A kind of laser ultrasonic technology assisted pulse laser drilling device and method

An auxiliary pulse and laser drilling technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of large thermal influence, recasting layer thickness, etc., to improve efficiency, uniform range, and improve drilling quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

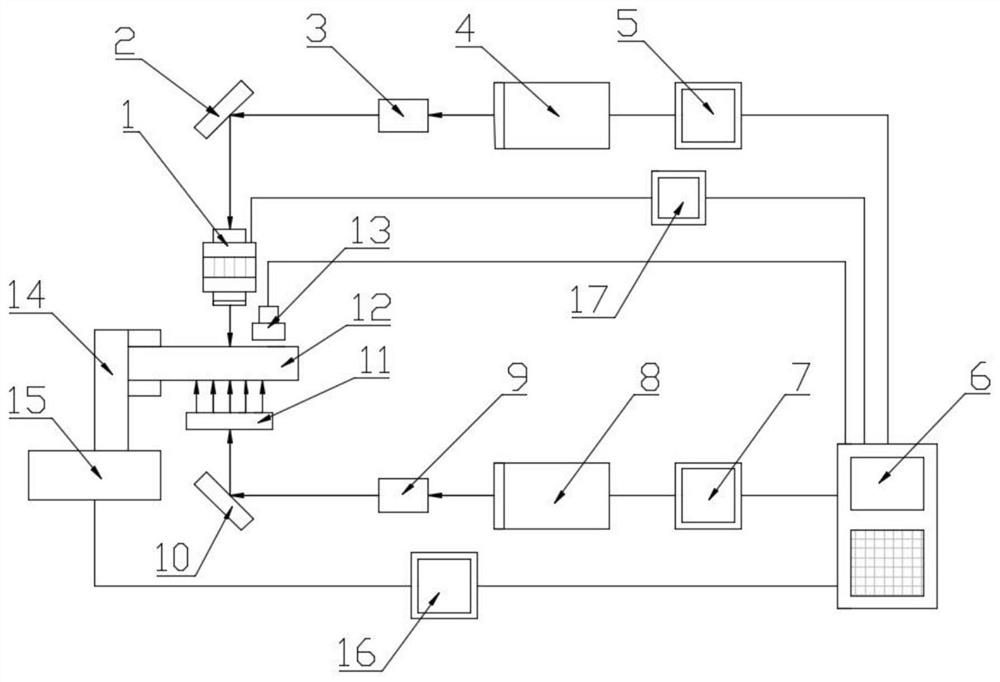

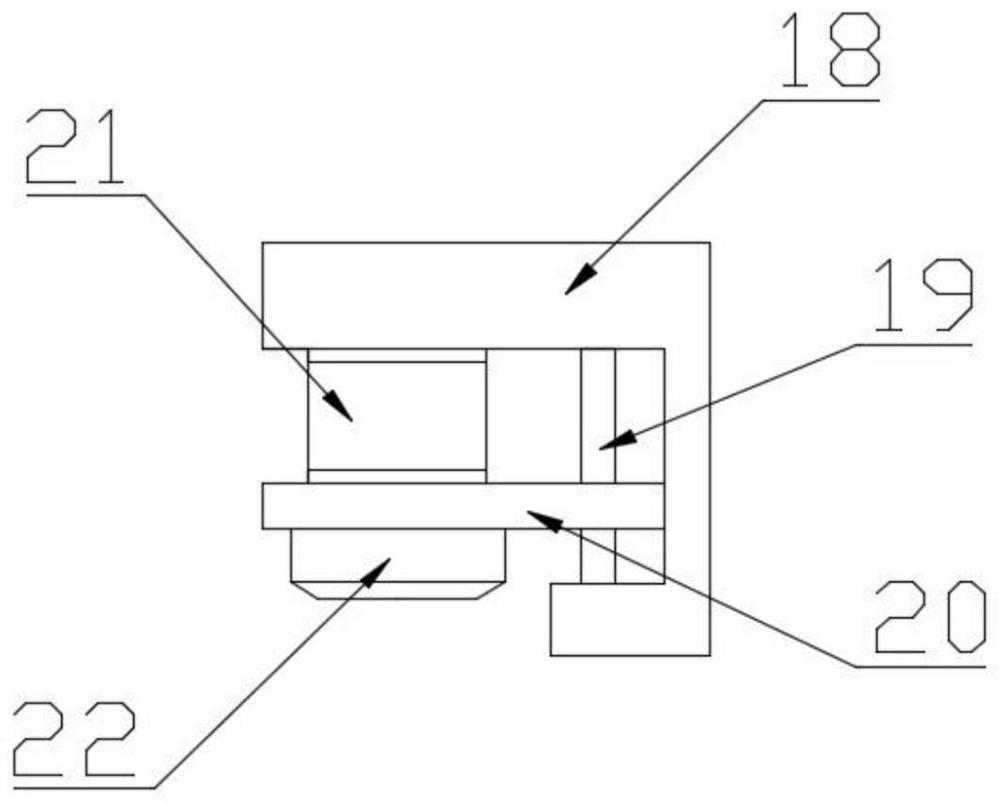

[0040] A laser ultrasonic technology-assisted pulse laser drilling device, characterized in that it includes a vibration module 1, a first reflective plane mirror 2, a first beam expander 3, a first pulse laser 4, a first pulse laser controller 5, and a computer 6 , second pulse laser controller 7, second pulse laser 8, second beam expander 9, second reflective plane mirror 10, beam splitter 11, workpiece 12, ultrasonic detector 13, fixture 14, working platform 15, working platform Controller 16, vibration module controller 17;

[0041] The first reflective plane mirror 2 is located at the top, and directly below it are the vibration module 1, the workpiece 12, the beam splitter 11 and the second reflective plane mirror 10; the workpiece 12 is fixed on the fixture 14, and the fixture 14 is fixed on the working platform 15; the ultrasonic probe 13 is installed on the upper side of the workpiece 12, not in contact with the workpiece 12; one end of the working platform controller...

