Foaming instrument

A tool and shell technology, applied in the field of foaming tools, can solve the problems of insufficient sealing, high consumption of foaming tools, easy leakage or blockage, etc., and achieve the effect of convenient cleaning or replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

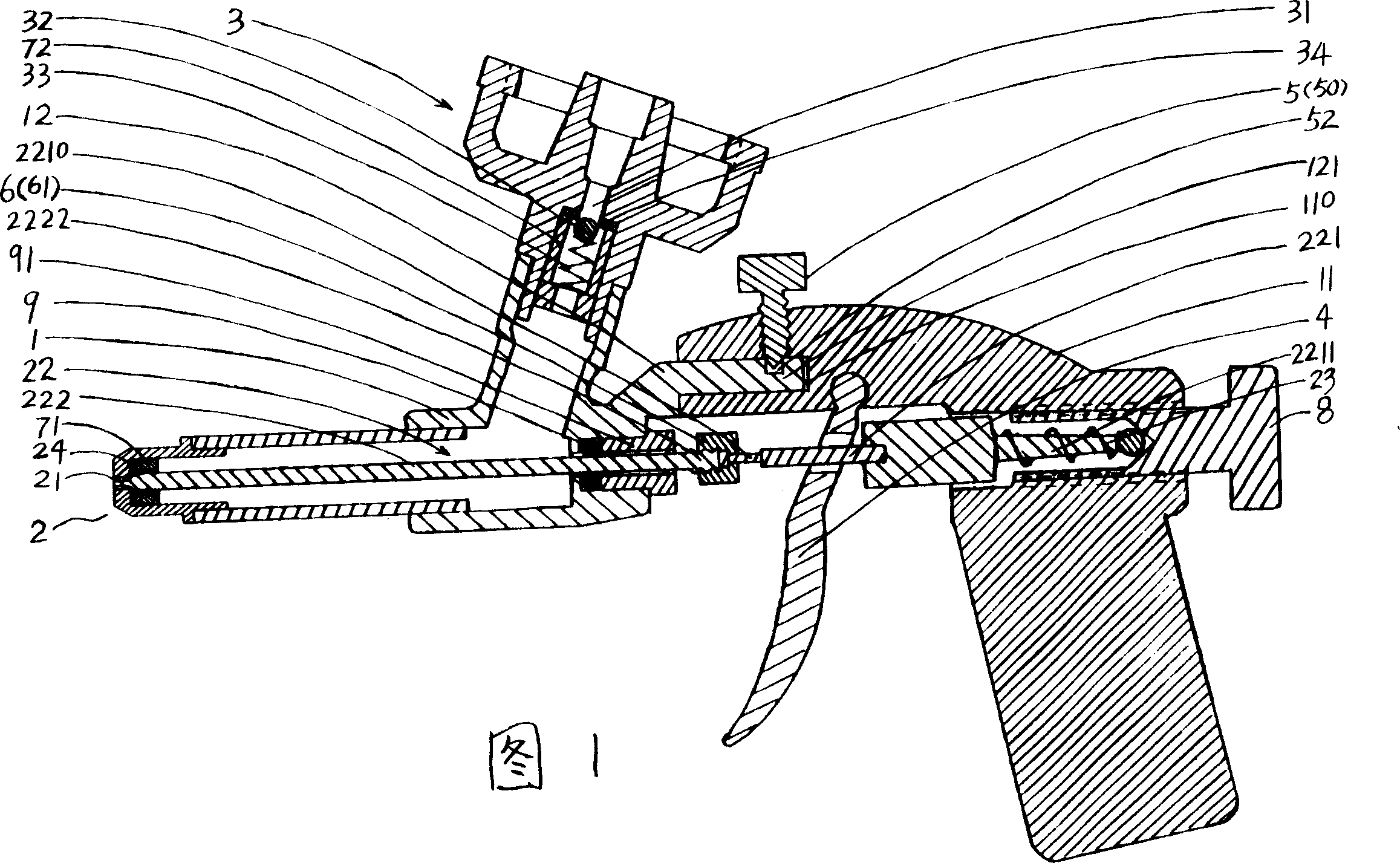

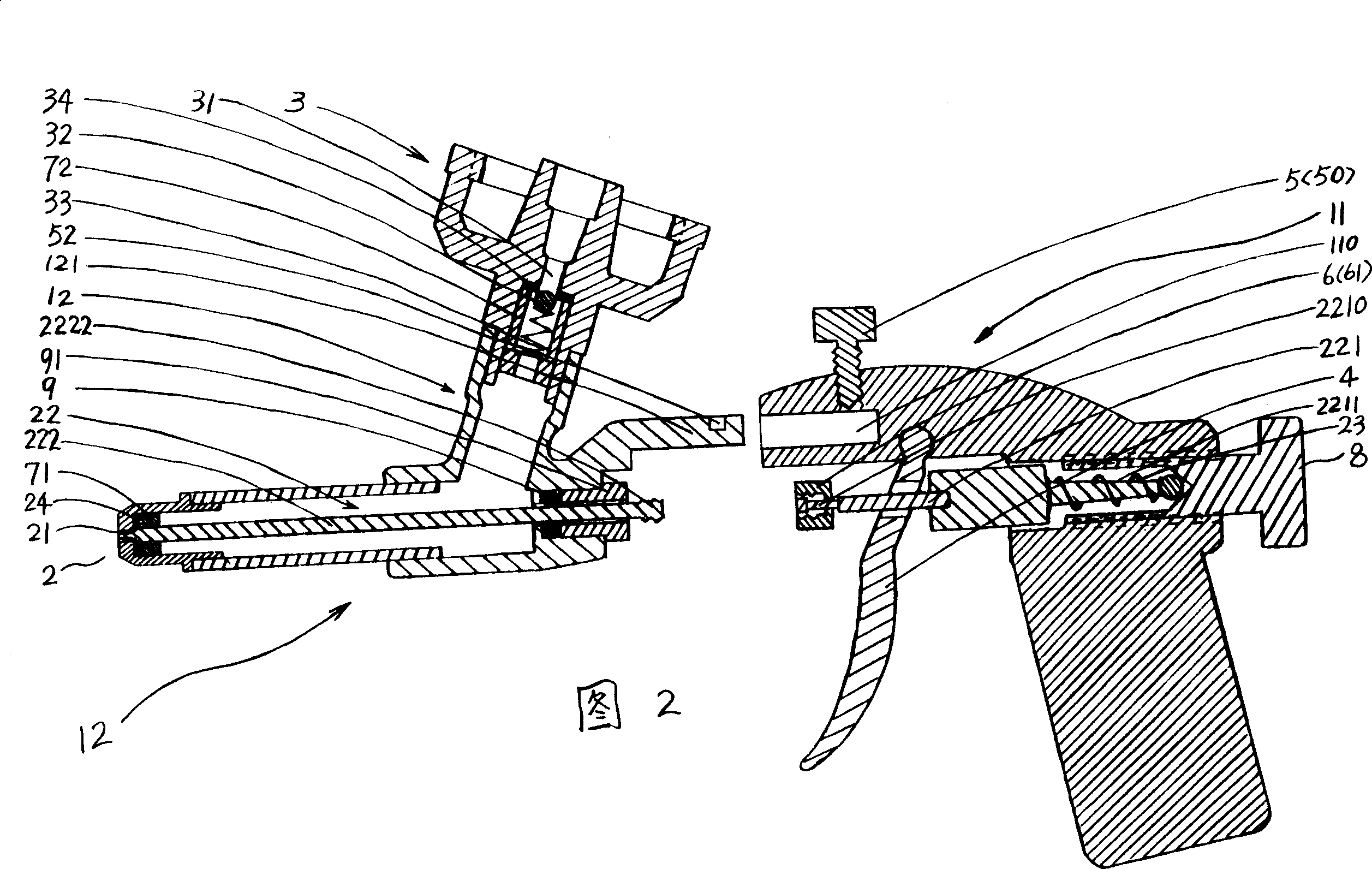

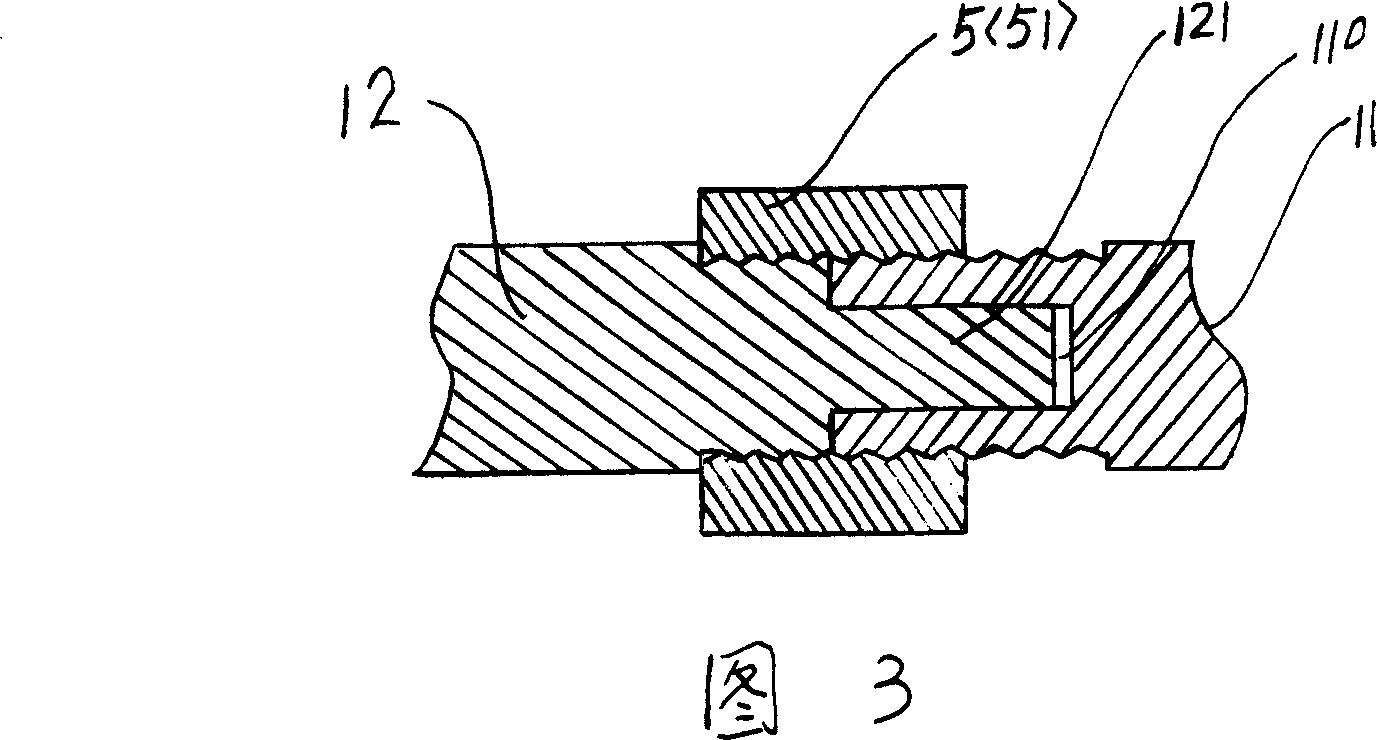

[0036] A foaming tool of the present invention, see Figures 1-6 and Figures 12-16, it includes a housing 1, a liquid outlet valve 2, a liquid inlet valve 3 and a switch device 4, the liquid outlet valve 2 and the liquid inlet valve 3 are installed In the housing 1, the switch device 4 can open or close the liquid outlet valve 2, and also includes at least one detachable or locking said at least part of the liquid outlet valve 2 and / or said at least part of the liquid outlet valve 2 on the housing 1. Part of the locking mechanism 5 of the liquid inlet valve 3, when the liquid outlet valve 2 or the liquid inlet valve 3 or the entire channel in the foaming tool leaks or is damaged or blocked, as long as the locking mechanism 5 is opened, at least Part of the liquid outlet valve 2 and / or at least a part of the liquid inlet valve 3 is arranged, and then cleaned or replaced with a new at least part of the liquid outlet valve 2 and / or the liquid inlet valve 3, and then the cleaned by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com