Follow-up scraping mechanism for removing adhesion objects on anode plates

A technology for anode plates and adherents, applied in the direction of electrochemical sludge treatment, special treatment targets, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of increasing adherents, surface damage of anode plates, increased scraping and Difficulty and other issues, to achieve the effect of simple follow-up structure and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

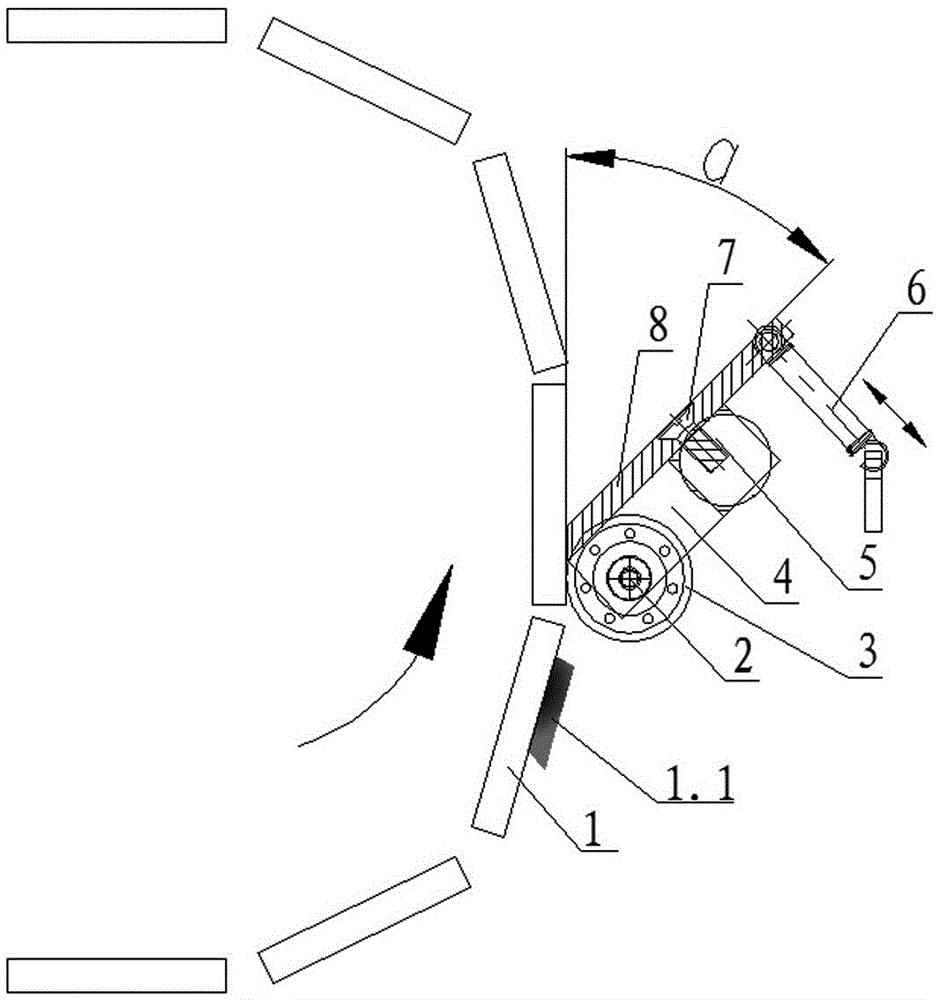

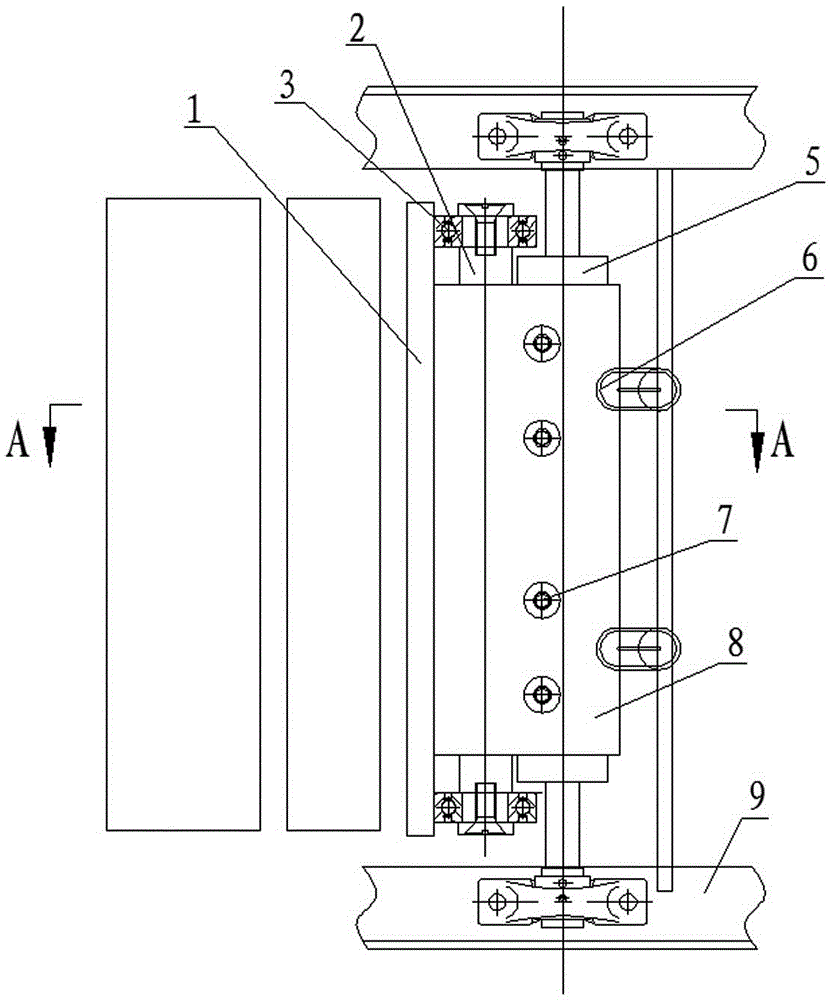

[0015] The follow-up scraping mechanism for removing anode plate adherents shown in the accompanying drawings is configured in the electro-osmotic sludge dewatering equipment, which includes an anode plate 1, a positioning shaft 2, a bearing 3, a plate 4, a knife shaft 5, a spring 6, Screw 7, scraper 8 and frame 9. The cutter shaft 5 is a slender shaft, the round shaft sections at both ends are equipped with bearing seats, and the middle section is a rectangular shaft section. The cutter shaft 5 straddles the supporting equipment frame 9 and is connected by a bearing seat, and the middle rectangular shaft section is connected with a plate-shaped scraper 8 by a screw 7 . The scraper 8 is inclined relative to the front surface of the matched anode plate 1, and the inclination angle α is an acute angle, and the inclination angle α=30° in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com