Fast repairing method of internal screw

A technology of internal thread and internal thread sleeve, which is applied in the field of quick repair of internal thread, can solve problems such as repairing difficult threaded holes, and achieve the effects of improving repair speed, reducing repair workload, and reducing workpiece scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

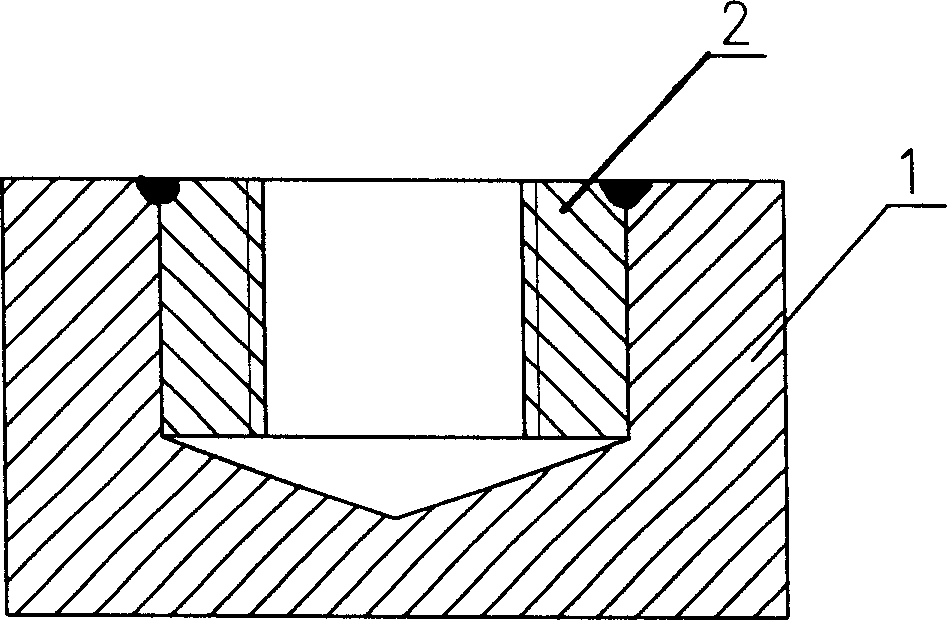

[0011] as attached figure 1 The internal thread quick repair method, first reaming the worn original threaded hole on the workpiece 1; then prepare the internal thread sleeve 2, the internal thread of the internal thread sleeve 2 is adapted to the original bolt, and the outer diameter of the internal thread sleeve is consistent with that on the workpiece The diameter of the reamed hole is matched; then the internal thread sleeve is placed in the reamed hole, and the mouth of the matching part is fixed by welding to prevent the internal thread sleeve from rotating or falling off relative to the workpiece. Before welding, the inner opening of the workpiece 1 and / or the outer opening of the internally threaded sleeve 2 may be chamfered to facilitate welding, and ground after welding.

specific Embodiment 2

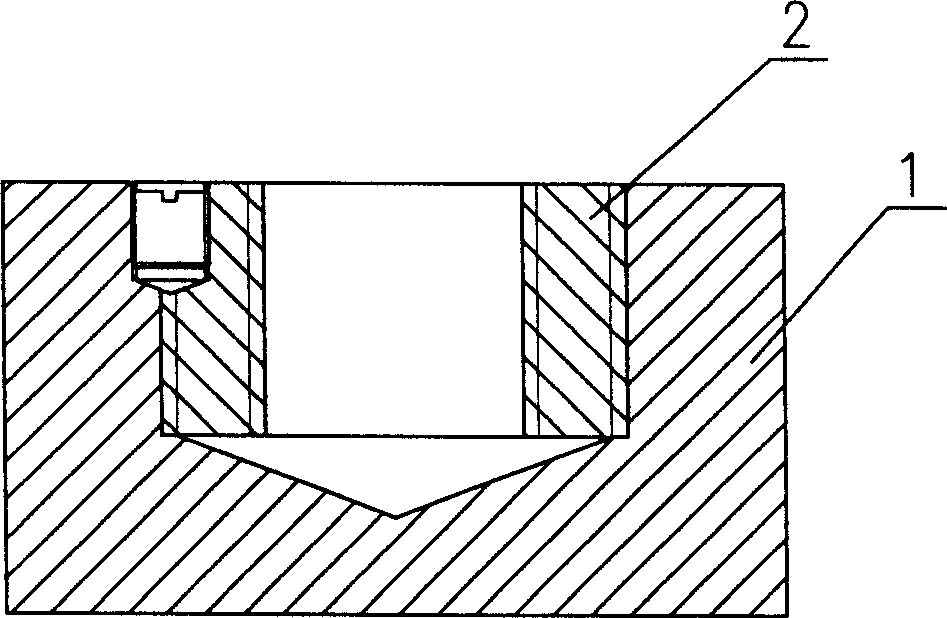

[0012] as attached figure 2 The quick repair method of the internal thread, first reaming and tapping the worn original thread hole on the workpiece 1; then prepare the internal thread sleeve 2, the internal thread of the internal thread sleeve 2 is adapted to the original bolt, and the outer diameter of the internal thread sleeve is processed The thread matches the reaming and tapping on the workpiece; after the cooperation, a small threaded hole is axially arranged at the mouth of the thread and then a small screw is screwed in to prevent the internal thread sleeve 2 from rotating or falling off relative to the workpiece 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com