Panel unloading and loading hig slicing filling mining method

A filling mining method and filling mining technology, applied in the direction of filling, ground mining, mining equipment, etc., can solve the inability to implement large-scale stope structure and large-scale mechanized mining operations, stope production capacity and mining efficiency constraints, stope Roof collapse and other problems, to achieve the effect of realizing large-scale mechanized mining operations, expanding the size of the stope structure, and improving the bearing capacity of the rock mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

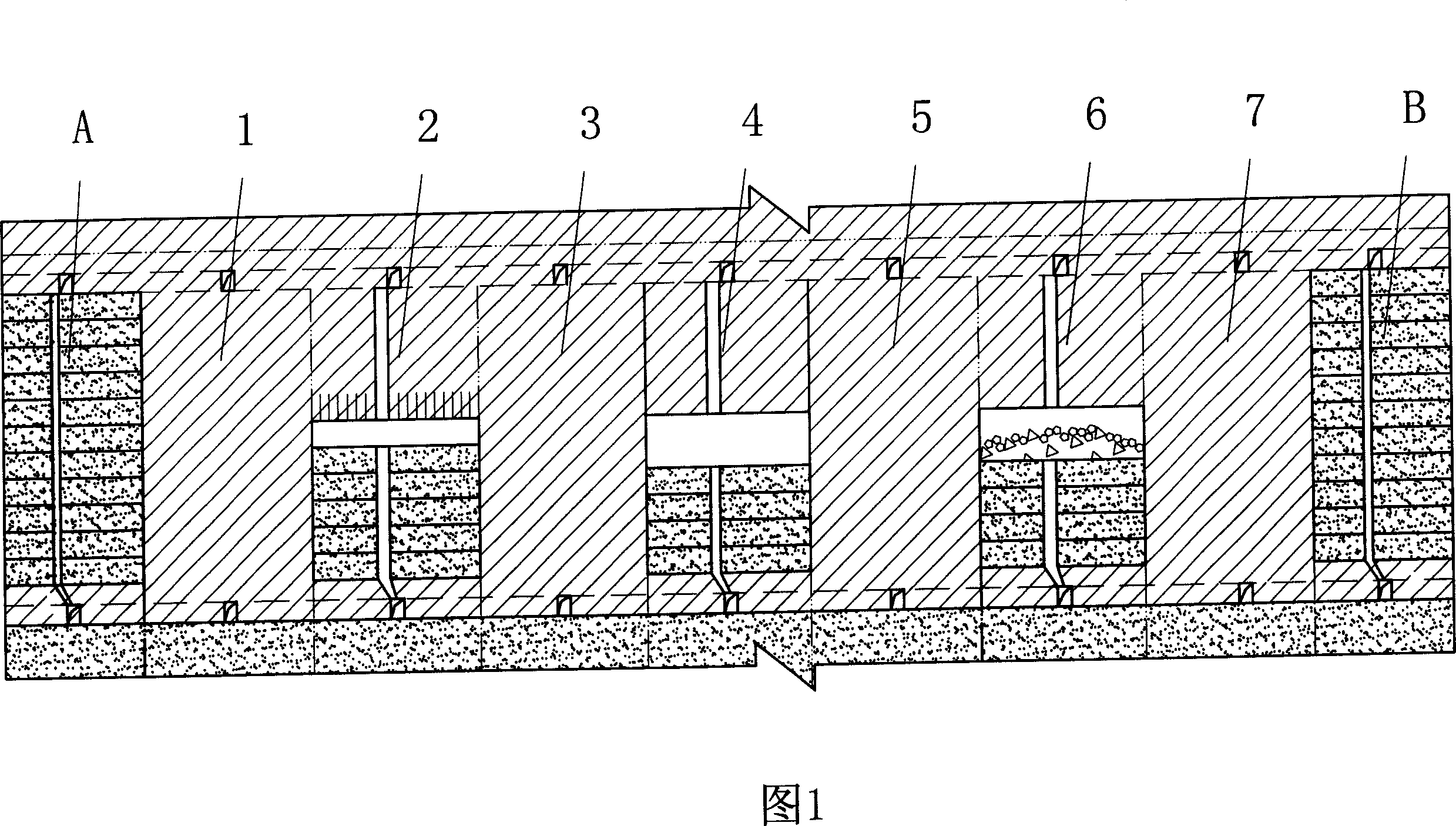

[0009] This is a high layer and fill mining method using only panel end unloading, which divides the ore body into mining panels along the strike direction of the ore body. It can be seen from Fig. 1 that in a mining panel, a vertical ore body trend vertical stope (A, B) is arranged at both ends, and multiple vertical ore body trends are arranged between the vertical stopes A and B Panel stopes (1-7). Vertical slot stopes (A, B) and panel stopes (1-7) are mined by upward layered filling mining method, and tailing sand cemented filling is carried out after mining. However, the vertical slot stope (A, B) must be recovered and filled ahead of the panel stope (1-7). The stope is mined and filled, and the layer height of the vertical groove stope is preferably lower than that of the panel stope, and the width of the vertical groove stope is narrower than the width of the panel stope. In this embodiment, the layer height of the stope of the vertical slot is 2-3m, and the width is ...

