Method for jointing concrete between upper and lower layers of wall body in concrete

A concrete wall and lower layer technology, applied to walls, building components, buildings, etc., can solve the problems of material waste, affect the strength of the wall, increase the labor cost of wall construction, etc., to reduce material loss, improve work efficiency, and reduce labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The present embodiment is to build a plane concrete wall. The layered pouring of the concrete wall will be carried out as follows:

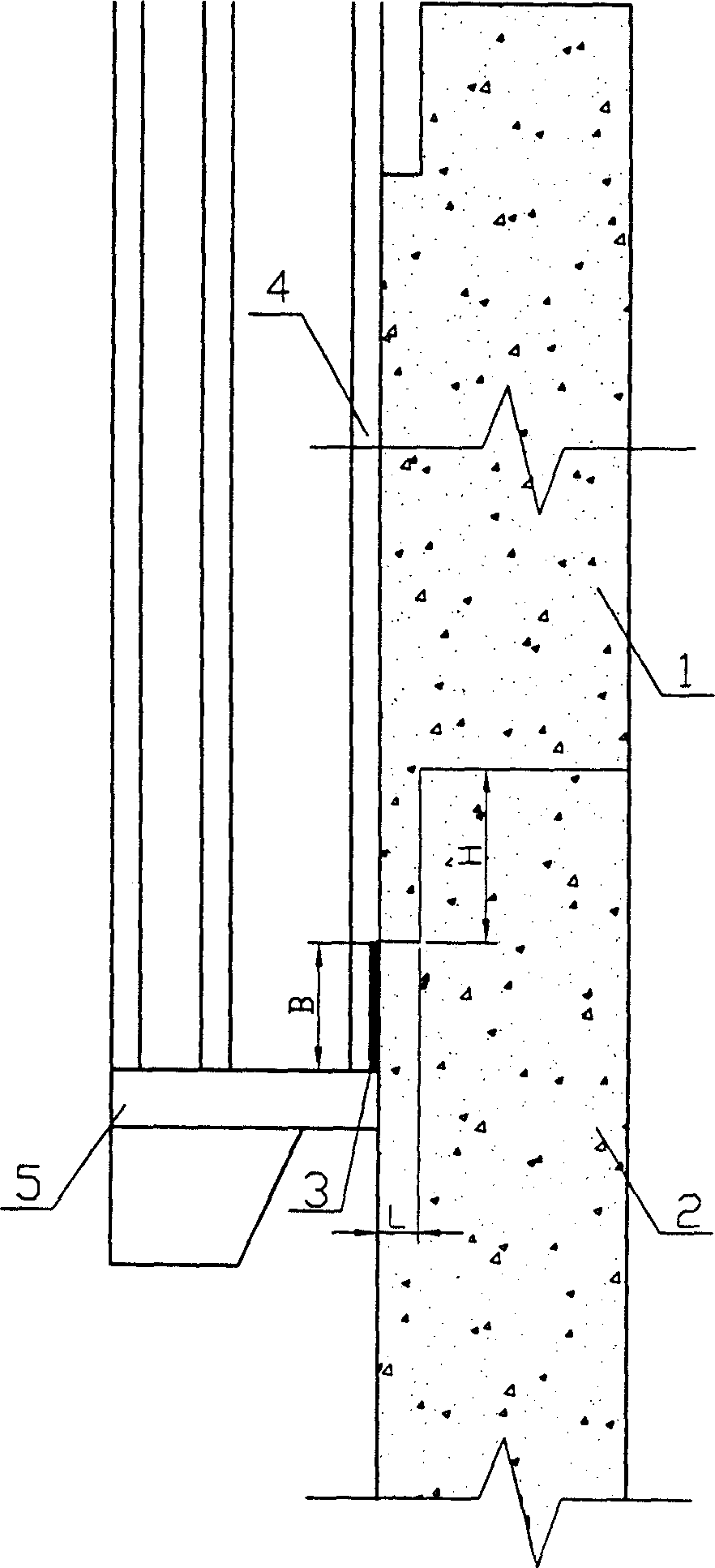

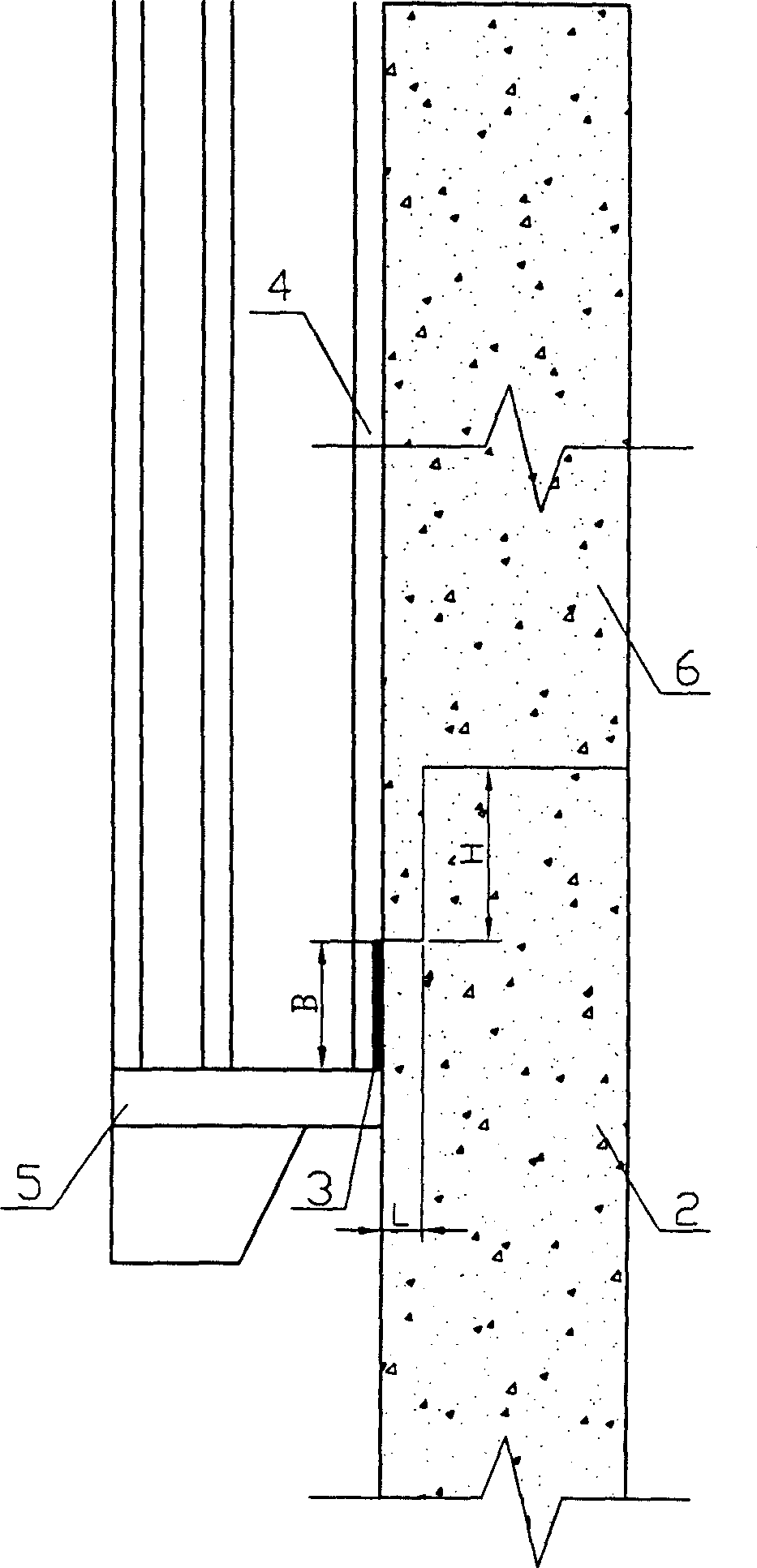

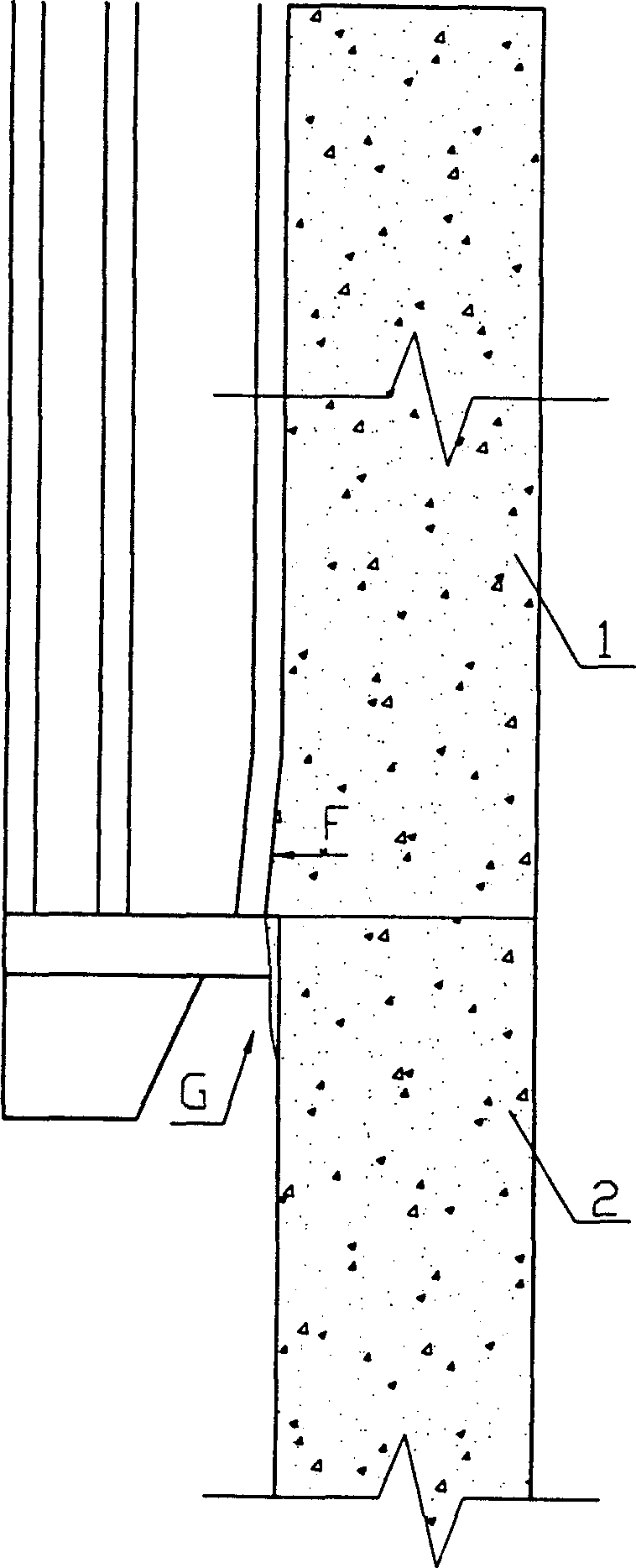

[0018] a. Except for the uppermost concrete layer of the wall, the upper end of each concrete layer is made into a rectangular gap with its outer side facing inward with a depth of L = 1.0 cm and a height of H = 20 cm through the template built. Please refer to figure 1 .

