Wiper installation for the windscreen of a motor vehicle

A technology for automobile glass and automobile side, which is applied in the direction of vehicle cleaning, vehicle maintenance, transportation and packaging, etc. It can solve the problems of doubtful mechanical reliability and high assembly time, and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

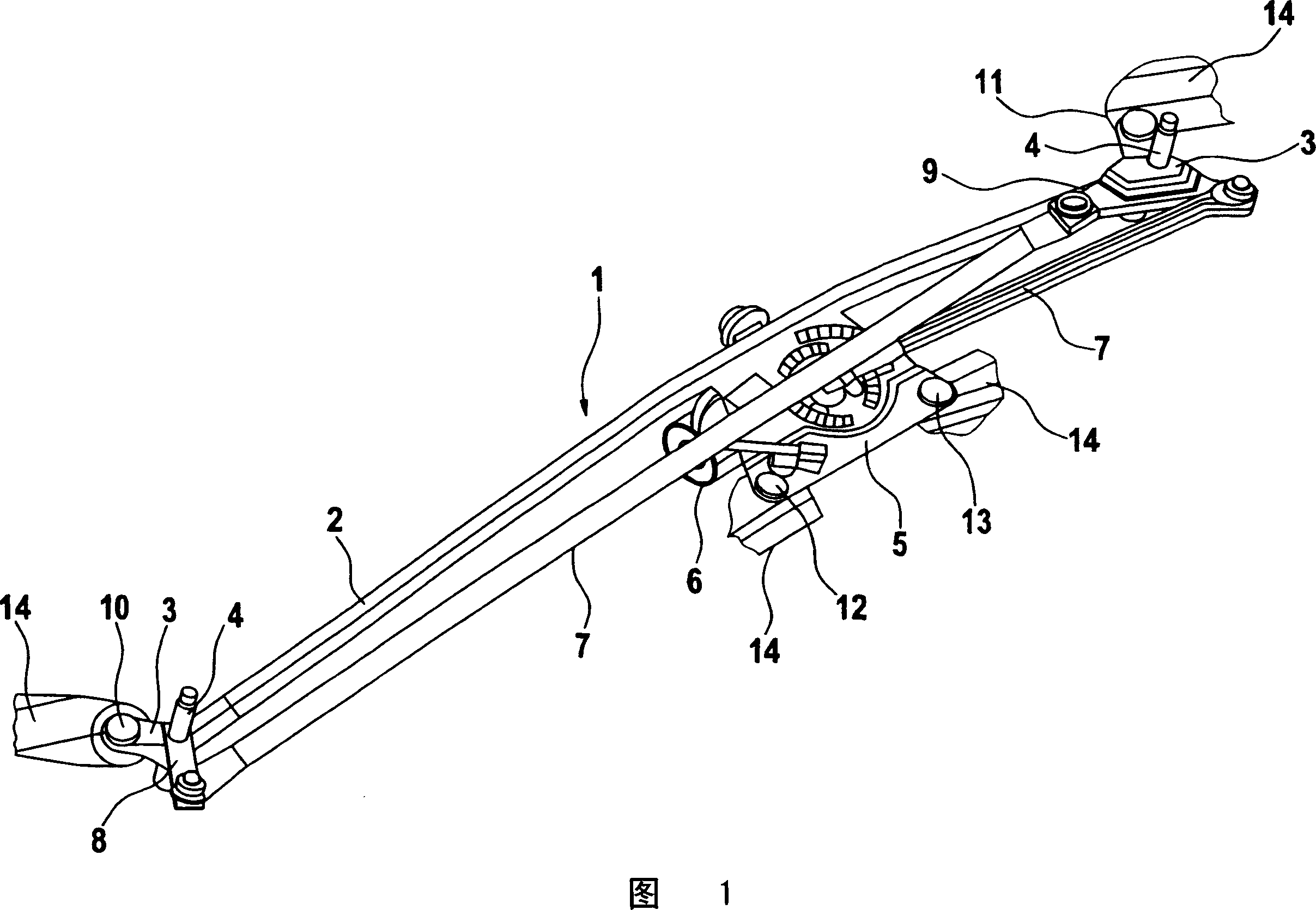

[0020] FIG. 1 shows a glass-to-water device for motor vehicles known from the prior art, which comprises a rod-shaped support body 2 , which is supported at both ends by a bearing body 3 (shaped tube). A wiper shaft 4 for fastening a windshield wiper arm (not shown) is mounted axially fixed and rotatable in each bearing body 3 . Arranged on the support body 2 , approximately on its middle part, namely the plate 5 , is a drive 6 which acts on the connecting rod 7 . The end of the connecting rod 7 is hingedly connected to the swing arm 8 or 9, which is also rigidly connected to the wiper shaft 4 respectively.

[0021] This known windshield wiper device 1 is fastened at points 10 , 11 , 12 and 13 to a motor vehicle body 14 under a windshield (not shown) by means of fastening means. Currently, this fastening is typically achieved at least at one of the points 10 to 13 by means of a screw, while at other points plug pins can be provided on the device side. In other embodiments, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com