Silica glass continuous melting oven

A continuous furnace and quartz technology, applied in glass furnace equipment, glass manufacturing equipment, furnaces, etc., can solve problems such as production defects of quartz glass tubes or rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

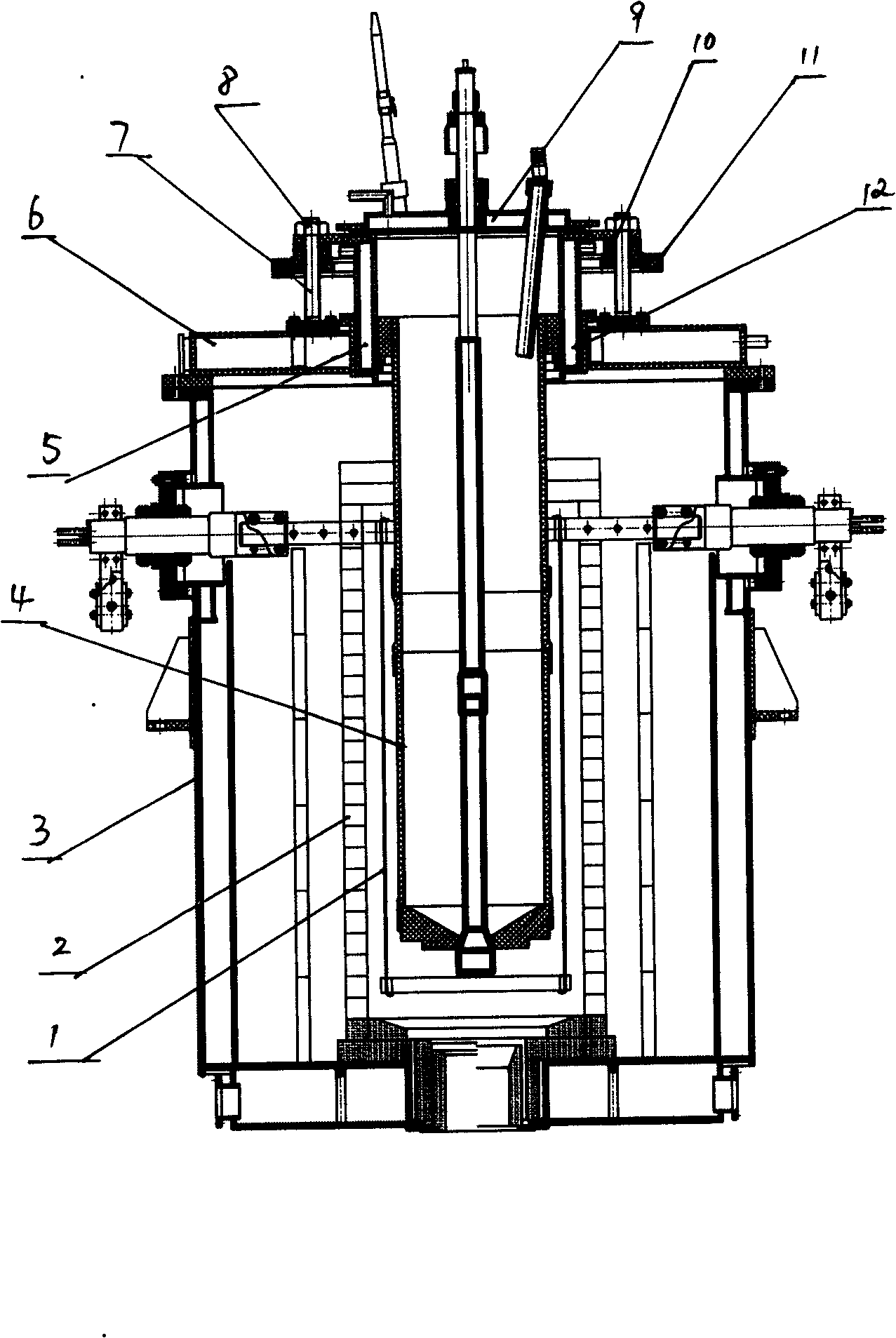

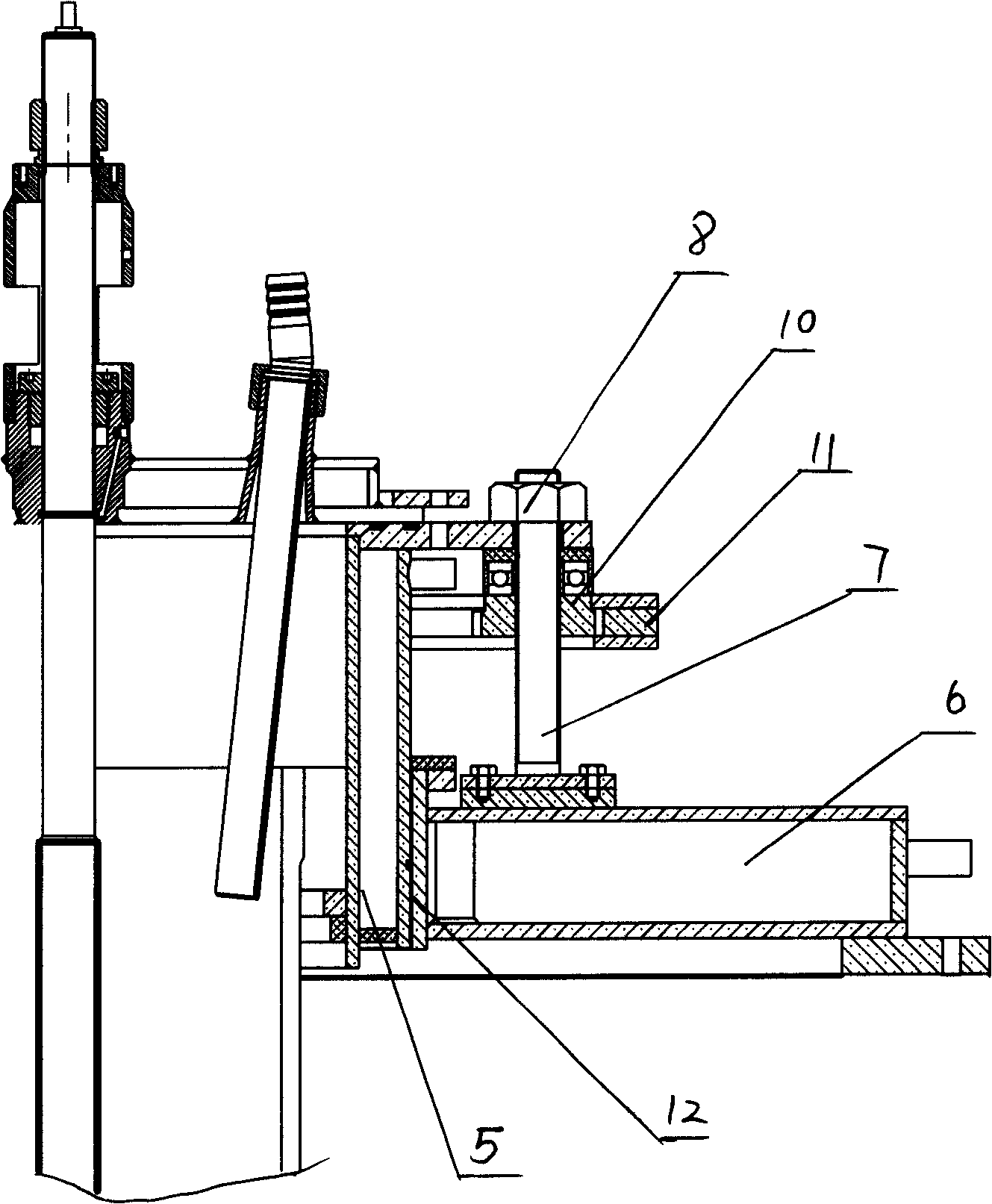

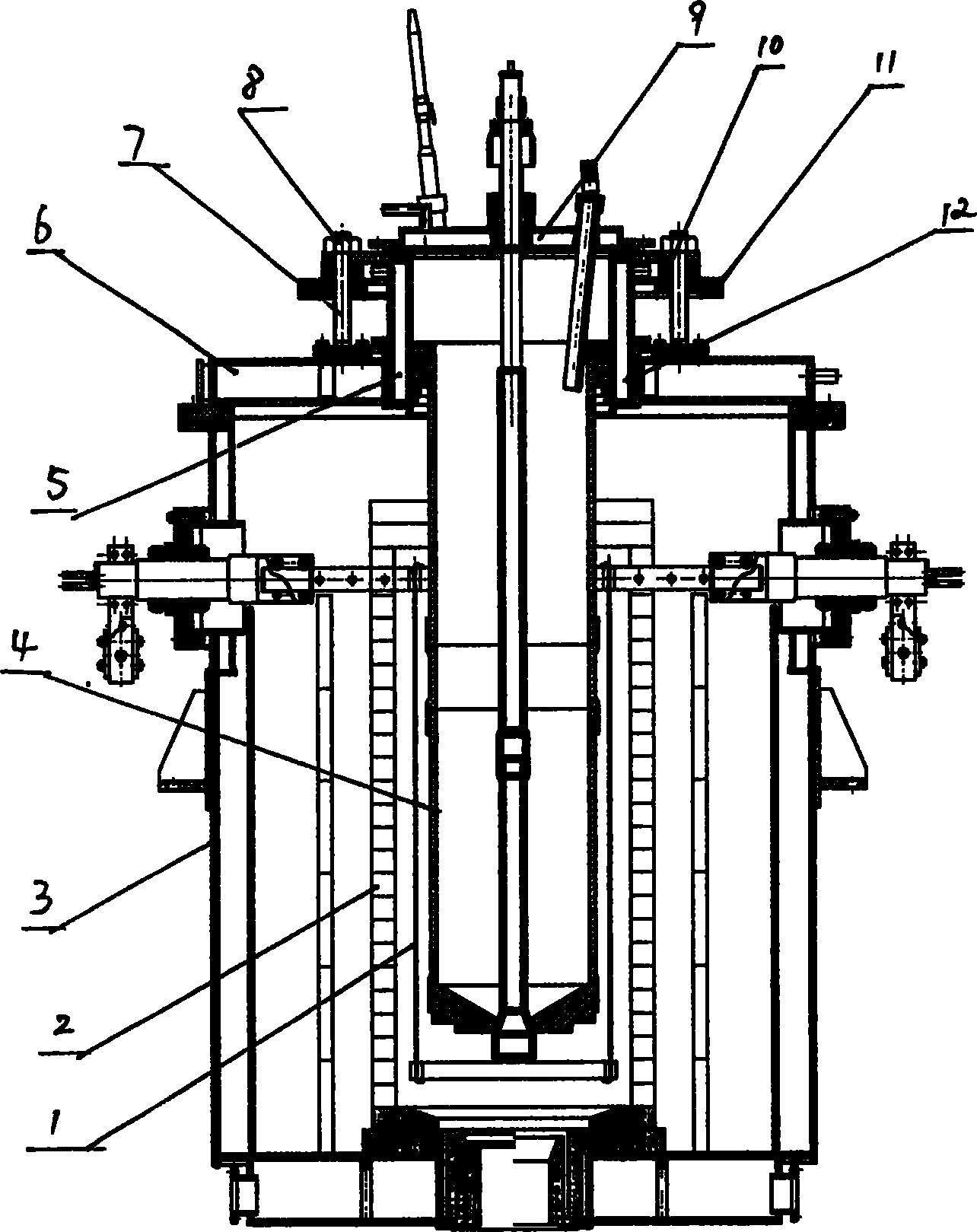

[0010] A quartz continuous melting furnace, which includes a furnace body 3 and a crucible 4 arranged in the furnace body 3, an insulation layer 2 is installed between the crucible 4 and the wall of the furnace body 3, and an insulation layer 2 is installed between the periphery of the crucible 4 and the insulation layer 2 A heating device 1 is provided, the lower part of the crucible 4 is a molding outlet, a core rod is installed in the middle of the crucible 4, an upper cover 6 is installed on the furnace body 3, and a through hole is opened in the middle of the upper cover 6, and the through hole is equipped with A small cover 9, the bottom of the small cover 9 is provided with a boss 5 slidingly fitted with the through hole, a sealing ring 12 is arranged between the outer edge of the boss 5 and the through hole, the upper mouth of the crucible 4 and the boss 5 of the small cover 6 Fixedly connected, a lifting device is housed between the small cover 9 and the loam cake 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com