[0019] b. Paste a centimeter single-sided adhesive sponge strip with a width of B=2 along the outer edge of the above-mentioned gap.

[0020] c. Install the formwork for the upper concrete layer relative to the above concrete layer. After the installation is completed, pour concrete to form the upper concrete layer.

[0021] d. Remove the formwork of the upper concrete layer and remove all pasted single-sided adhesive sponge strips.

[0022] After repeating the above steps several times, the pouring of the wall reaches the highest layer of concrete layer. When build...

Embodiment 2

[0024] The present embodiment is to build a circular concrete wall. The layered pouring of the concrete wall will be carried out as follows:

[0025] a. Except for the uppermost concrete layer of the wall, the upper end of each concrete layer is made into a rectangular gap with the outer side facing inward with a depth of L = 1.5 cm and a height of H = 30 cm through the template built. Please refer to figure 1 , the rectangular notch is essentially a circular arc surface notch with a rectangular profile.

[0026] b. Paste a centimeter single-sided adhesive sponge strip with a width of B=2 along the outer edge of the above-mentioned gap;

[0027] c. Install the upper concrete layer formwork relative to the above concrete layer, after the installation is completed, pour concrete to form the upper concrete layer;

[0028] d. Remove the formwork of the upper concrete layer and remove all pasted single-sided adhesive sponge strips.

[0029] After repeating the above steps sever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com