Backhoe

A backhoe, left and right direction technology, applied in the field of backhoe, can solve the problems of short welding length, the two longitudinal ribs are not combined with each other, and it is difficult to improve the installation strength, so as to improve the mutual installation strength and reduce stress concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

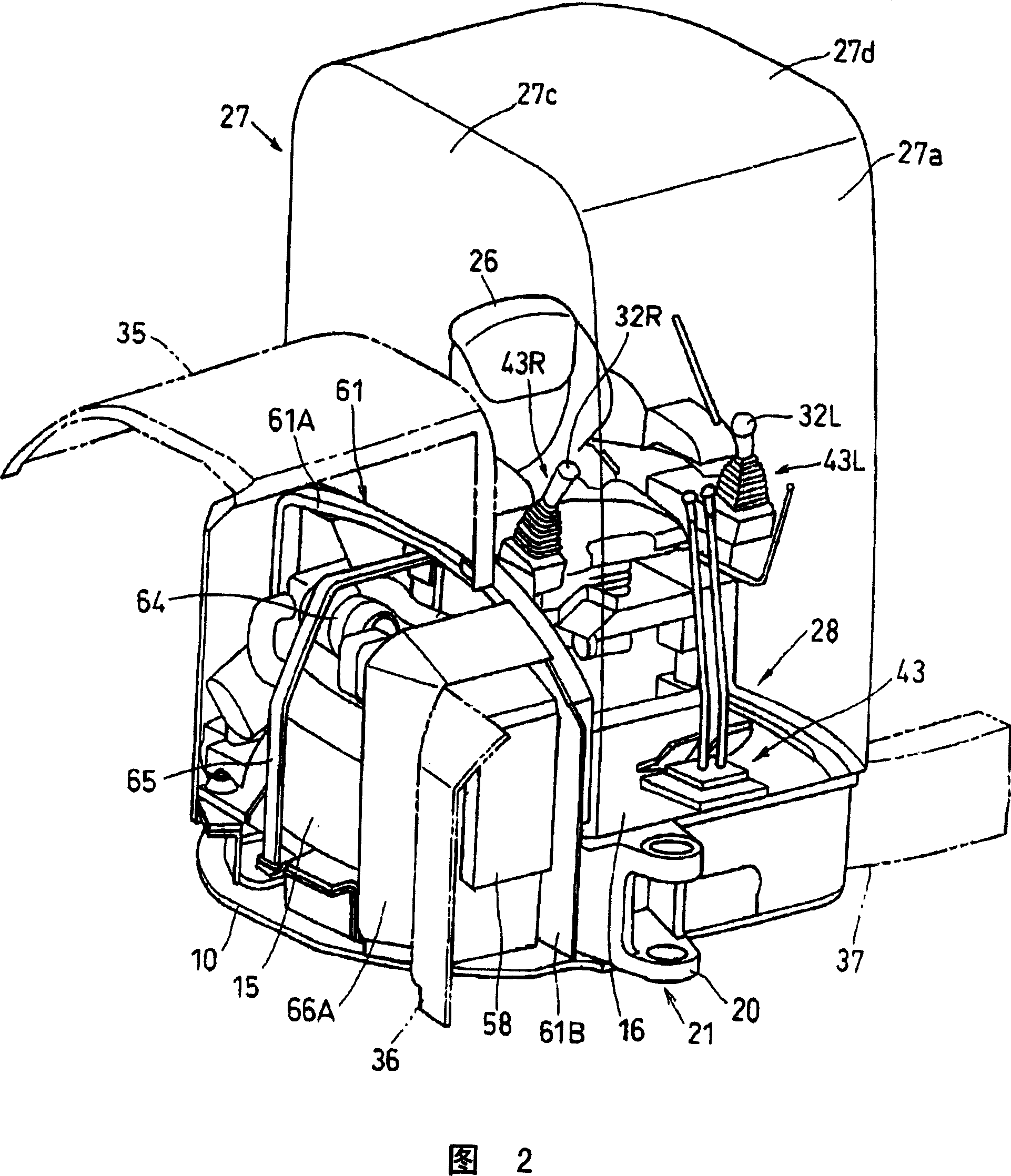

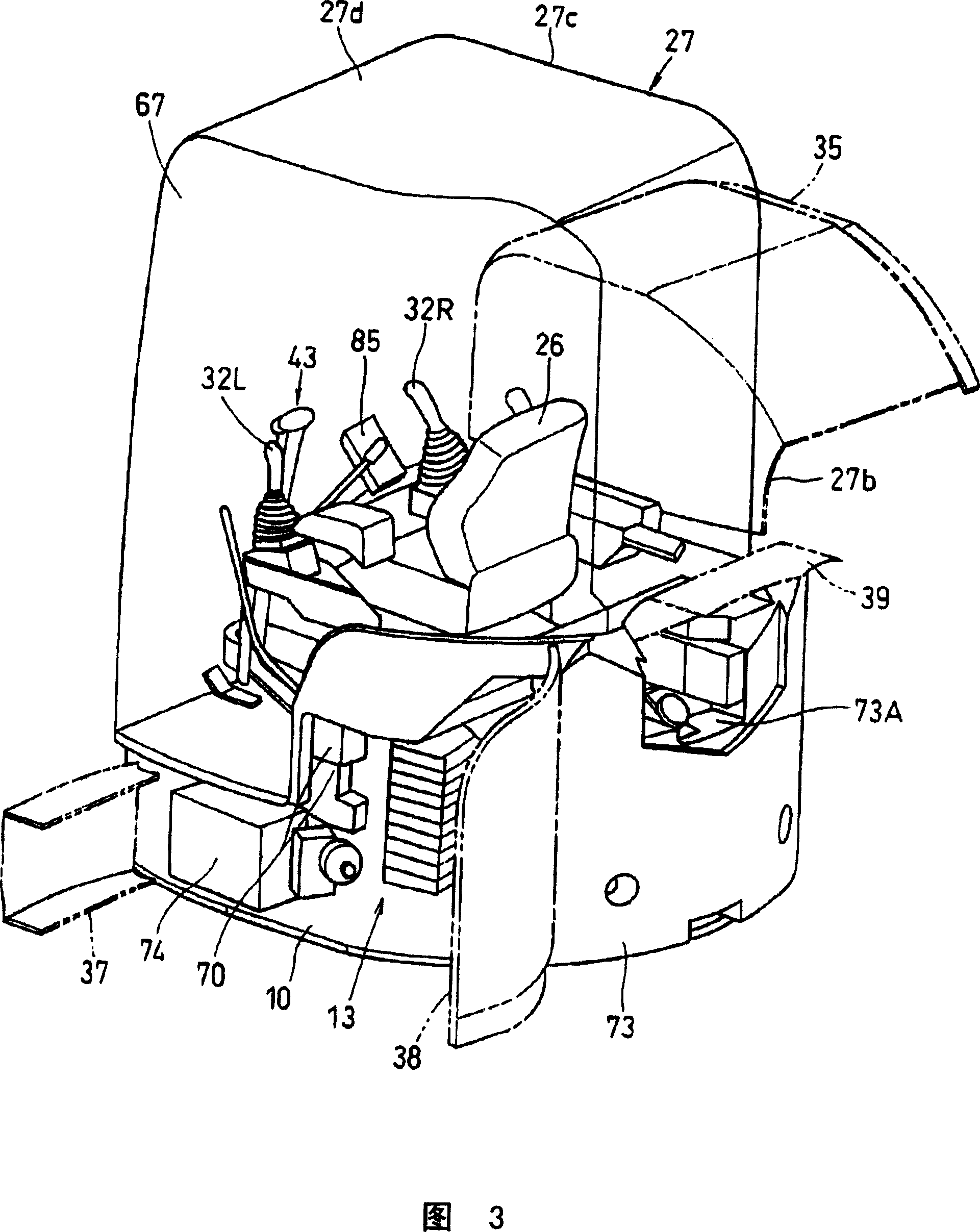

[0038] Embodiments of the present invention will be described below based on the drawings.

