Vehicle component and method for making a vehicle component

A technology of vehicle components and components, applied in the direction of vehicle components, applications, upper structures, etc., can solve problems such as low matching, smoothness, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Before starting to describe many typical embodiments of the present invention in detail, it should be understood that the present invention is not limited to the details or methods described in the following description or shown in the accompanying drawings. The present invention may have other embodiments or be practiced or implemented in various ways. It should also be understood that the wording and terminology used herein are for descriptive purposes and should not be considered as limiting.

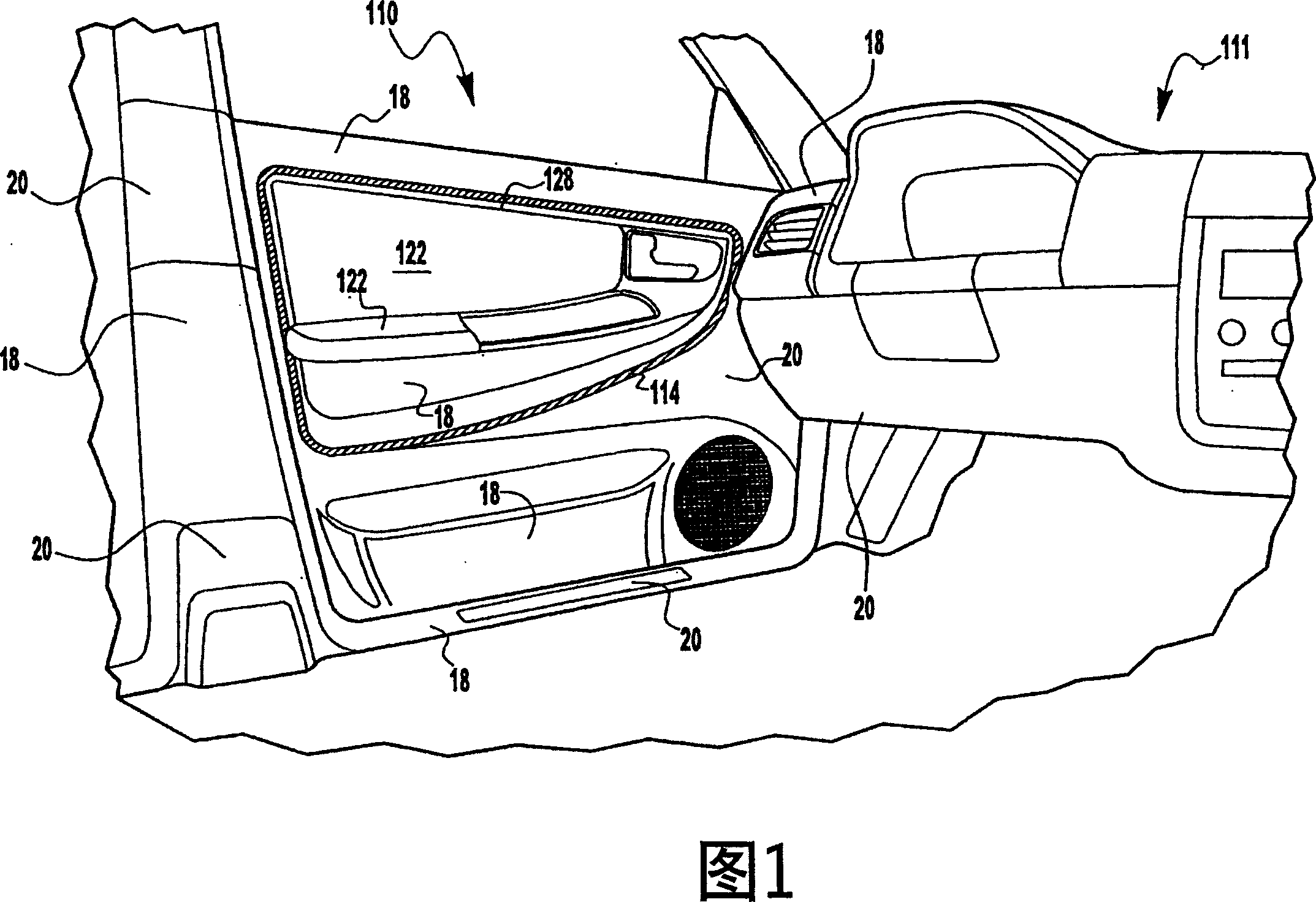

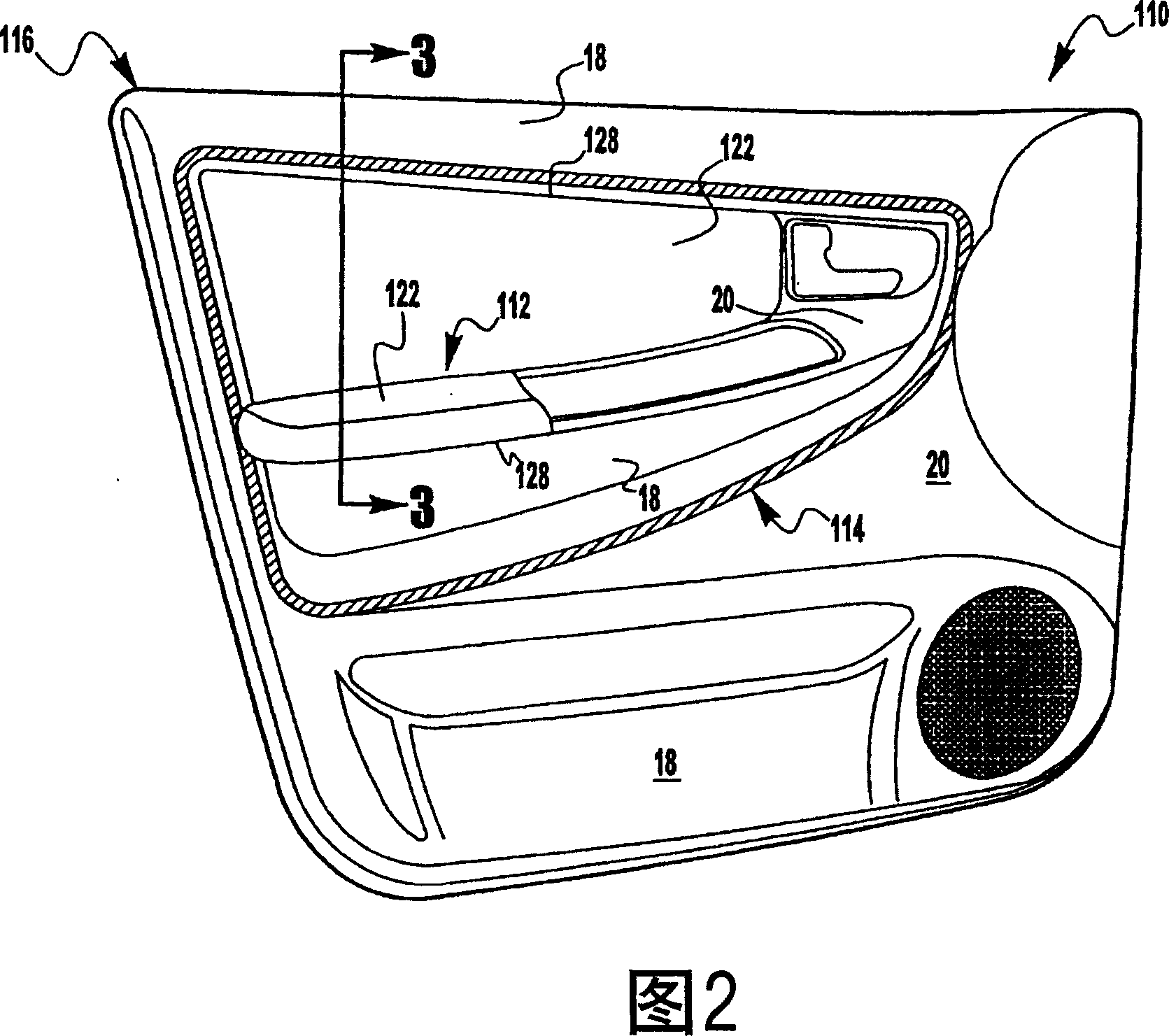

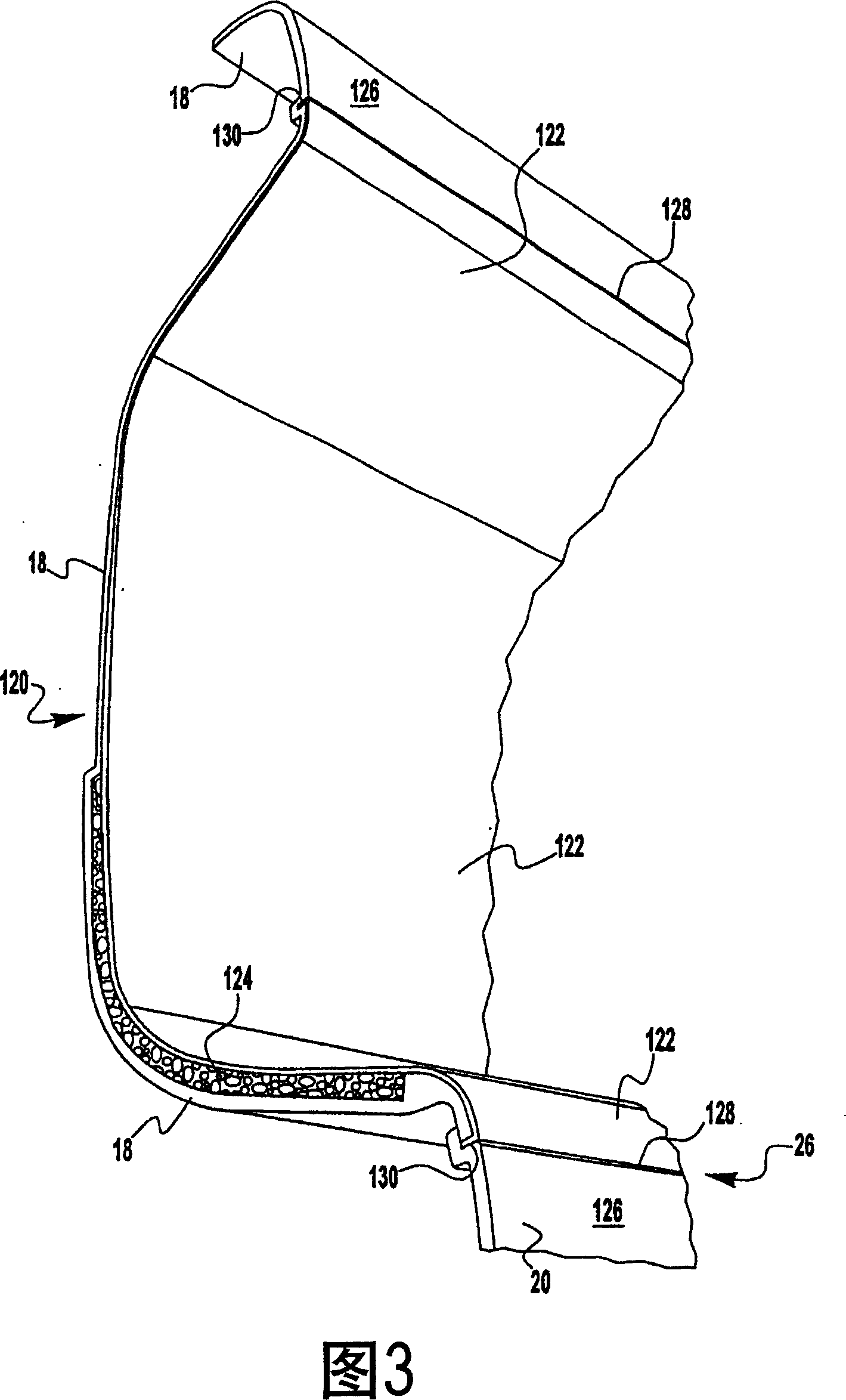

[0043]Generally, the parts or molded parts described in this disclosure are molded parts that have one or more partial or discrete soft or cushioned areas or portions. In one embodiment, the molded part is configured as a decorative panel for use in vehicles (e.g., automobiles such as cars, trucks, buses, etc.; airplanes, boats, etc.). Providing a decorative panel with one or more partial or scattered soft or cushioning areas or parts enables the decorative panel to selectively in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com