Pocket mouth pipe edges sewing machine

A sewing machine and hemming technology, which is applied to sewing machine components, program-controlled sewing machines, sewing machine control devices, etc., can solve the problem of not being able to form the cutting seam of the center cutter correctly, and achieve the effect of improving the correctness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] (The overall structure of the embodiment of the invention)

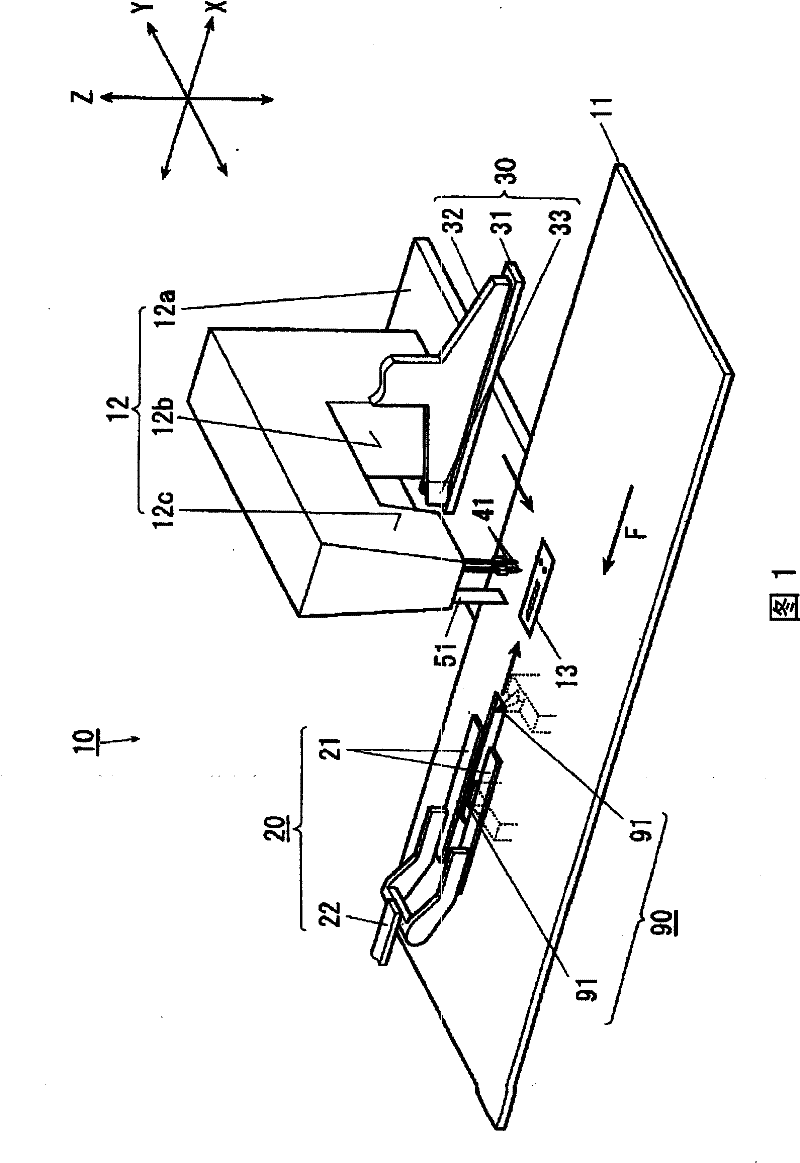

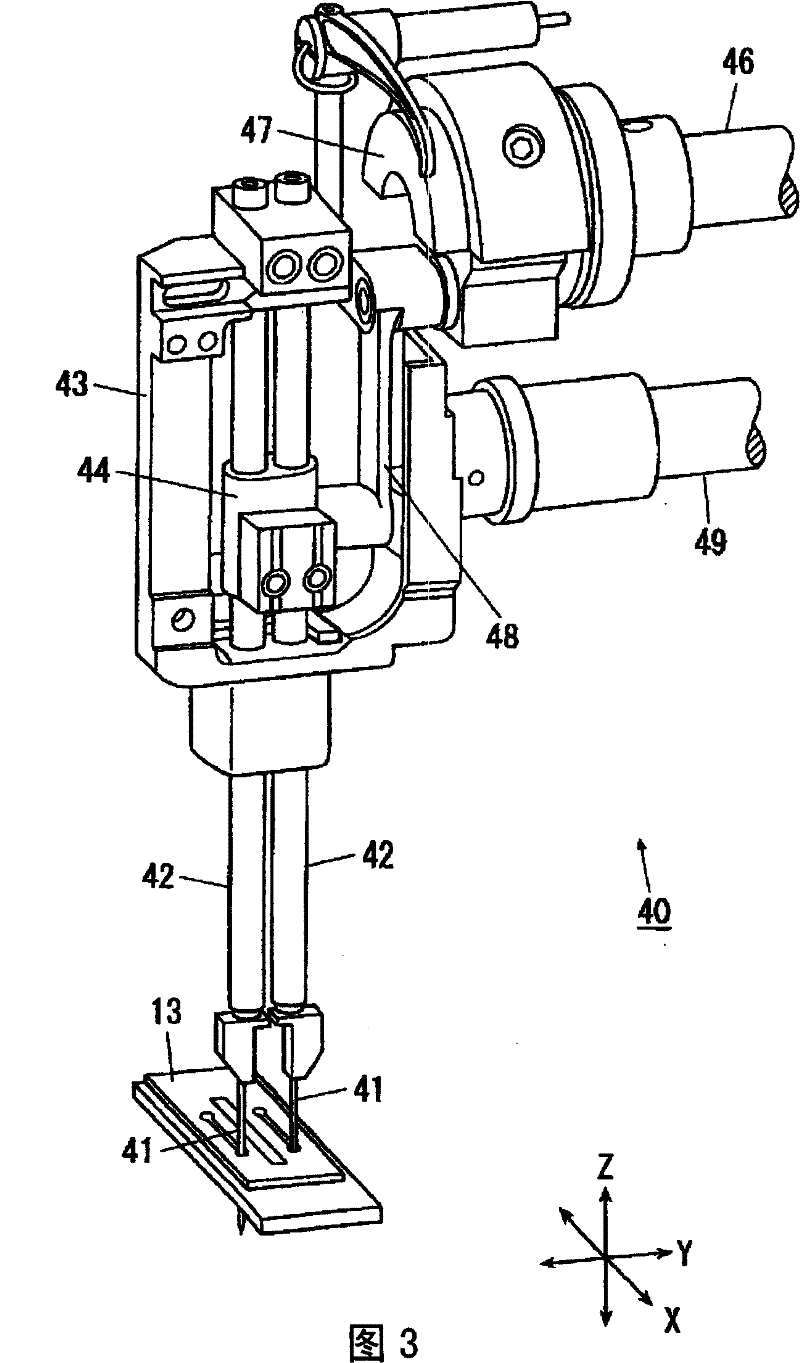

[0050] Below, refer to Figure 1~Figure 17 The bag hemming sewing machine 10 according to the embodiment of the present invention will be described. figure 1 It is a perspective view showing a schematic structure of the entire bag-mouth