Cotton conditioner for a cotton harvester

A regulator and cotton technology, applied in the field of structure, can solve the problems of reducing the ability to contact and remove fibers, affecting separation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

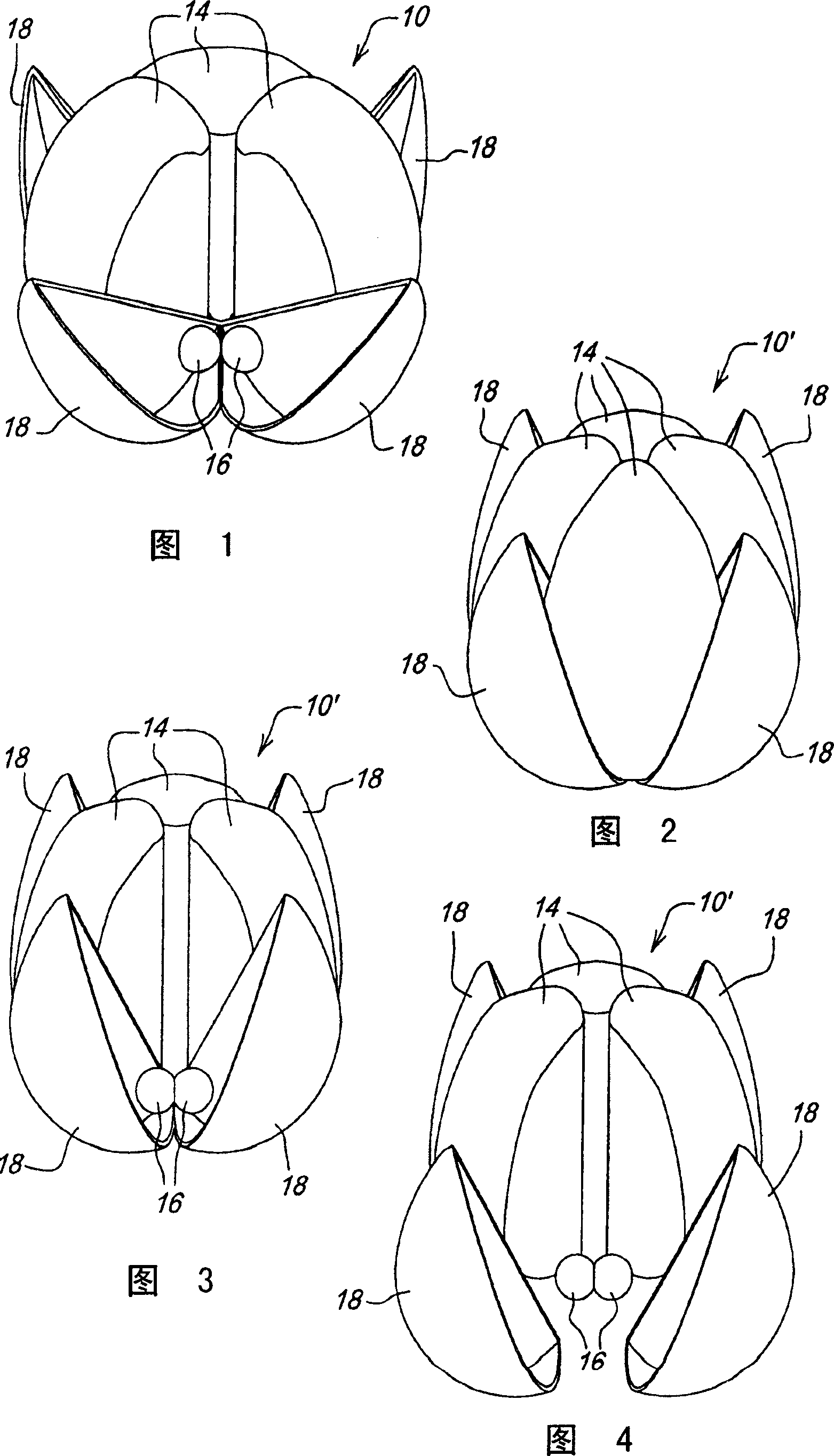

[0018] Referring now to Figure 1 , there is shown a cotton boll 10 from a cotton plant 12 . Cotton bolls 10 contain four groups or tufts 14 of cotton fibers attached to cotton seeds 16 . For the sake of clarity, one of the clusters 14 is removed in FIG. 1 . Tufts 14 are typically contained within burrs 18 when the cotton plant matures. As shown in accompanying drawing 1, when plant matures, burr 18 opens and exposes cotton fiber. However, there are still a large number of bolls that are not fully opened as shown in the accompanying drawings 2 and 3 of the cotton bolls 10'. The fiber on the partially opened boll 10' is not fully exposed, and the cottonseed 16 is still tightly wrapped.

