Electric motor using armature

A motor and armature technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of reduced reliability of the motor, adverse consequences, insufficient bonding force of the slot wedge 23, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] For convenience of description, the same reference numerals will continue to be used for the same or equivalent parts as those described or illustrated above.

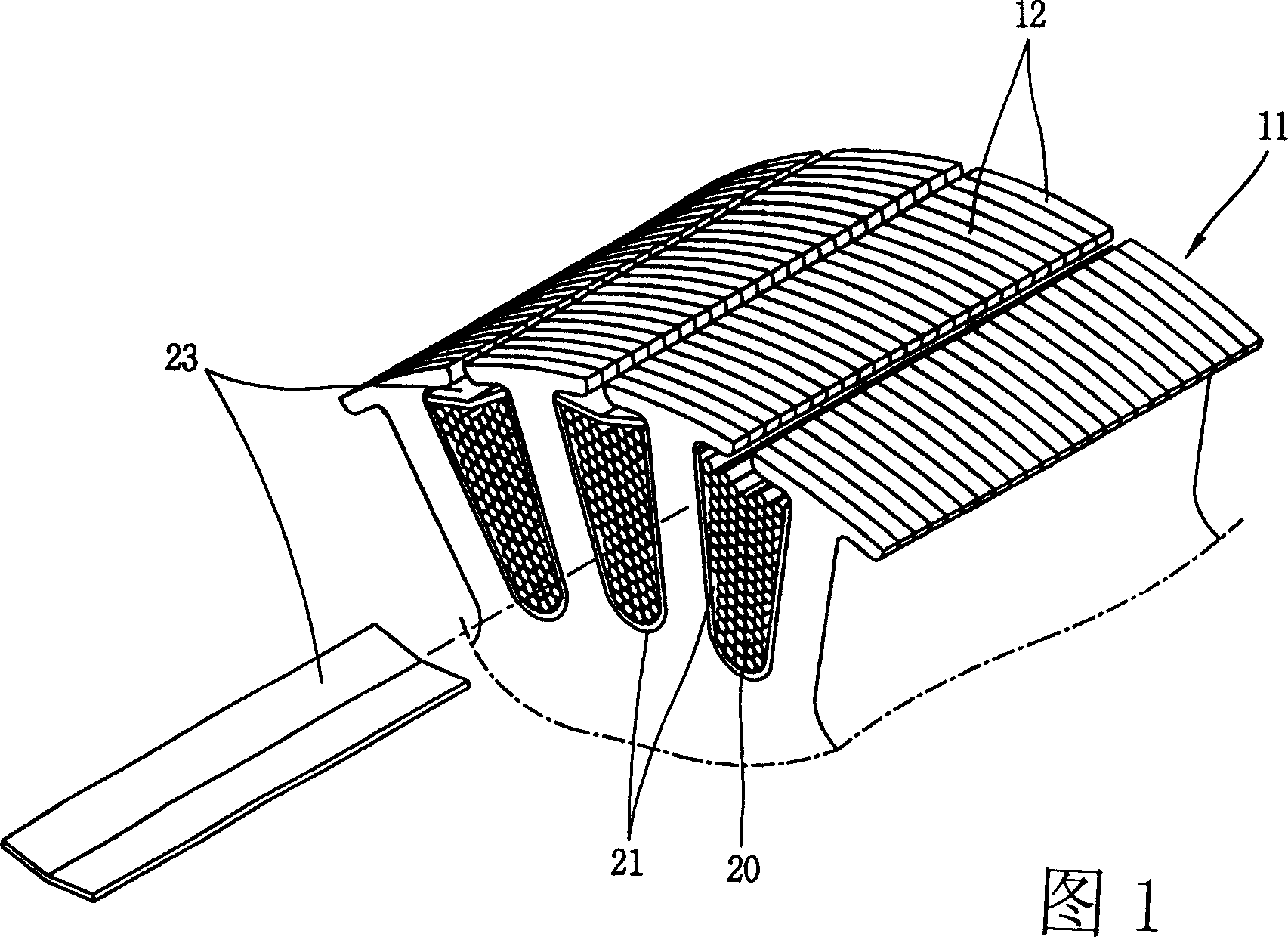

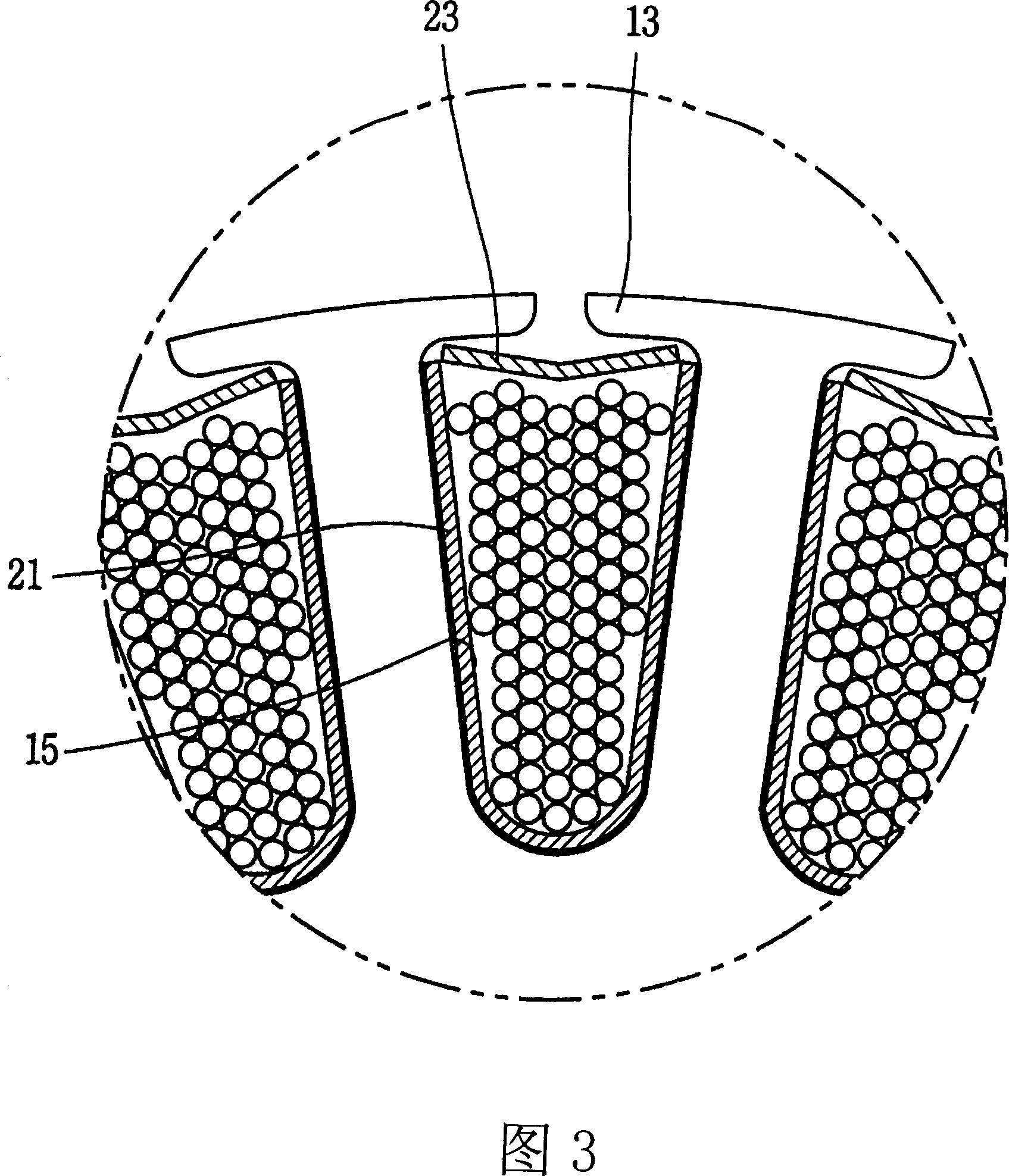

[0032] As shown in Figures 4 and 5, the motor armature 30 of the present invention includes the following parts: a magnetic core 11 having a plurality of slots 15 opening outward; a coil 20 wound inside the slots 15; Insulator, and when projected on a plane, it has a length extending from one side of the opening of the slot 15 along the inner wall to the other side, and then plays the role of insulating the slot insulating paper 31 between the magnetic core 11 and the coil 20 .

