Liquid trap device for gas

一种捕捉装置、气体的技术,应用在气体用液体捕捉装置领域,能够解决液体捕捉性能低、液体捕捉性能降低、堵塞网眼等问题,达到提高液体捕捉性能、防止局部饱和、延长耐用时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

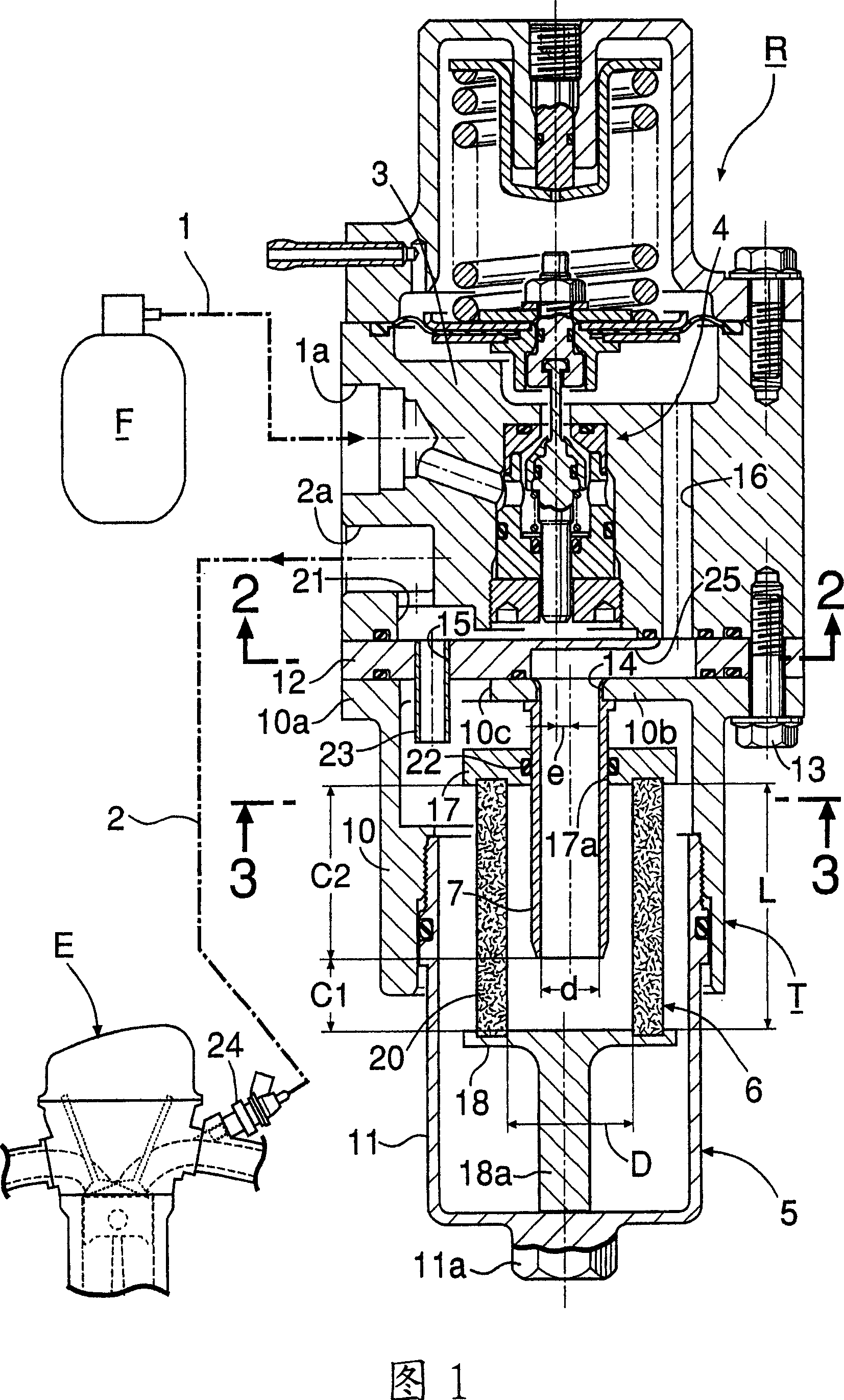

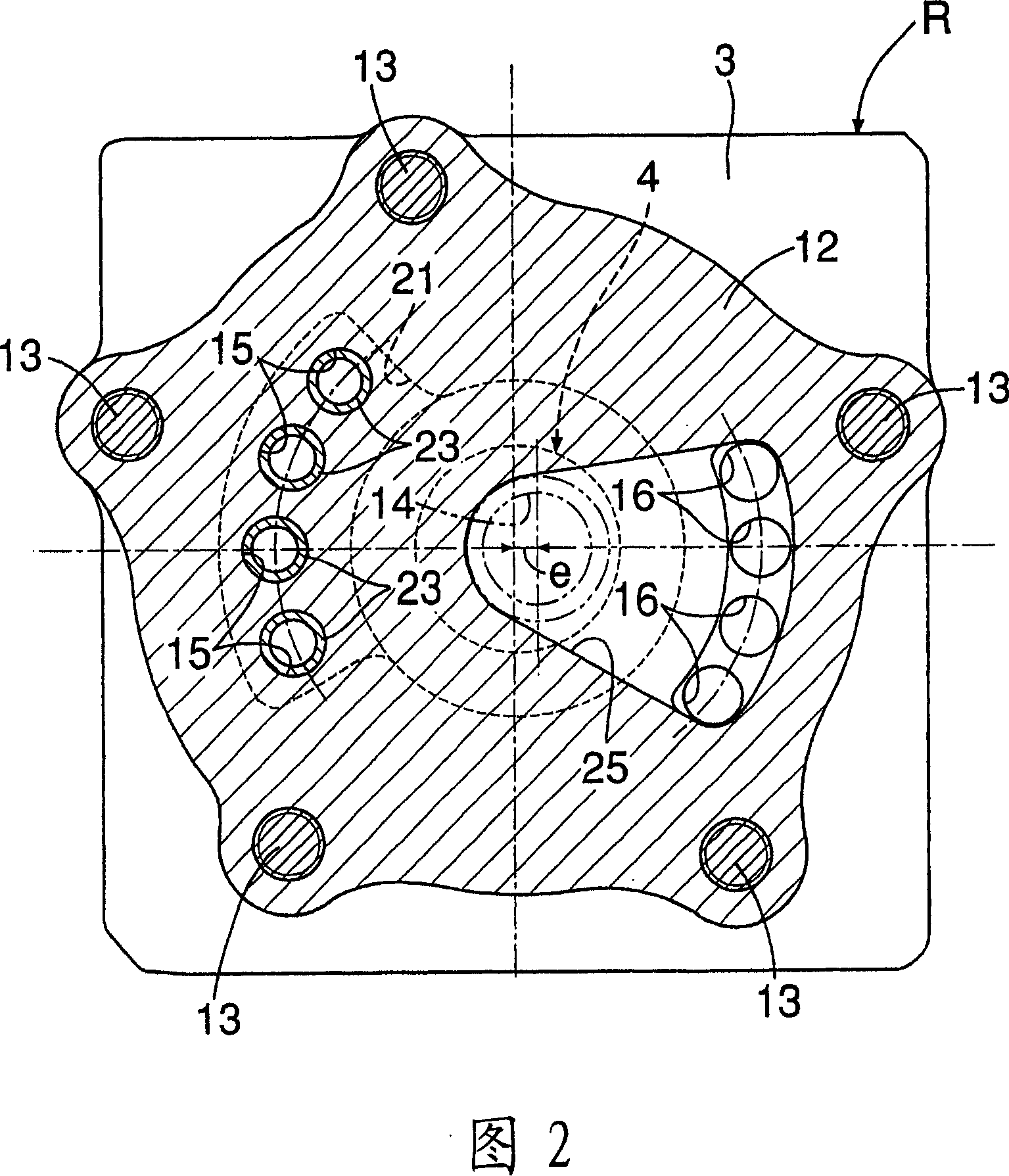

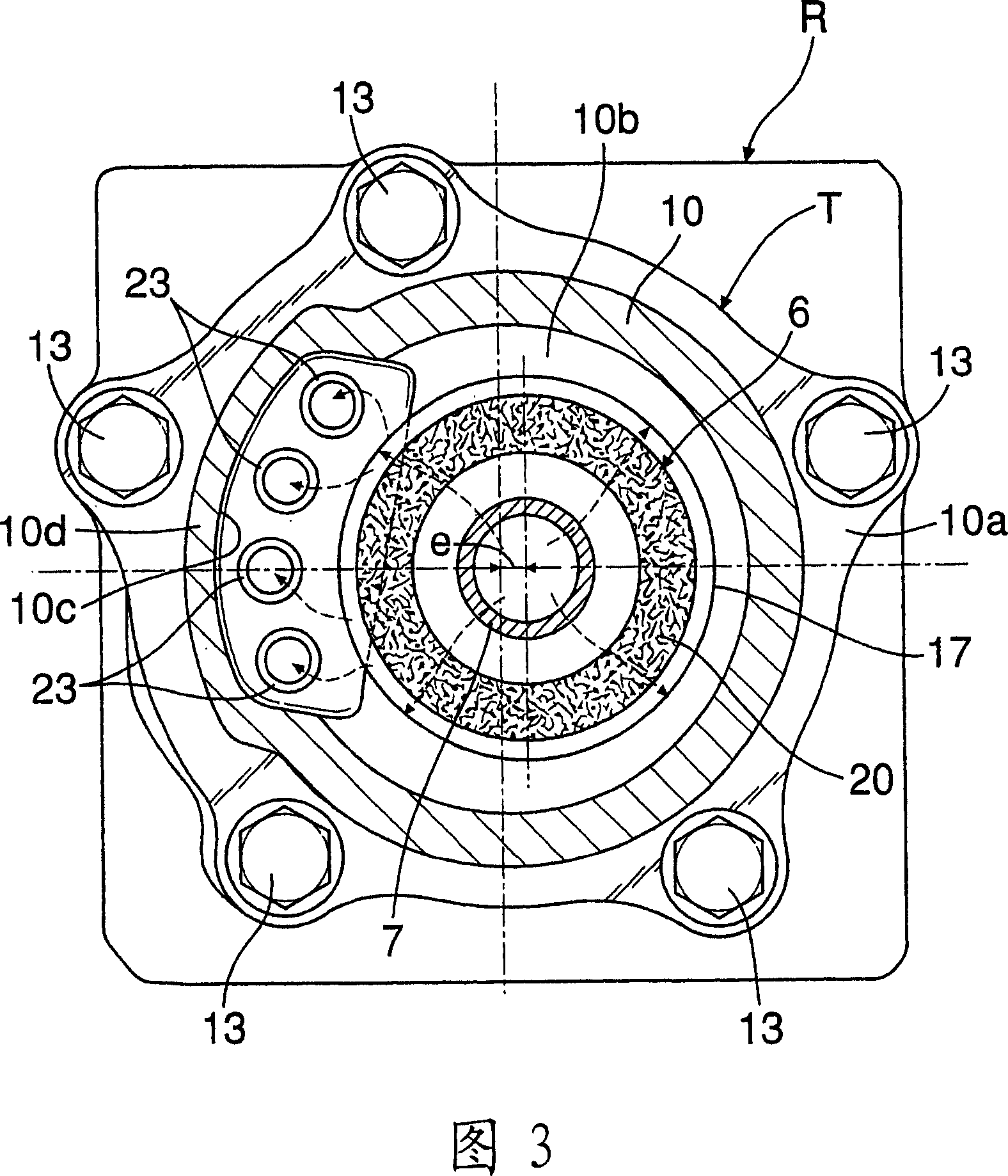

[0028] Embodiments of the present invention will be described below based on preferred embodiments of the present invention shown in the accompanying drawings.

[0029] Fig. 1 is a longitudinal sectional view of a pressure regulator integrally provided with a gas-liquid capturing device according to an embodiment of the present invention, Fig. 2 is a sectional view along line 2-2 in Fig. 1 , and Fig. 3 is a sectional view along line 2 in Fig. 1 3-3 line sectional view, Fig. 4 is a sectional view of four kinds of gas liquid capture devices used as capture performance test samples, and Fig. 5 is a table showing the parameters and capture performance test results of the above four kinds of gas liquid capture devices , FIG. 6 is a graph showing the capture performance test results of the above-mentioned four kinds of gas liquid capture devices.

[0030] First, in FIG. 1, natural gas is compressed and stored in a fuel tank F as a gaseous fuel. When using the high-pressure gas fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com