piping sewing machine 10. In addition, in this embodiment, each direction is determined on the basis of the XYZ axis shown in each figure, and the Z axis direction is consistent with the vertical movement direction of the center cutter described later, and the plane of the sewing industry is the same as the Z axis direction. Perpendicular, the direction in which the cloth is fed parallel to the work plane is referred to as the X-axis direction, and the direction parallel to the work plane and perpendicular to the X-axis direction is referred to as the Y-axis direction.

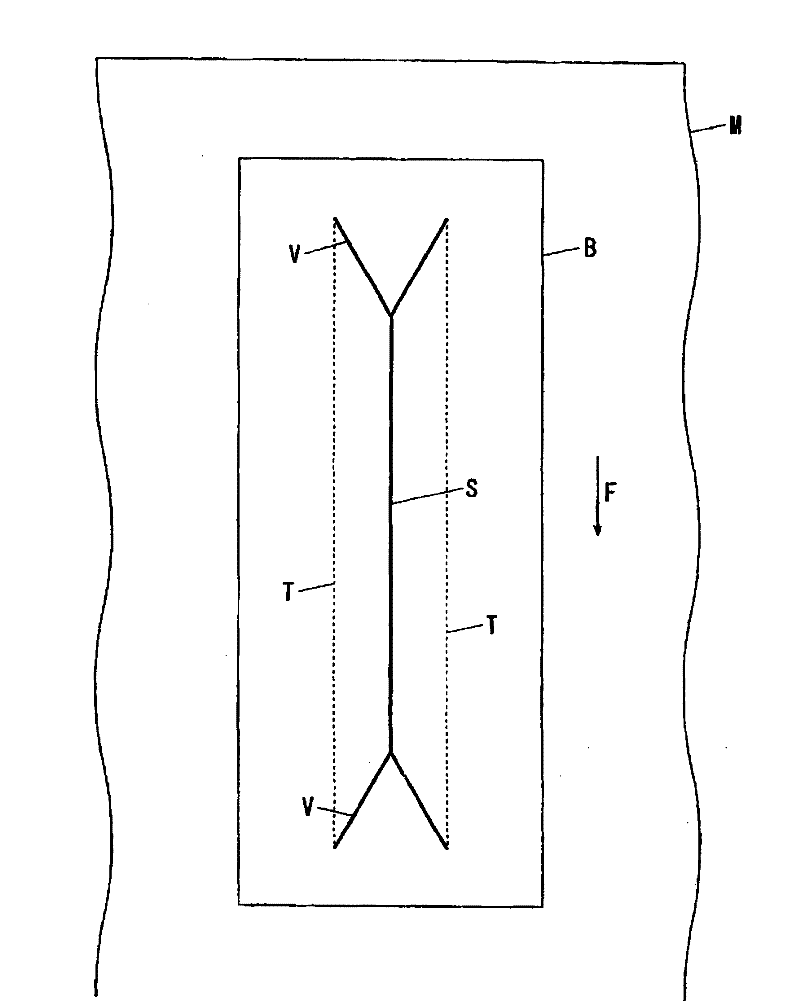

[0051] The bag hemming sewing machine 10 uses two parallel stitches T formed by double needles 41 and 41 to sew ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com