Disk driver

A technology of optical disc drive and optical disc, which is applied in the directions of instruments, optical recording/reproduction, head configuration/installation, etc., and can solve the problems that the Z-axis direction cannot be compensated normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

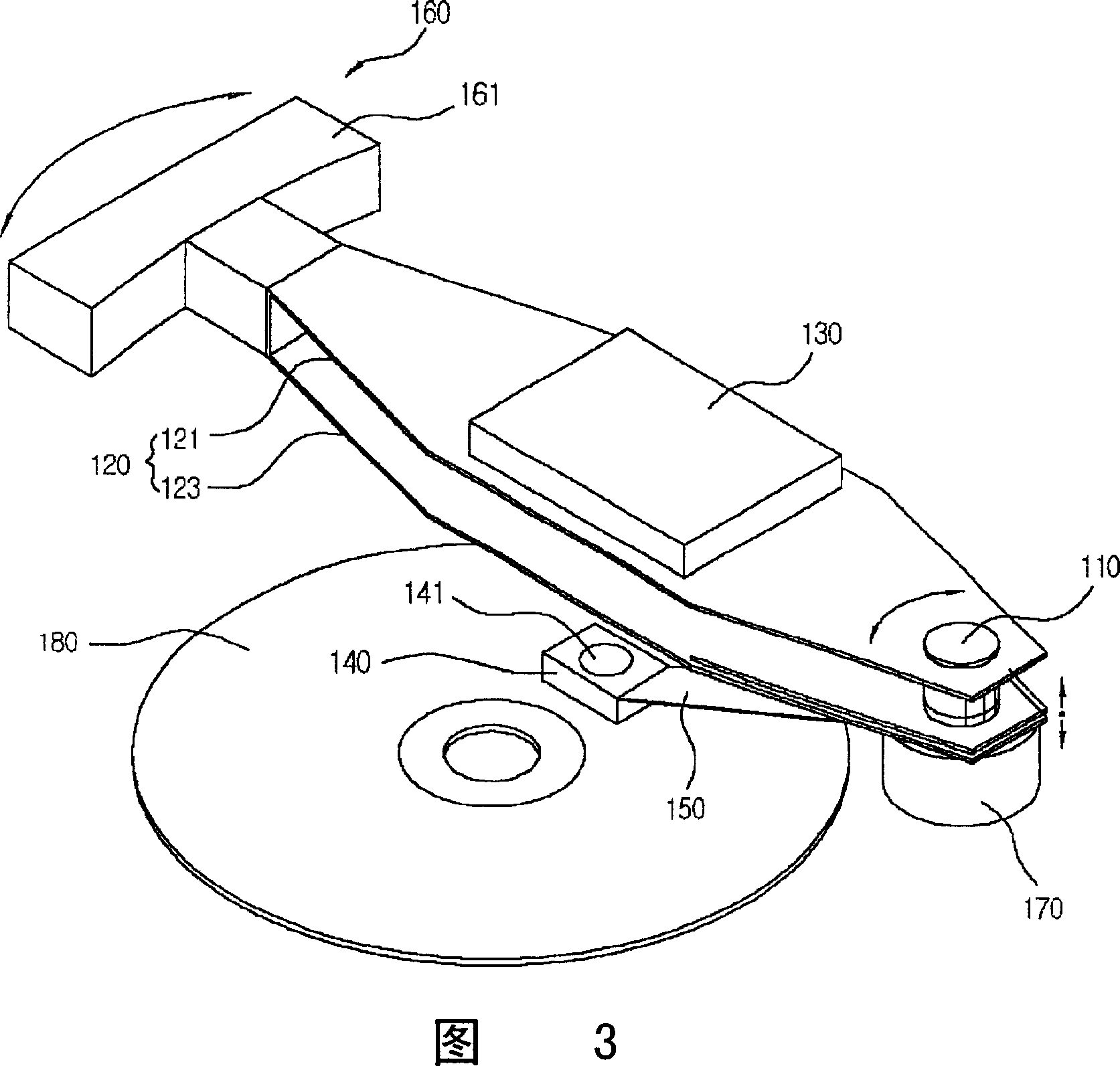

[0040] Embodiments of the optical disc drive of the present invention will be described in detail below with reference to the accompanying drawings.

[0041] FIG. 3 is a perspective view of the optical disc drive of the present invention, and FIG. 4 is a front view of the optical disc drive of the present invention.

[0042] As shown in the figure, the optical disk drive of the present invention includes the following components: a rotating shaft 110, a rocker arm 120, an optical pickup module 130, a guide block 140, a suspension 150, an adjuster 160 for tracking servo, and an adjuster 170 for focus servo .

[0043] The above-mentioned rotating shaft 110 is vertically arranged on a base (not shown), and the rocker arm 120 is combined on the above-mentioned rotating shaft 110 .

[0044] The above-mentioned rocker arm 120 is rotatably coupled to the above-mentioned rotating shaft 110 and adjusted at a certain interval, and is composed of a pair of plates (upper and lower plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com