Multi-stage gasbag combination buffer unit

A technology of buffer device and air bag, which is applied to launch devices, transportation and packaging, aircraft parts, etc., can solve the problem of easy bursting of a single air bag, and achieve the effects of being suitable for mass production and use, convenient for deflated storage and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

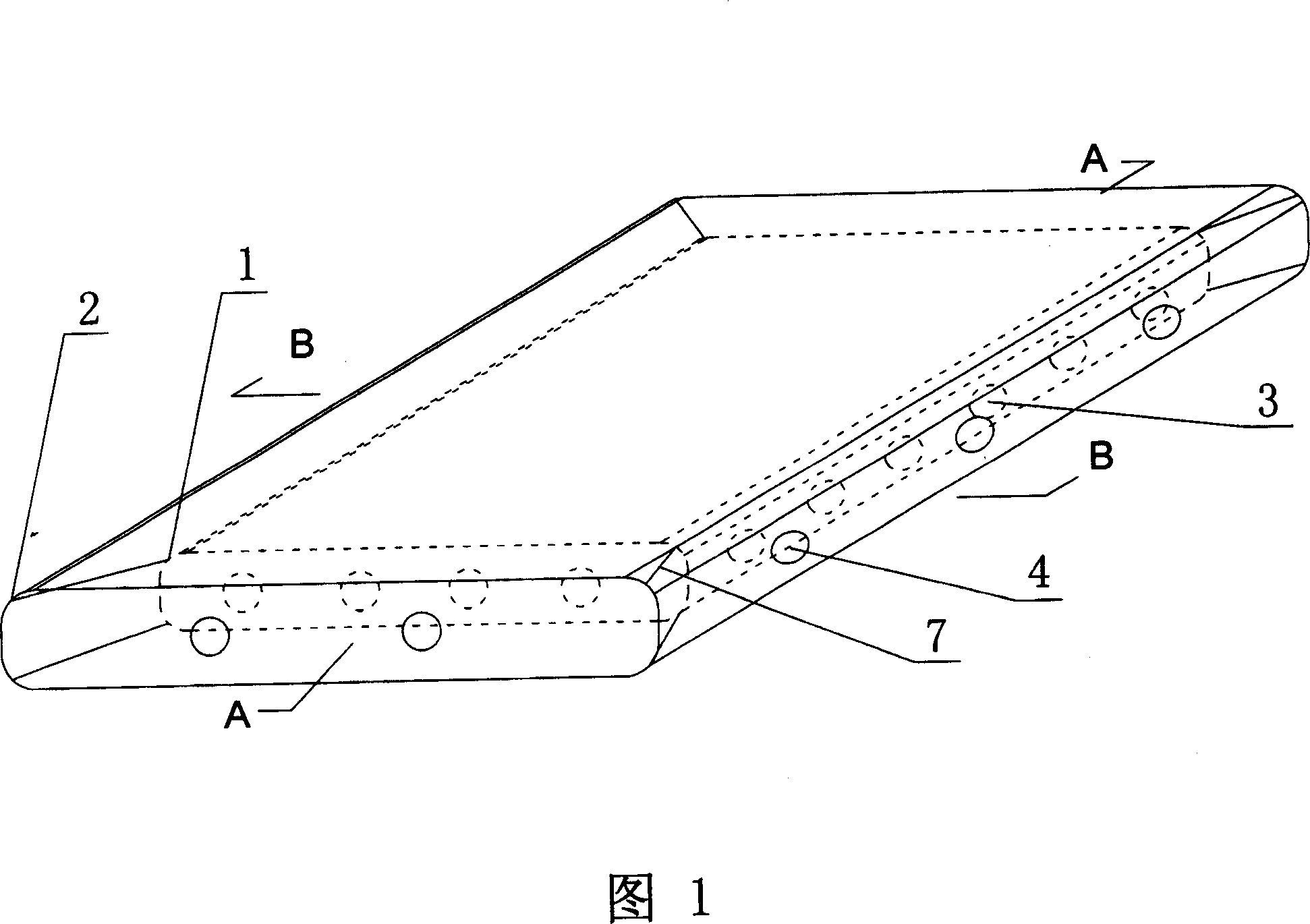

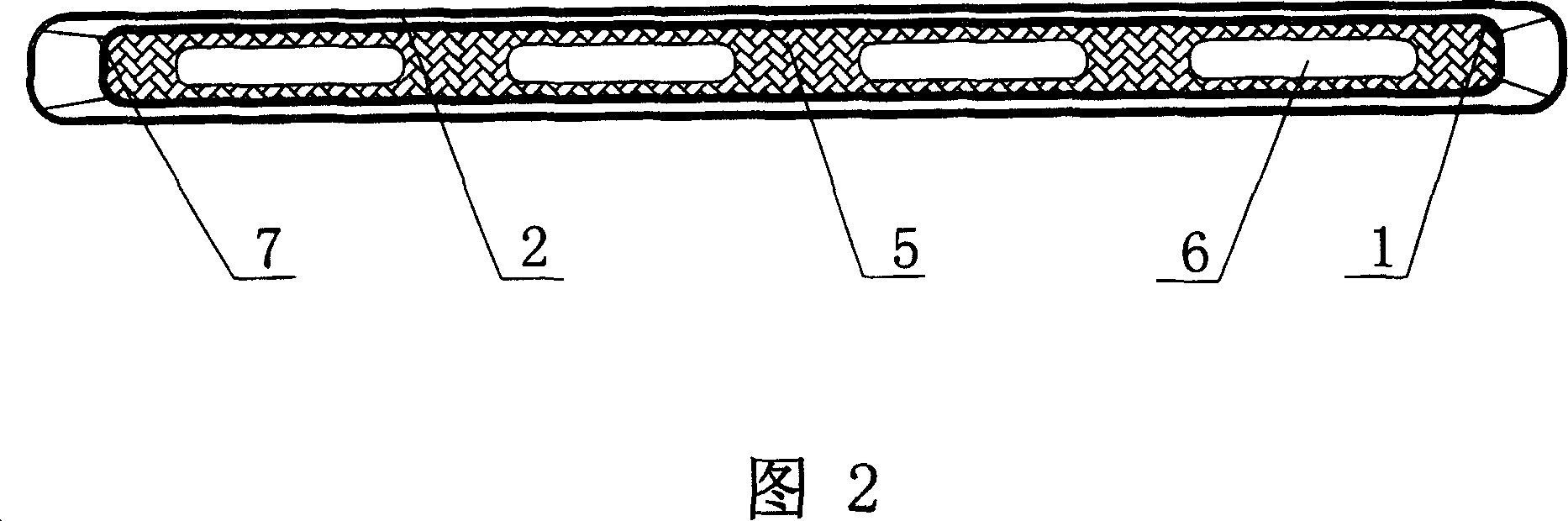

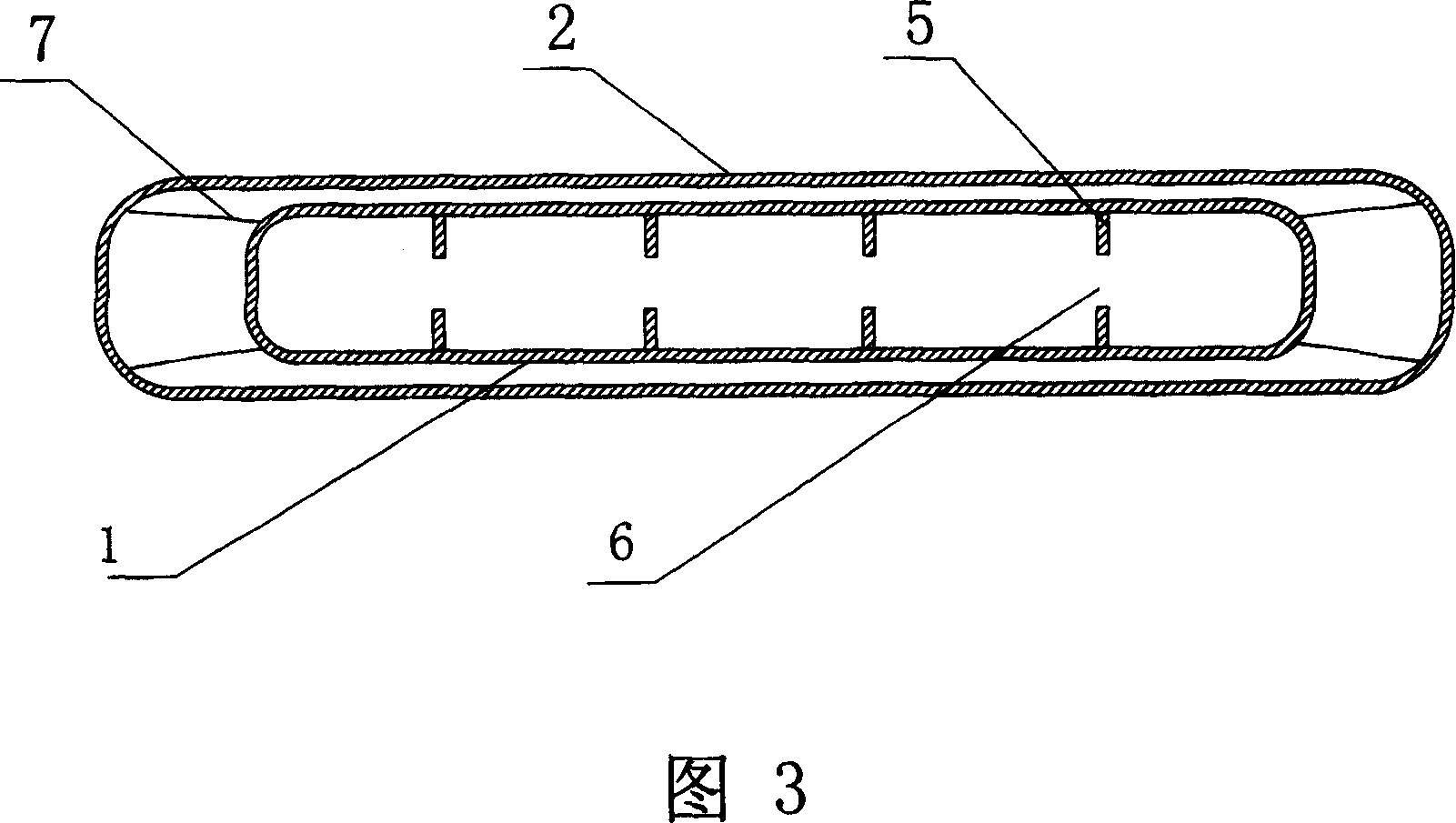

[0016] As shown in Fig. 1, Fig. 2 and Fig. 3, the multi-stage airbag joint cushioning device of the present invention includes an inner airbag 1 and one or more outer airbags 2 nested in sequence, and the outer airbag 2 is wrapped on the outside of the inner airbag 1 , the inner airbag 1 is an inflatable airbag that can be exhausted, and the outer airbags 2 at each level are exhaustable non-inflatable airbags. After the inner airbag 1 is inflated, its volume is smaller than that of the outer airbag 2, and its volume ratio can be determined according to the instantaneous energy absorption in actual working conditions. The airbag 1 and the outer airbag 2 are made of fiber cloth with certain strength and good airtightness, and there are no other mechanical accessories or filling materials, and only the air with low cost and environmental ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com