Electronically compensated LCD assembly

一种组件、电压的技术,应用在偏振补偿领域,能够解决不精确延迟补偿、降低高对比度成像器面板生产量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Definition of Terms

[0077] [72] In relation to light polarizing, compensating and retarding layers, films or plates described in this application, the following definitions are given for the terms used throughout this application.

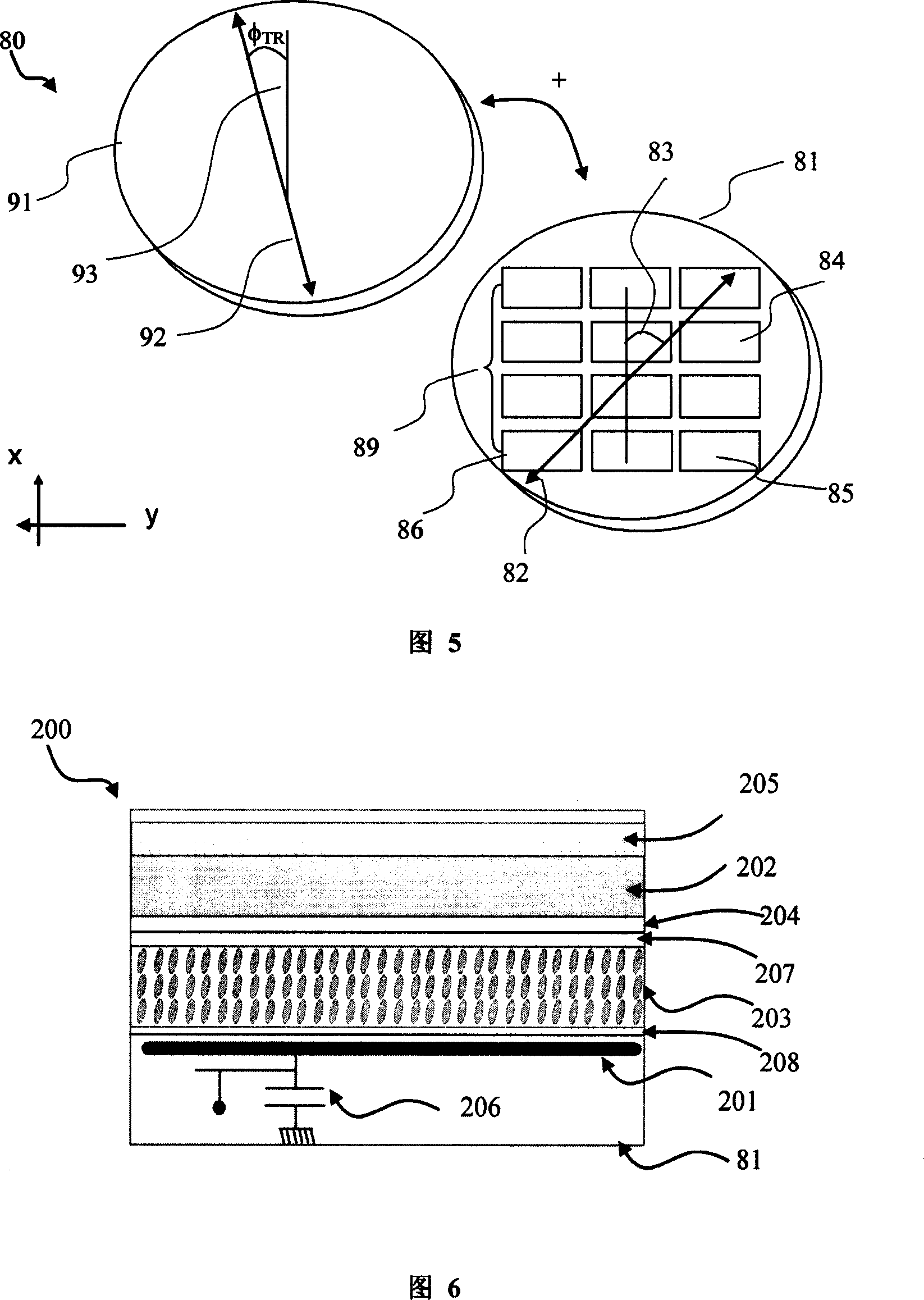

[0078] [73] The term "optical axis", when referring to a birefringent material such as a liquid crystal (LC), is used to denote an axis in the material whereby light rays propagating along the axis are not birefringent. Hereafter in the specification, LC materials used in LCD panels are assumed to be uniaxial and have positive birefringence, i.e. extraordinary refractive index n e is the highest index of refraction for the material where the optical axis coincides with the extraordinary axis.

[0079] [74] The term "slow axis (SA)" as used herein means the projection of the optical axis of a birefringent film (or plate, or layer) onto the plane of the film.

[0080] [75] The term "tilted structure" or "tilted orientation" means that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com