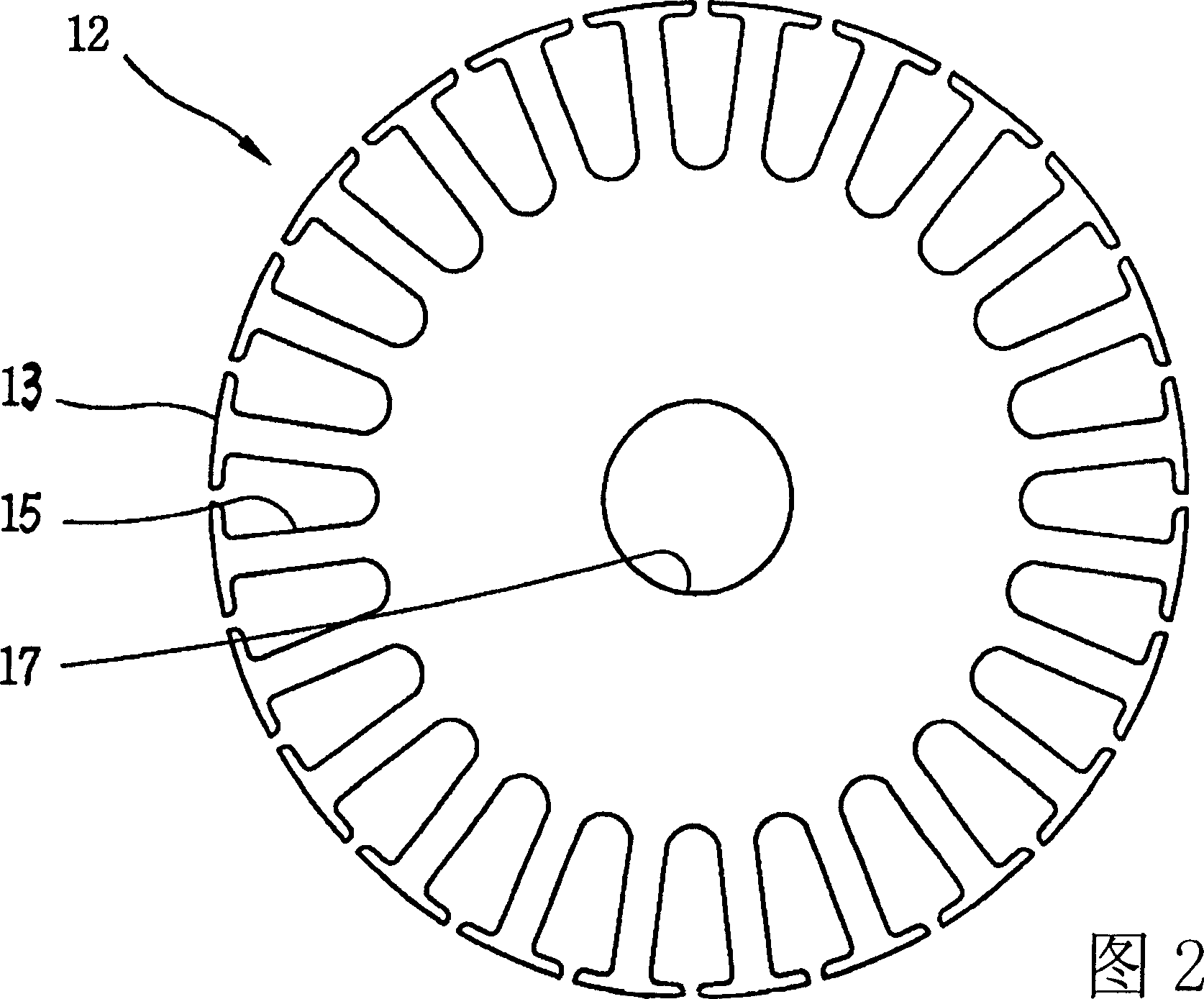

[0033] The magnetic core 11 is composed of a plurality of disk-shaped motor steel sheets 12 laminated insulatedly along the thickness direction. A shaft hole 17 capable of accommodating and connecting a rotating shaft is formed at the center of each motor steel plate 12 . The periphery of each motor steel plate 12 is formed with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com