Nominal diameter measuring instrument and measuring method for vacuum booster

A vacuum booster and nominal diameter technology, which is applied in the direction of mechanical diameter measurement, etc., can solve the problems of difficult to measure the diameter parameters of vacuum boosters, poor proximity, and low reliability, and achieve easy manufacturing, convenient use, and operating space requirements small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

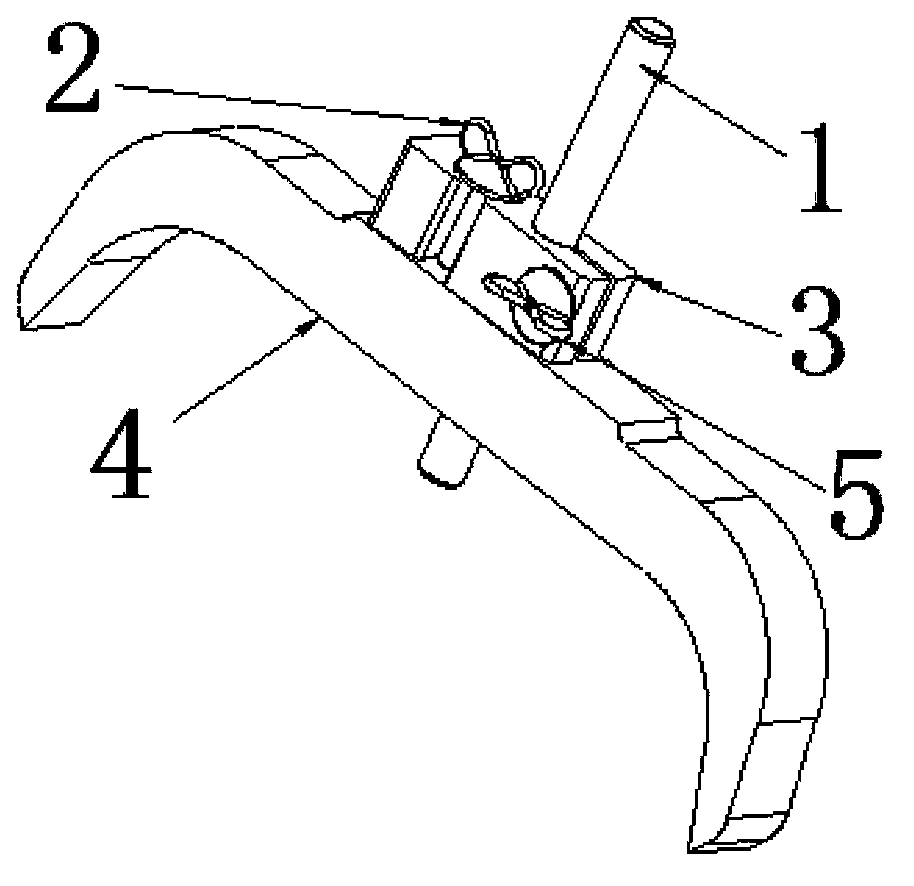

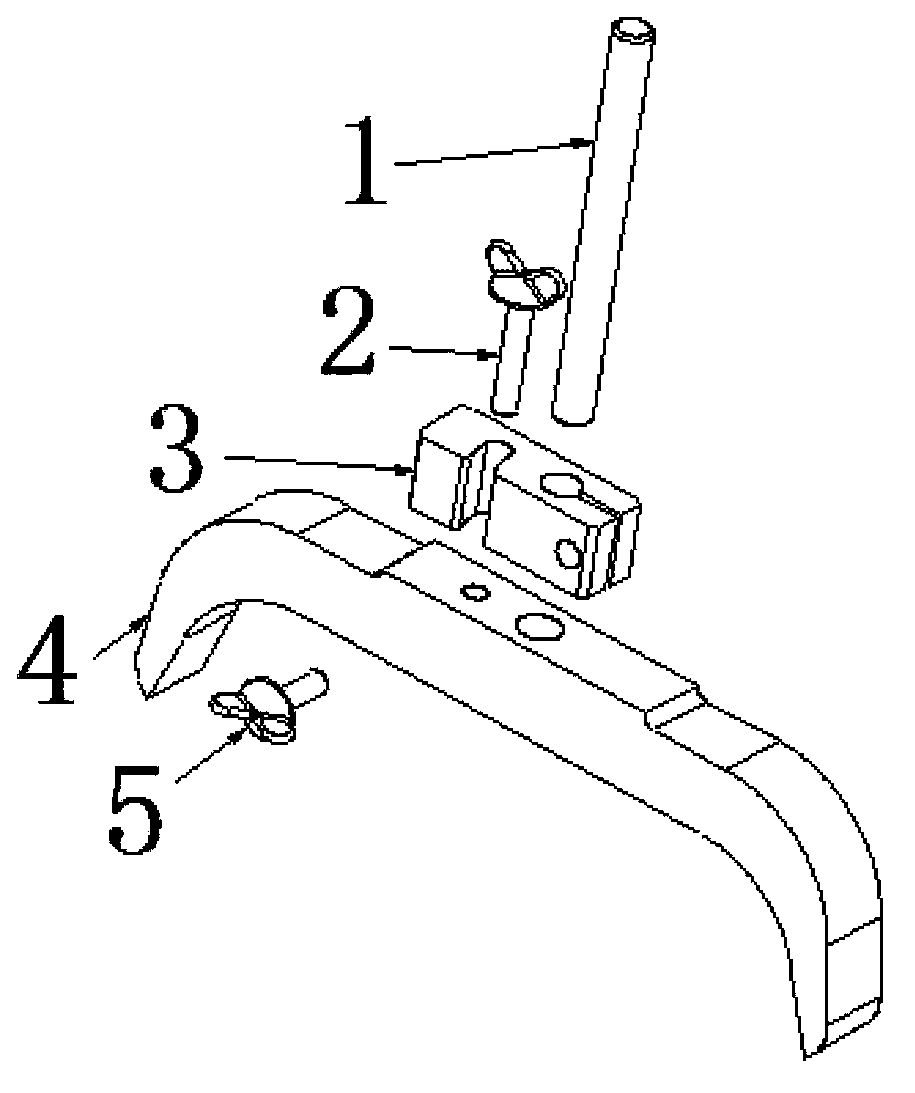

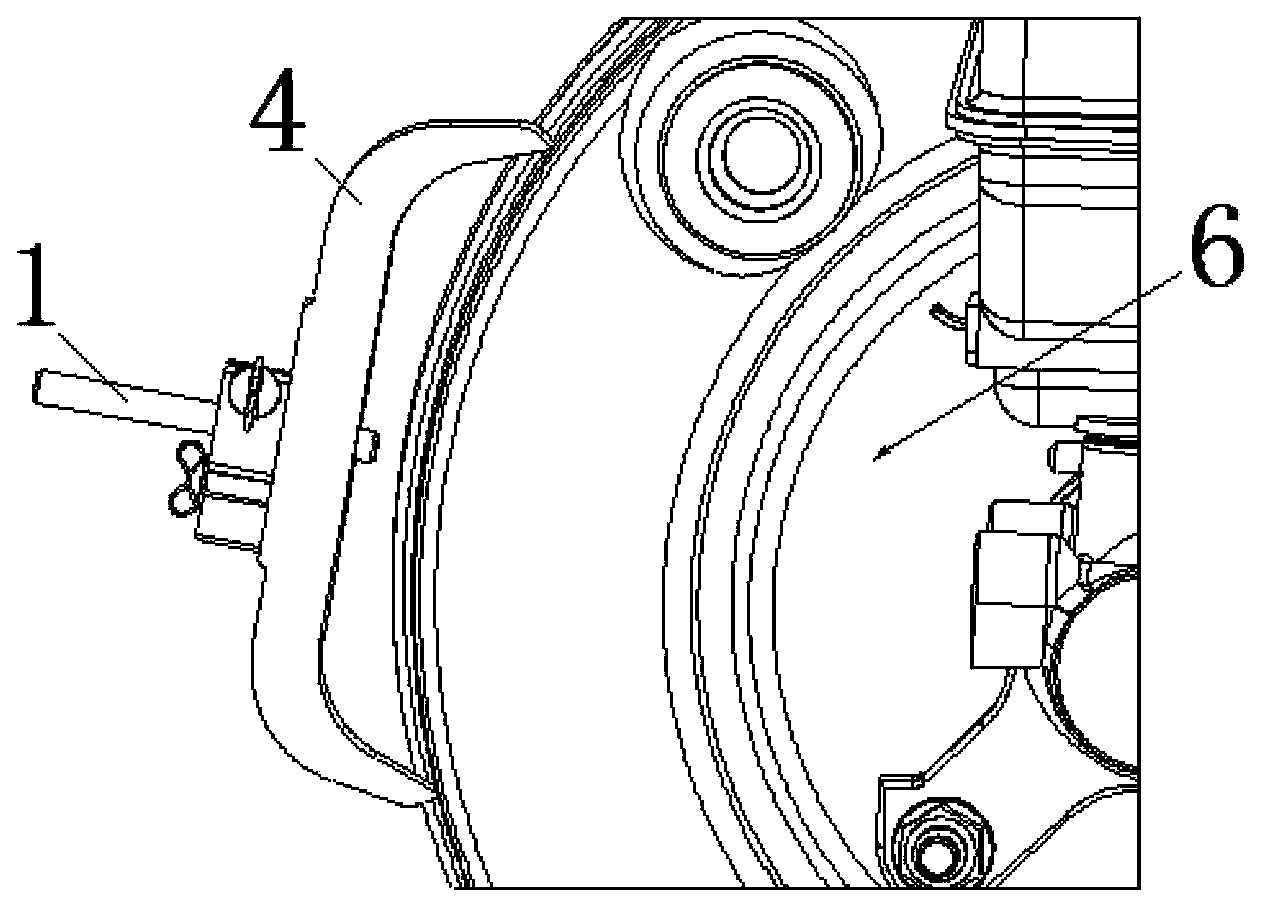

[0033] Such as figure 1 and figure 2 As shown, the vacuum booster nominal diameter measuring instrument includes a measuring rod 1, a claw 4 with two claws and a measuring rod fixture 3. During measurement, the two claws are stuck on the cylindrical surface of the vacuum booster 6, and the claw 4 The distance between the two claws is a fixed value, the upper part of the claw is provided with a measuring reference plane, and in the middle of the measuring reference plane, there is a through hole matching the measuring rod, and the measuring rod can slide in the through hole; beside the through hole There is a threaded hole, and a U-shaped groove is provided on the measuring rod fixture 3, and the measuring rod fixture 3 is fixed on the claw by hand-tightening the bolt I2 through the U-shaped g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com