Embodiment approach 2

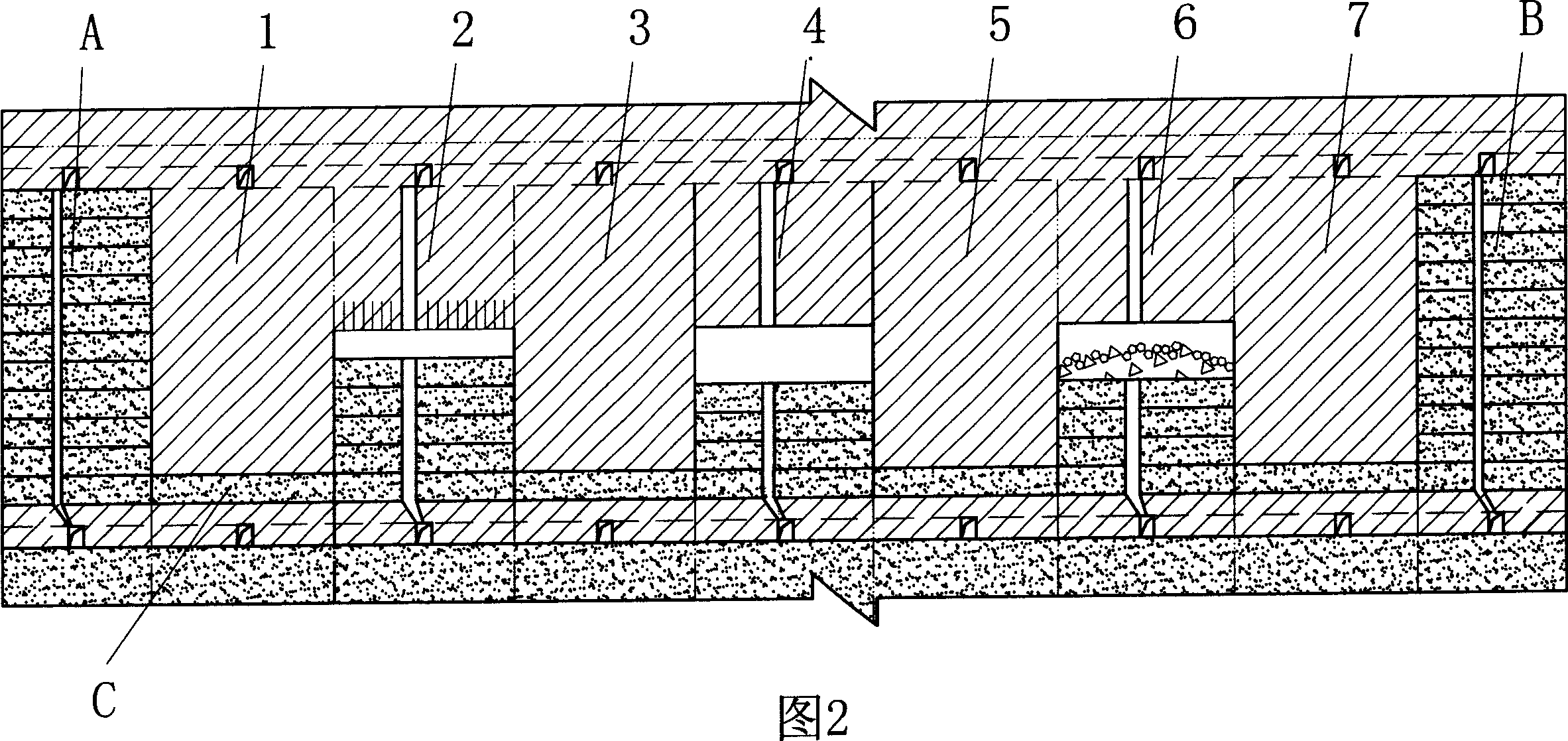

[0011] This is a high-layer filling mining method of unloading at the bottom and end of the panel. The ore body is divided into mining panels along the strike direction, and the bottom stope C is arranged at the bottom of the mining panel, and the two ends of the panel are respectively arranged. Vertical channel stopes (A, B) vertical to the ore body, and a plurality of panel stopes (1-7) vertical to the vertical ore body are arranged between the vertical channel stopes. It can be seen from Figure 2 that this arrangement is different from Embodiment 1, and it can be seen that in this embodiment, the bottom stope C at the bottom of the mining panel is firstly mined by the comprehensive method, and the tailings are cemented after mining filling. The mining and filling operations of vertical slot stopes (A, B) and panel stopes (1-7) are the same as those in Embodiment 1, and will not be described again. In this embodiment, the bottom stope and the vertical groove stope are mined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com