Adhesive sheet and process for preparing it and method for processing the product

A technology of adhesive sheets and products, applied in the direction of adhesive products, adhesive types, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

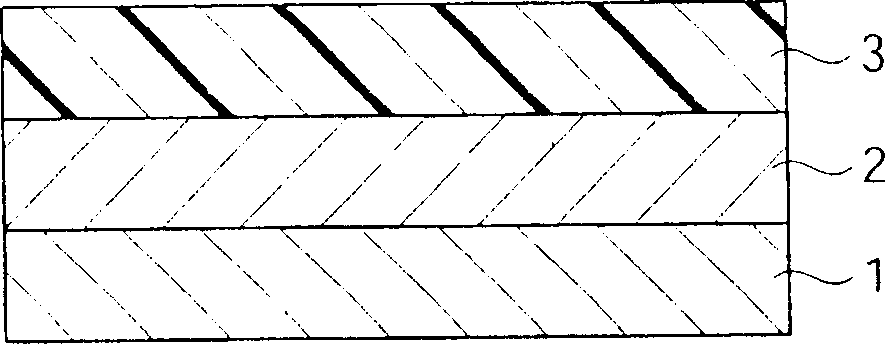

Image

Examples

Embodiment 1

[0078] In a reactor equipped with a condenser, a thermometer and a stirring device, 100 parts of 2-ethylhexyl acrylate, 10 parts of acrylic acid are used as acrylic monomers, and 0.35 parts of 1-hydroxycyclohexyl phenyl ketone (registered Trademark "Irugakuyua 184", produced by Chiba Specialty Chemical Co., Ltd.) and 0.35 parts of 2,2-dimethoxy-1,2-diphenylethan-1-one (registered trademark "Irugakuyua 651", Chiba Specialty Chemical Co., Ltd.) was used as a photopolymerization initiator, and a prepolymer-containing slurry was produced by partially photopolymerizing and thickening by exposing it to ultraviolet rays under a nitrogen atmosphere.

[0079] Next, 0.2 parts of trimethylolpropane triacrylate was added as a polyfunctional monomer to the partially polymerized slurry, and after stirring, it was coated on a peel-treated PET film (thickness 38 μm) and made Its thickness after curing was 300 μm. The PET film (thickness 38 μm) that overlaps and covers through peeling treatme...

Embodiment 2

[0084] Except for using 100 parts of lauryl acrylate and 10 parts of acrylic acid as the acrylic monomer in Example 1, an intermediate layer was formed in the same manner as in Example 1, and an adhesive bonded with a substrate, an intermediate layer, and an adhesive layer in this order was produced. piece. In addition, the gel component of this intermediate layer was 71%. The same measurement and evaluation as in Example 1 were performed about the obtained intermediate layer and the pressure-sensitive adhesive sheet. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com