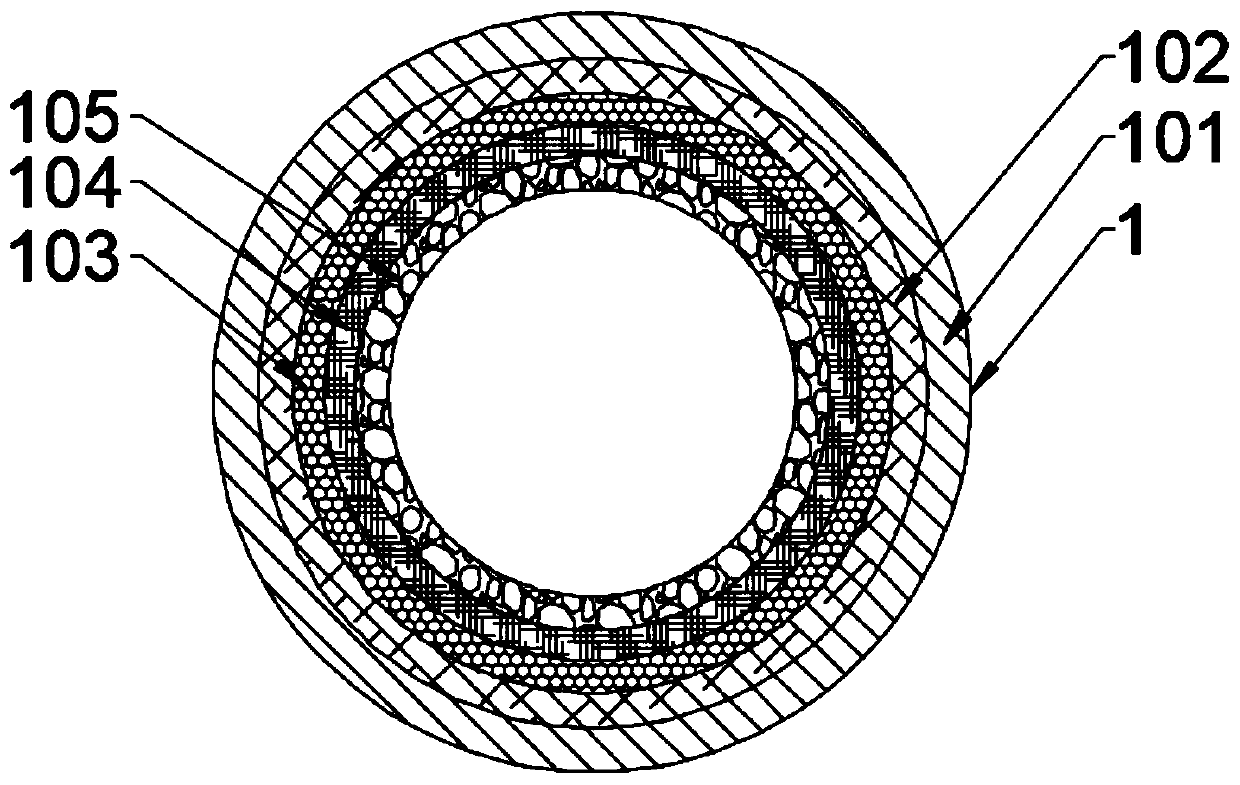

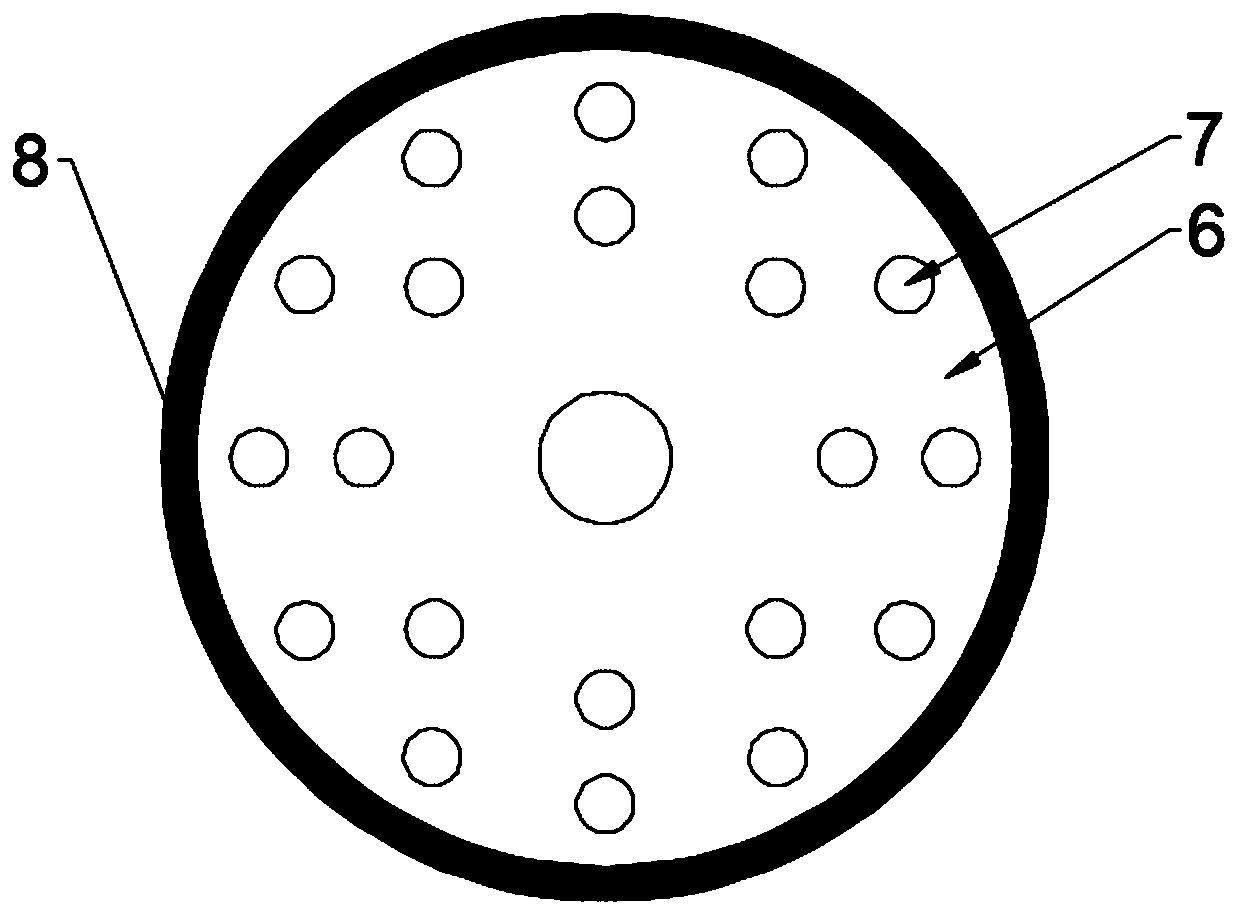

[0030] see Figure 1~4 , a noise reduction device for an automobile engine, comprising a noise reduction housing 1, an air intake pipe 2 and an air outlet pipe 17, the noise reduction housing 1 is a circular tube structure, and the left end of the noise reduction housing 1 is connected to the air intake pipe 2. The right end of the noise reduction housing 1 is connected to the air outlet pipe 17. The axis of the noise reduction housing 1 coincides with the axis of the intake pipe 2 and the axis of the air outlet pipe 17. The noise reduction housing 1 includes an outer shell 101, Sound-insulating layer 102, sound-absorbing layer 103, temperature-insulating layer 104 and high-temperature-resistant layer 105, the inner wall of the outer casing 101 is provided with a sound-insulating layer 102, and the sound-insulating layer 102 is made of a sound-insulating board, and the sound-insulating layer The inner cavity wall of 102 is provided with a sound-absorbing layer 103, the inner c...

Embodiment 2

[0034]This embodiment is further elaborated on the basis of Embodiment 1. The other side end of the inlet pipe 2 is connected to the connection flange 4, and the connection flange 4 is uniformly provided with several threaded holes 5. The outer circular surface of the trachea 2 is arranged in a circular array with a number of reinforcing ribs 3 matching with the noise reduction housing 1. Through the setting of the connecting flange 4, the disassembly and assembly of the entire device is improved, which is convenient for later maintenance and disassembly; Moreover, by providing the rib plate 3, the rigidity of the intake pipe 2 is improved, which facilitates the cantilever installation of the noise reduction housing 1, and improves the stability of the entire device.

[0035] The working principle of Embodiment 1-2, when the present invention is used, the exhaust gas enters the air guide pipe 9 through the intake pipe 2, then enters the left side of the inner cavity of the nois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com