Embodiment 2

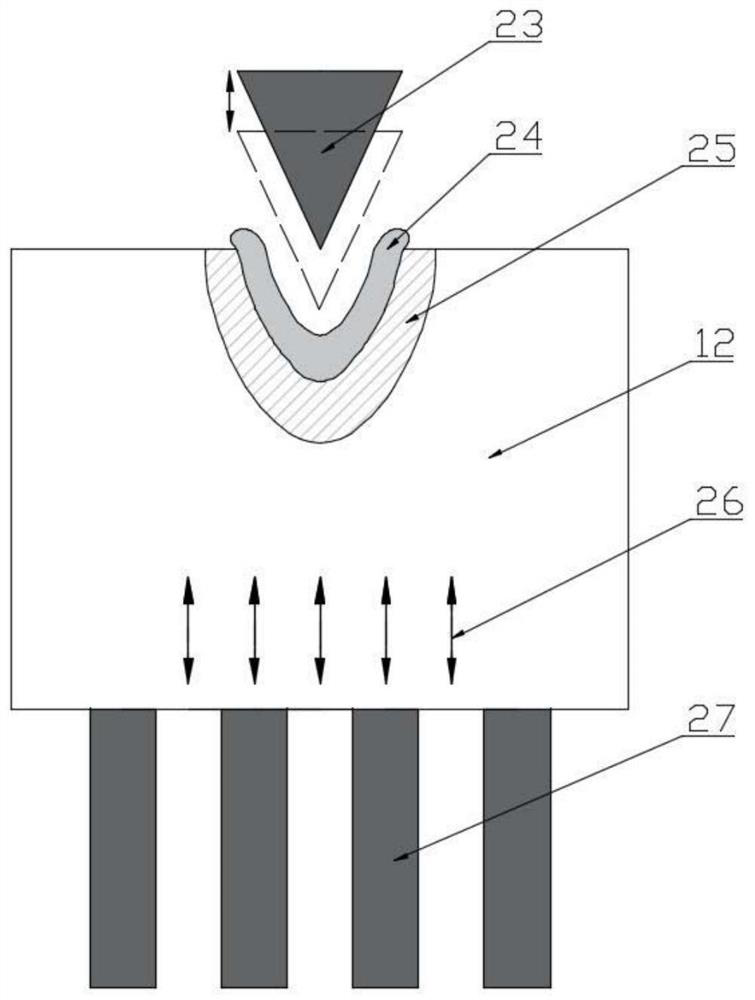

[0048] A laser ultrasonic technology-assisted pulse laser drilling method, before the first pulse laser 4 outputs the first laser beam 23 to process the workpiece 12, during the processing and for a period of time after processing, on the one hand, the second pulse laser 8 is used to output the first laser beam 23 Two laser beams, the second laser beam 27 after passing through the beam splitter acts on the lower surface of the workpiece 12, and part of the energy is absorbed by the material surface and converted into heat energy, causing the surface temperature of the material to rise rapidly, thereby causing the material to expand. The strain field and stress field are formed through the thermoelastic effect, thereby exciting high-frequency ultrasonic waves, which generate ultrasonic vibrations to assist laser drilling, promote the removal of molten materials in laser drilling, improve drilling efficiency, and reduce the thickness and microstructure of the recast layer. Cracks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com