New type structured composite profile material unit

A new type of structure and profile technology, applied in the direction of slender components, building components, etc., can solve the problems of mold waste and high mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

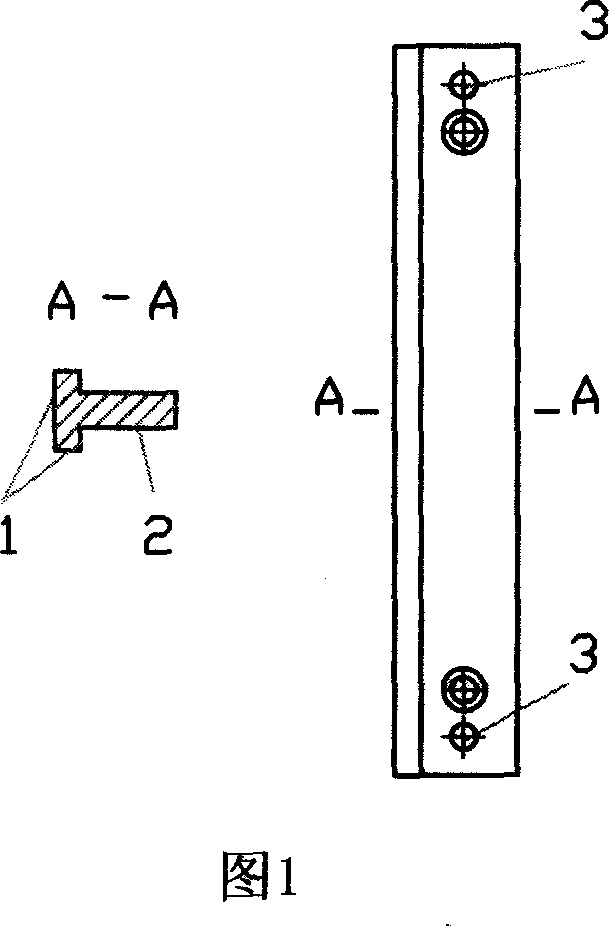

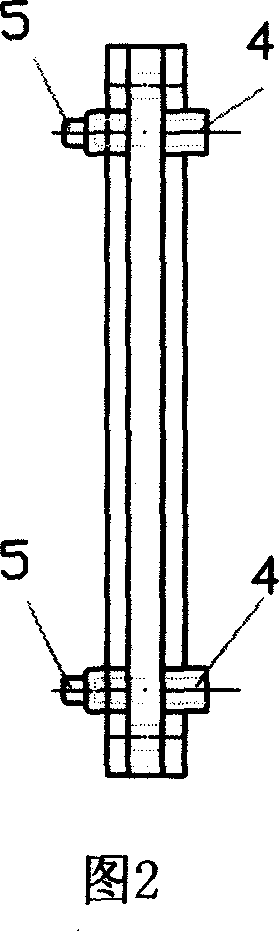

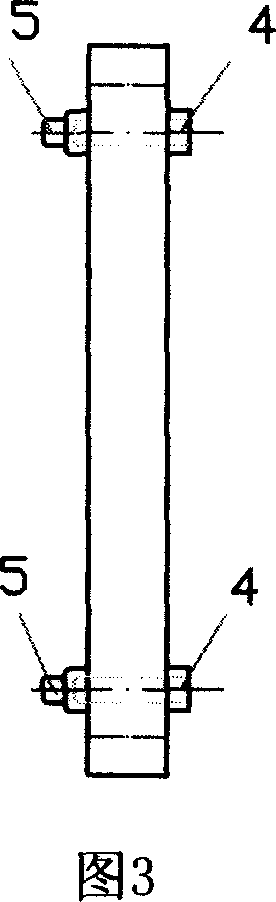

[0025] As shown in Figures 1, 2, and 3, a plastic injection model or a hot-pressing model or a casting model is made. The corresponding convex protrusions or protruding concave grooves on both sides of the vertical wall in the T-shaped section match in size, and can be injection molded, hot-pressed or cast. It becomes a T-shaped straight composite profile unit provided by the present invention.

Embodiment 2

[0027] As shown in Figures 1, 2, 3, and 4, a plastic injection model or a hot-pressing model or a casting model is made, and the corresponding convex protrusions or protruding concave grooves on both sides of the vertical wall in the T-shaped section match in size, and are molded by injection molding or hot pressing or casting. It can become a straight strip-shaped composite profile unit with a T-shaped vertical wall and a concave notch in the cross section provided by the present invention.

Embodiment 3

[0029] As shown in Figures 5 and 6, a plastic injection model or a hot-pressing model or a casting model is made, and the corresponding convex protrusions or protruding concave grooves on both sides of the vertical wall in the T-shaped section match in size, and can be formed by injection molding or hot pressing or casting. The invention provides a straight-strip combined profile unit whose cross-section is a T-shaped cross-sectional transverse wall with slight convexity on the outer surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com