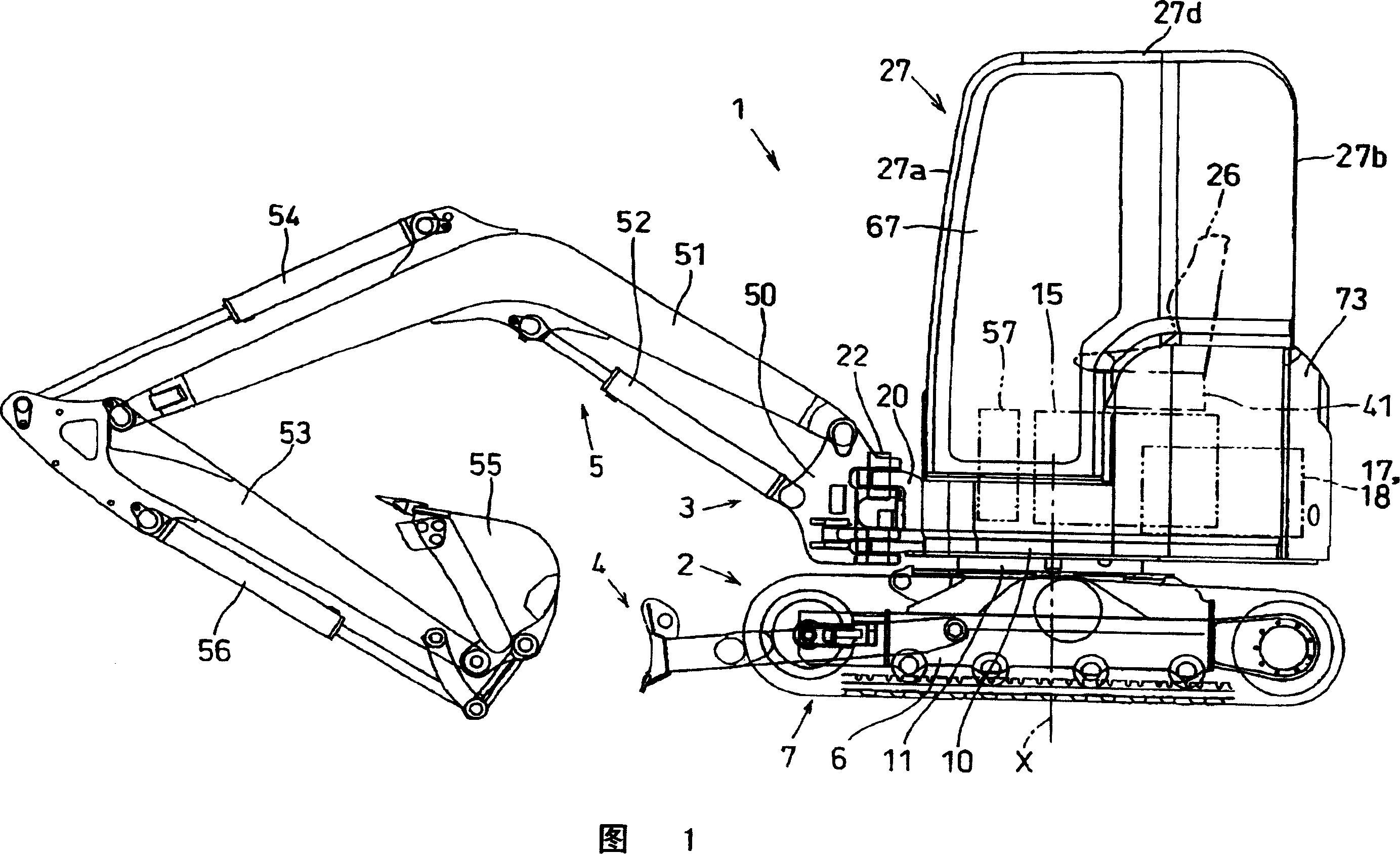

[0039] In Fig. 1~Fig. 14, 1 refers to the backhoe (rotary working machine) of the rear small rotary type, including: the traveling device 2 of the lower part, the superstructure body 3 of the upper part, and the bulldozer installed in the front part of the traveling device 2 ( dozer) device 4, ground working device 5 installed on the superstructure 3.

[0040] The aforementioned traveling device 2 has crawler belt traveling mechanisms 7 on the left and right of a track frame (track frame) 6 and can be driven by a hydraulic motor. A turntable 10 serving as a base of the upper structure 3 is rotatably supported on a track frame 6 about a rotation center (vertical axis) X via a turn bearing 11 and is driven by a turn motor 8 provided on the turntable 10 . The bulldozer 4 is provided with blades on the front portion of the track frame 6 so as to be able to move up and down.

[0041] On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com