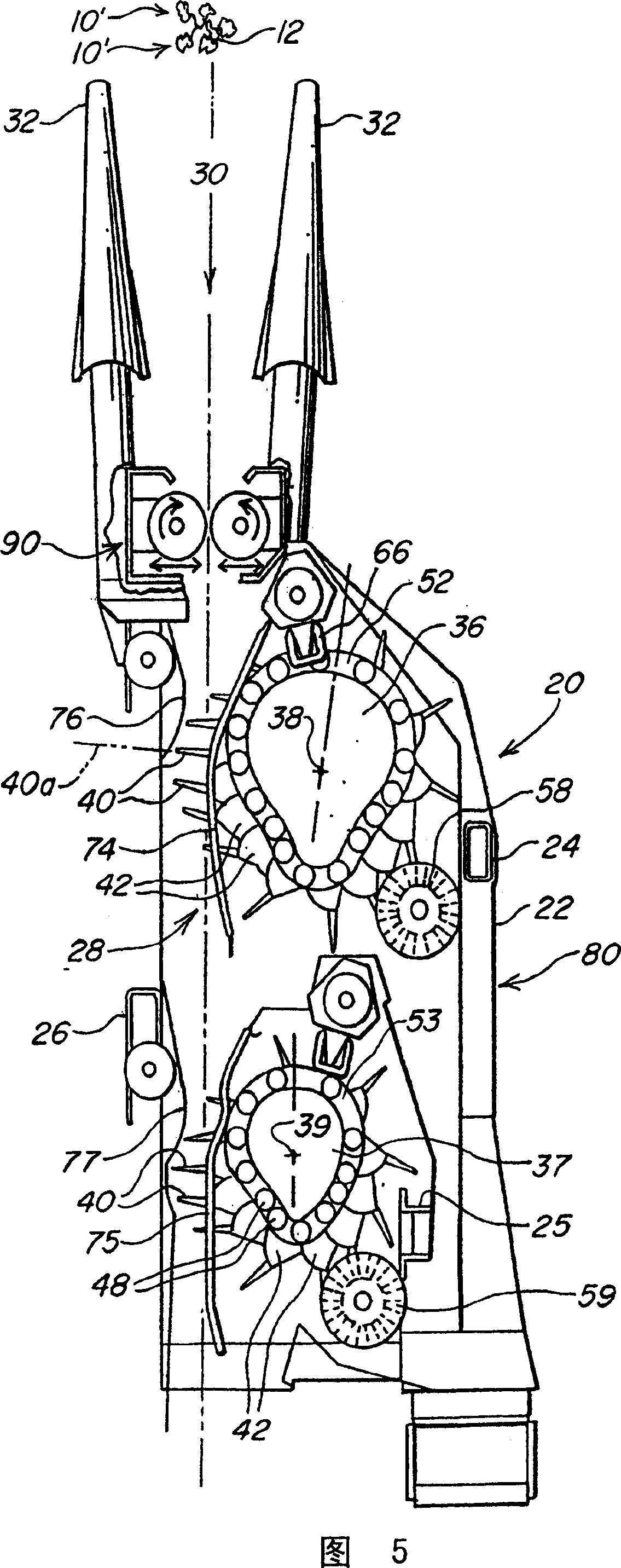

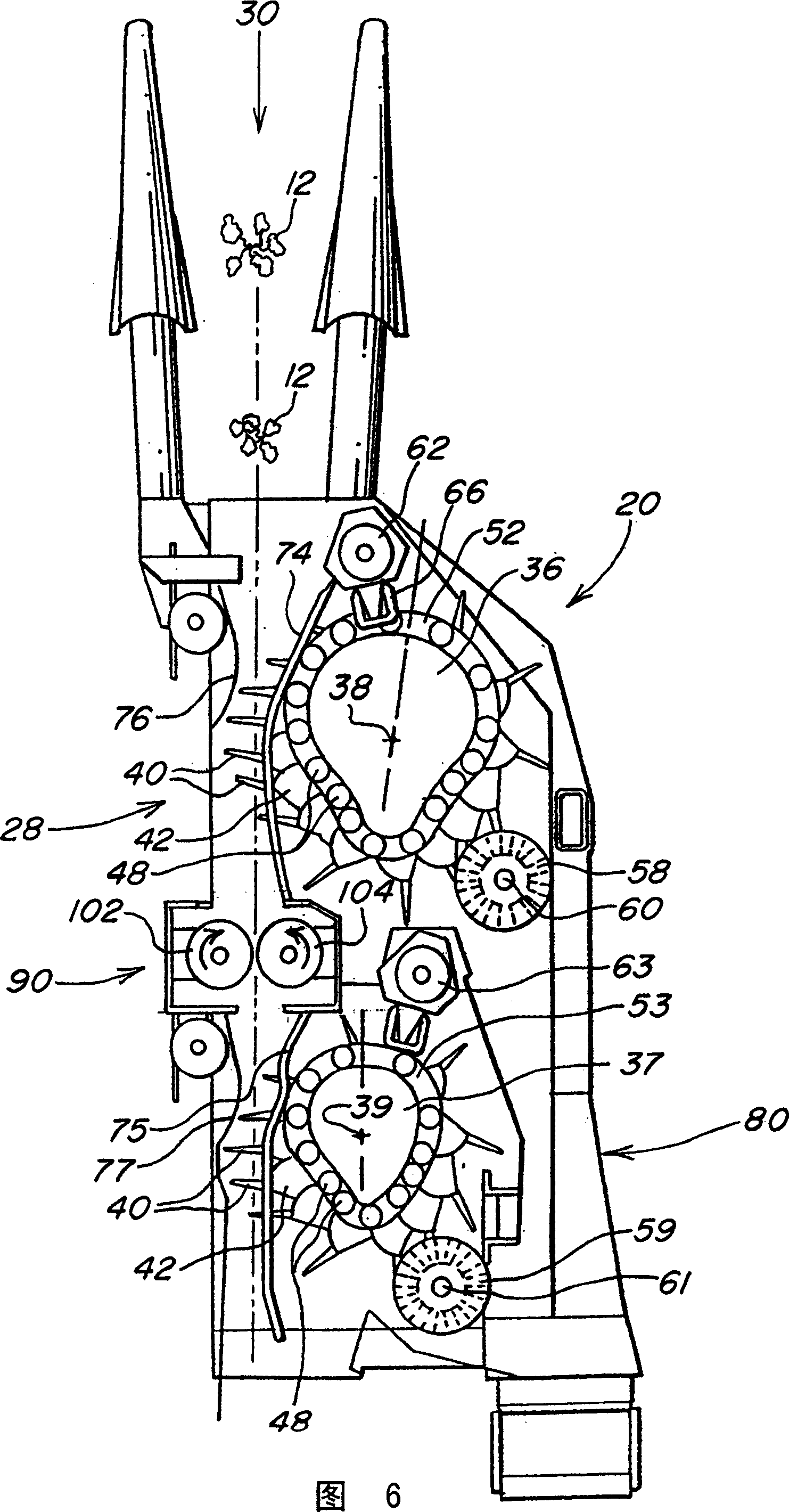

[0019] Referring now to accompanying drawing 5 accompanying drawing 6, wherein shows the row device 20 that cotton picking machine is useful. The row unit 10 has a shroud 22 with vertical members as shown at positions 24,25,26. A fore-and-aft extending row receiving area 20 is defined which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com