Axial piston machine

A technology of axial pistons and machines, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machines, etc., can solve the problems of pressure and complex design of tank channels, etc., and achieve easy pipeline laying, low cost, and reduced noise emission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

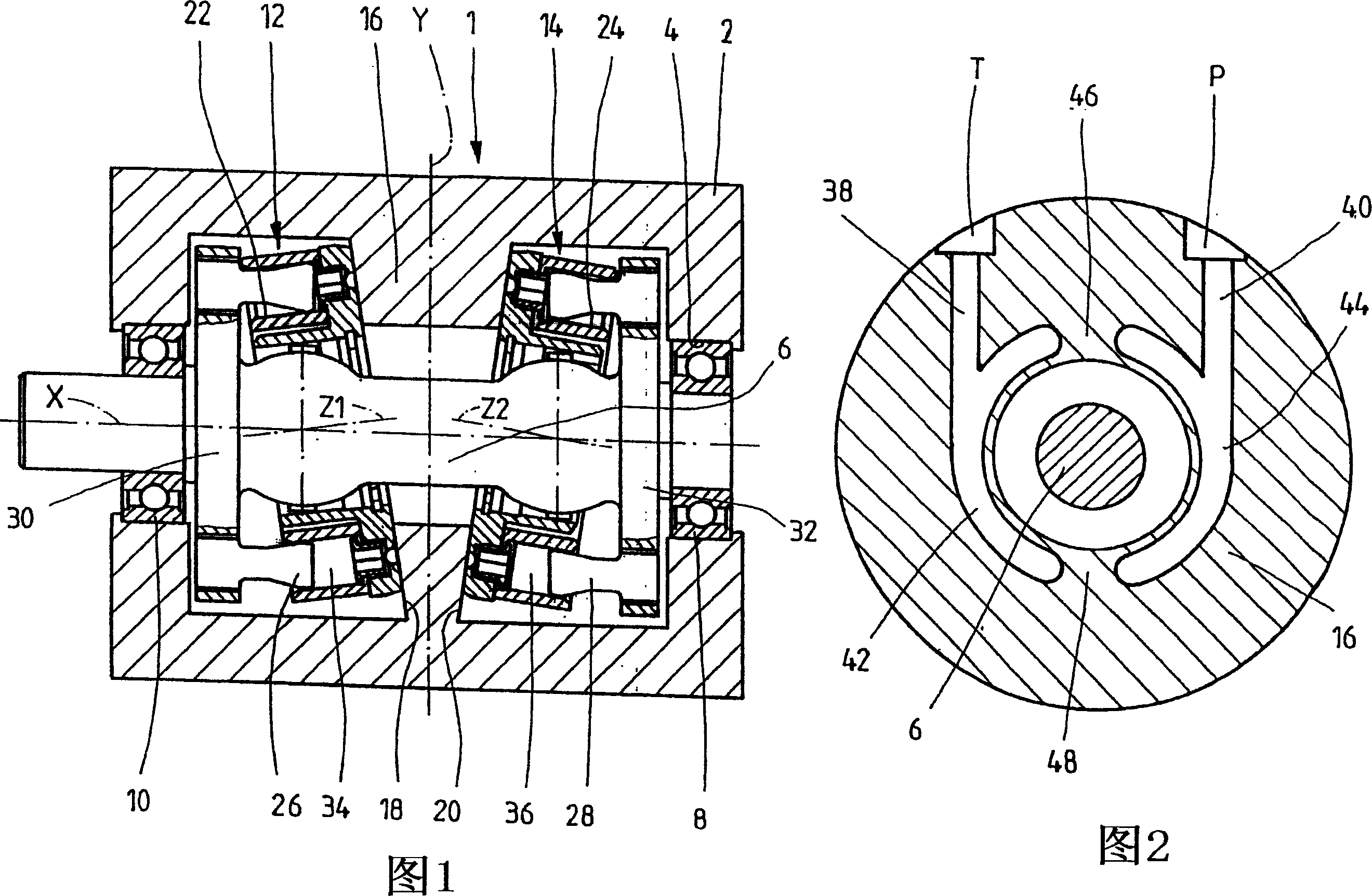

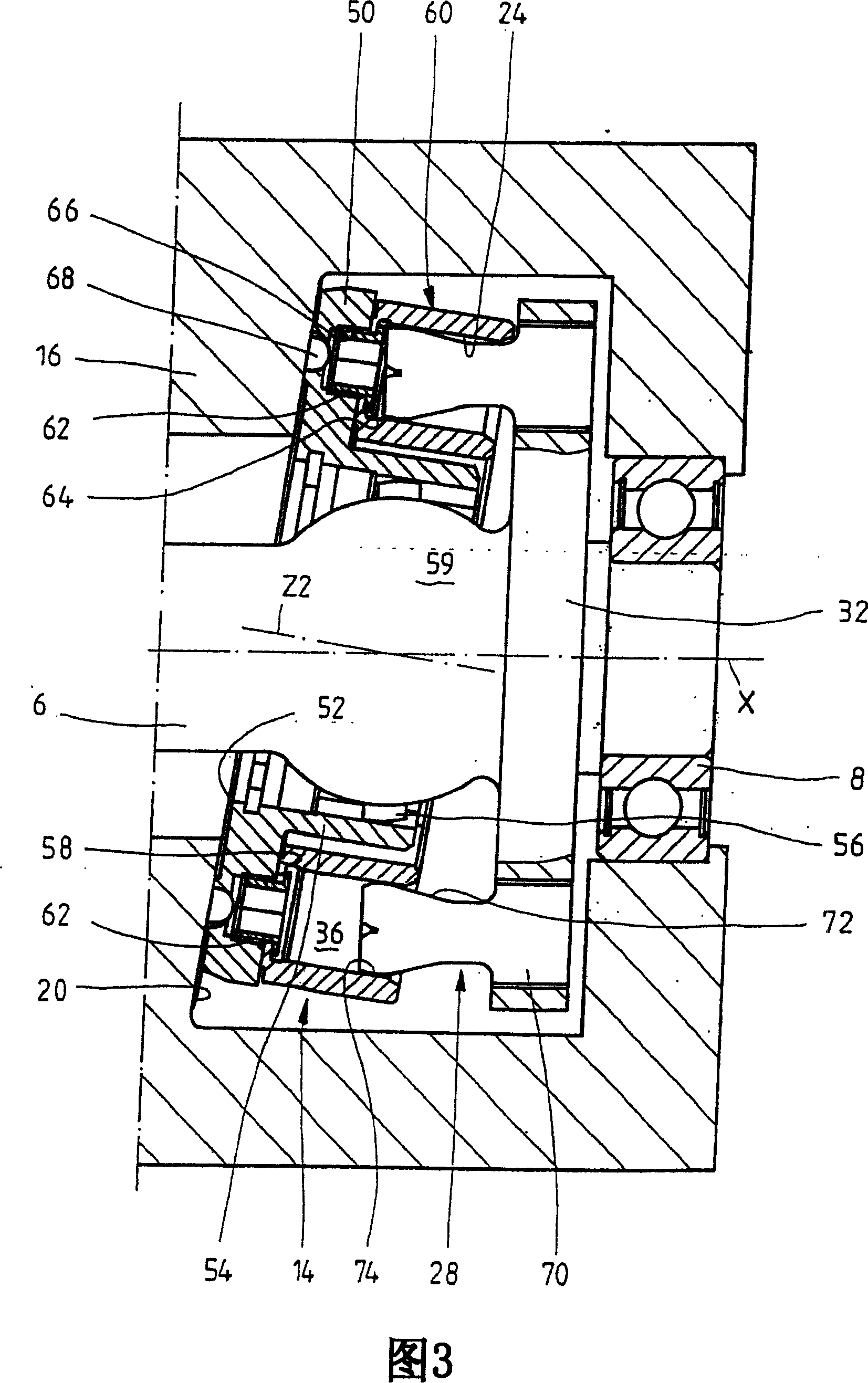

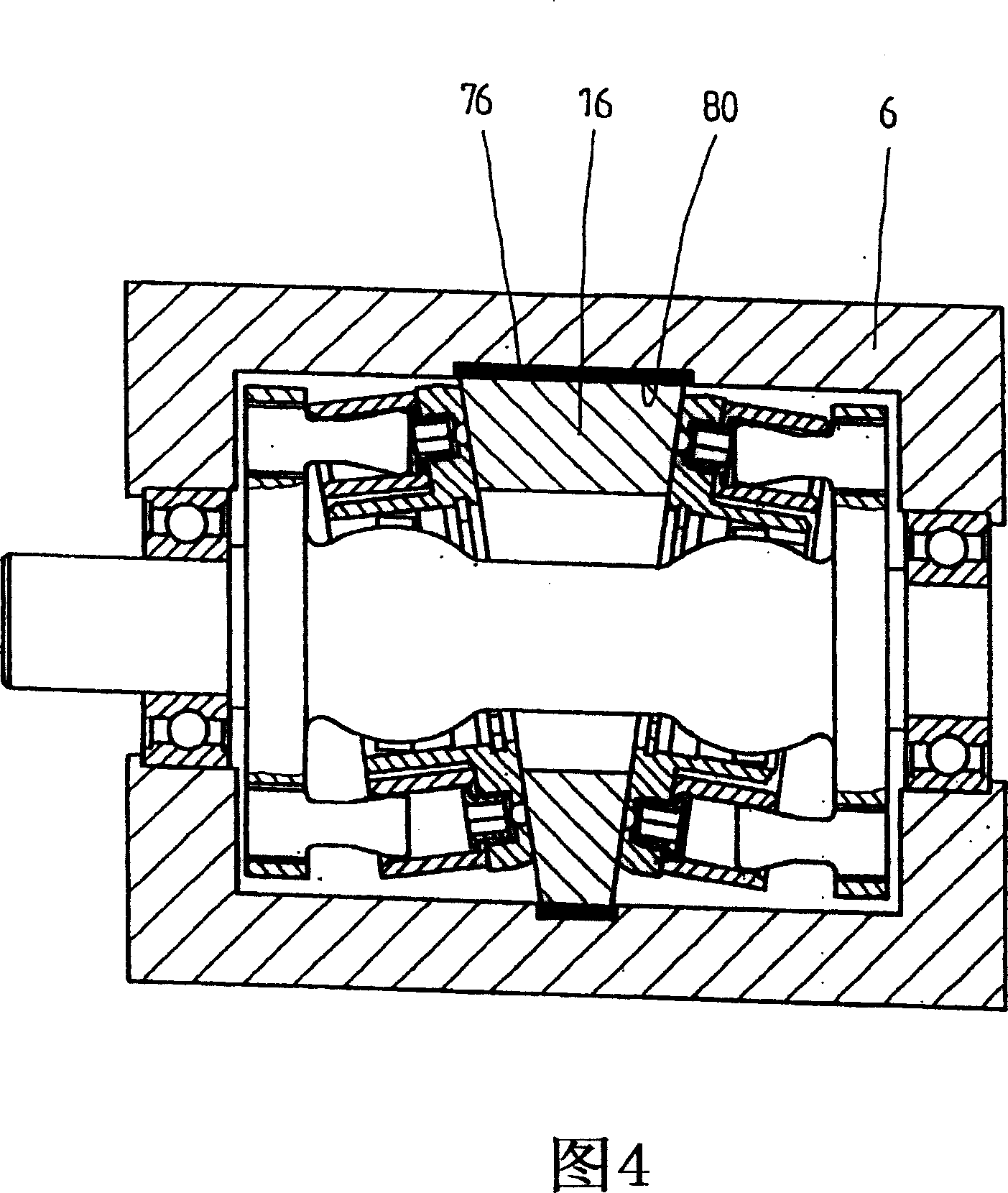

[0019] In FIG. 1 , a simplified longitudinal section through an axial piston machine 1 , such as a hydraulic pump, is shown. FIG. 2 shows a geometrically imprecise schematic cross-section along the vertical dotted line y in FIG. 1 . The axial piston machine 1 thus has a housing 2 in which an axial bore 4 is formed. In this shaft bore, the shaft 6 is supported by two bearings 8 , 10 . Said shaft 6 (drive shaft in the case of the pump) supports two cylinder barrels 12 , 14 , the axes of rotation Z1 and Z2 of which are inclined with respect to the axis X of rotation of shaft 6 .

[0020] The two cylinder barrels 12 , 14 , which are inclined to one another, are supported on a control disk 16 accommodated in the housing 2 at the center (viewed according to FIG. 1 ). The end face of the control disk 16 is formed by two inclined surfaces 18 , 20 . According to FIG. 1 , these inclined surfaces 18 , 20 are mutually inclined in such a way that the control disk 16 tapers downwards fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com