Lightweight permanent embryonic shell in use for filling concrete

A permanent tire and light-weight technology, which is applied to building components, floor slabs, buildings, etc., can solve problems such as difficult compacting and pouring and tamping of cast-in-place concrete, and achieves the effects of low cost, guaranteed pouring quality, and not easy to loosen and fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

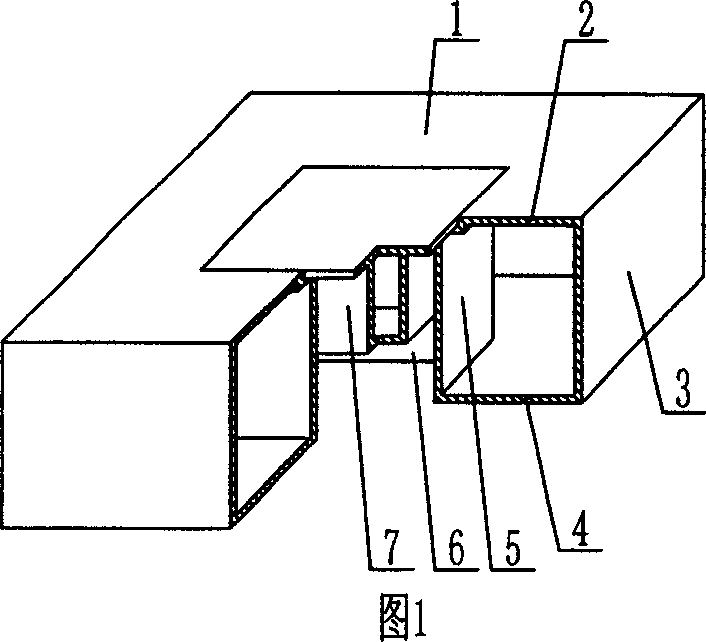

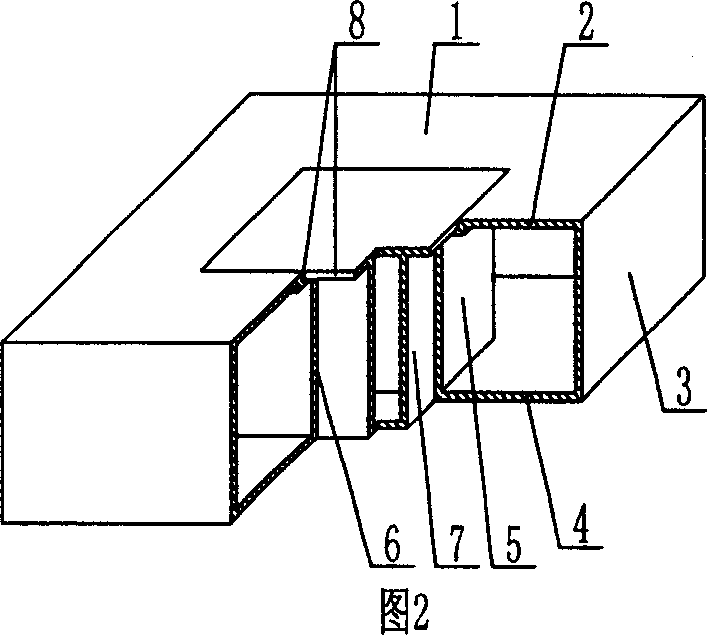

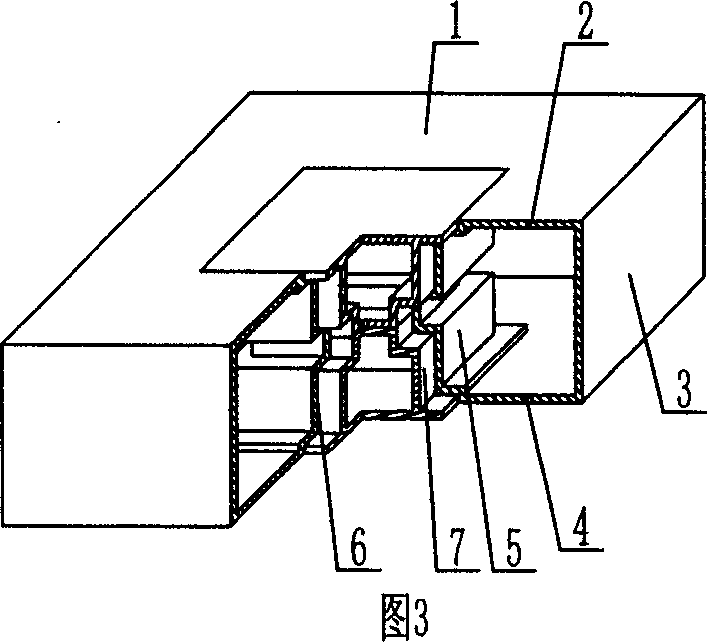

[0104] The present invention will be further described below with reference to the drawings and embodiments.

[0105] As shown in the drawings, the present invention includes a lightweight carcass 1. The lightweight carcass 1 includes an upper shell 2, a surrounding side shell 3, and a lower shell 4. The upper shell 2, the surrounding side shells 3, and the lower shell 4 form a closed space. The cavity is characterized in that it also includes a through-hole tube 5, the through-hole tube 5 is arranged in the closed cavity of the lightweight carcass 1, at least one of the light-weight carcass 1 is formed by the through-hole tube 5 as a through hole The holes 6 for pouring concrete penetrate through the upper and lower shell surfaces of the lightweight carcass 1, and the holes 6 are equipped with hole plugs 17. As shown in Figure 51, the lightweight permanent carcass includes a lightweight carcass 1. The lightweight carcass 1 includes an upper shell 2, a surrounding side shell 3, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com