Flexible photosensitive resin plate and preparing method thereof

A photosensitive resin and flexible technology, applied in the field of photosensitive resin plate and its preparation, can solve the problems of insufficient sharpness of dot reduction and small exposure latitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

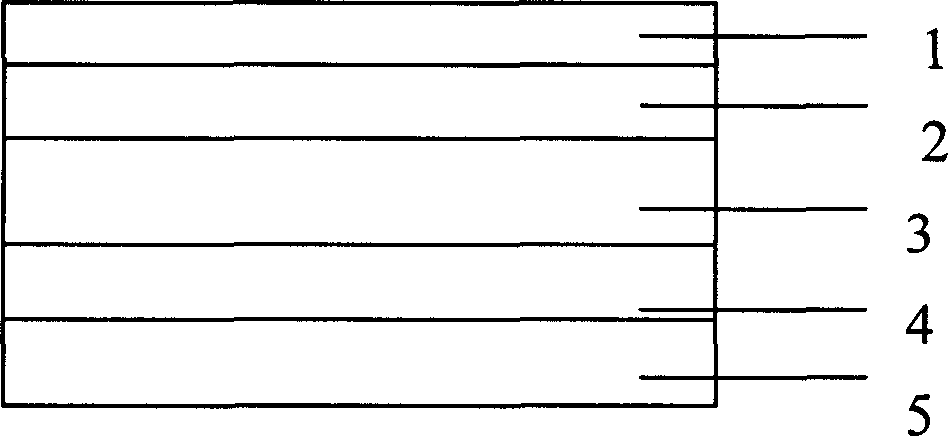

[0027] The invention comprises a support (5), a photosensitive elastomer (3) and a protective film (1), an adhesive layer (4) is arranged between the support (5) and the photosensitive elastomer (3), and the photosensitive elastomer (3) A layer of anti-adhesive layer (2) is compounded on the top, and the anti-adhesive layer (2) contains dye, and the maximum absorption wavelength of the dye is 450nm. As a preferred solution, the dye is a red dye or a mixture of red dyes. The weight ratio of the dye to the total solids of the release layer material is 0.01%.

[0028] The preparation method of the flexible photosensitive resin plate is to compound one or more anti-adhesive layers containing 0.01% dye on the photosensitive elastomer that has been kneaded at a temperature of 20 ° C and a pressure of 0.15 MPa, and then remove the protective film. Expose, make a plate, and get a flexible photosensitive resin plate. The dye is preferably a red dye or a mixture of red dyes. Or, as a...

Embodiment 2

[0030] The invention comprises a support (5), a photosensitive elastomer (3) and a protective film (1), an adhesive layer (4) is arranged between the support (5) and the photosensitive elastomer (3), and the photosensitive elastomer (3) Two anti-adhesive layers (2) are compounded on it, and at least one anti-adhesive layer (2) contains a dye, and the maximum absorption wavelength of the dye is 750nm. The dye is a red dye or a mixture of red dyes. The dye should use Neozapon Red 335 or Red Base 543 or Zapon Red 335 / 395 or Neozapon Red 395 or Neozapon One of Red 346 or Valifast Red 3306 or Valifast Red 3320 or their mixture. The amount of the dyestuff is 3% by weight of the total solids of the release layer material.

[0031] The preparation method of the flexible photosensitive resin plate in the present invention: on the photosensitive elastomer that has been kneaded, at a temperature of 130 ° C and a pressure of 14 MPa, one or more anti-adhesive layers containing 3%...

Embodiment 3

[0033] The invention comprises a support (5), a photosensitive elastomer (3) and a protective film (1), an adhesive layer (4) is arranged between the support (5) and the photosensitive elastomer (3), and the photosensitive elastomer (3) Three anti-adhesive layers (2) are compounded on it, and at least one anti-adhesive layer (2) contains a dye, and the maximum absorption wavelength of the dye is 517nm. As a preferred solution, the dye is a red dye or a mixture of red dyes. The dye should use Neozapon Red 335 or Red Base 543 or Zapon Red 335 / 395 or Neozapon Red 395 or Neozapon One of Red 346 or Valifast Red 3306 or Valifast Red 3320 or their mixture. The weight ratio of the dye to the total solids of the release layer material is 1.5%.

[0034] The preparation method of the flexible photosensitive resin plate of the present invention: on the photosensitive elastomer that has been kneaded, at a temperature of 50 ° C and a pressure of 12 MPa, compound one or more anti-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com