Reverse flow carbonization horizontal stove

A technology of horizontal furnace and inner cylinder, which is applied in furnaces, muffle furnaces, cooking furnaces, etc., and can solve the problem that the waste heat of retort furnaces cannot be recycled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

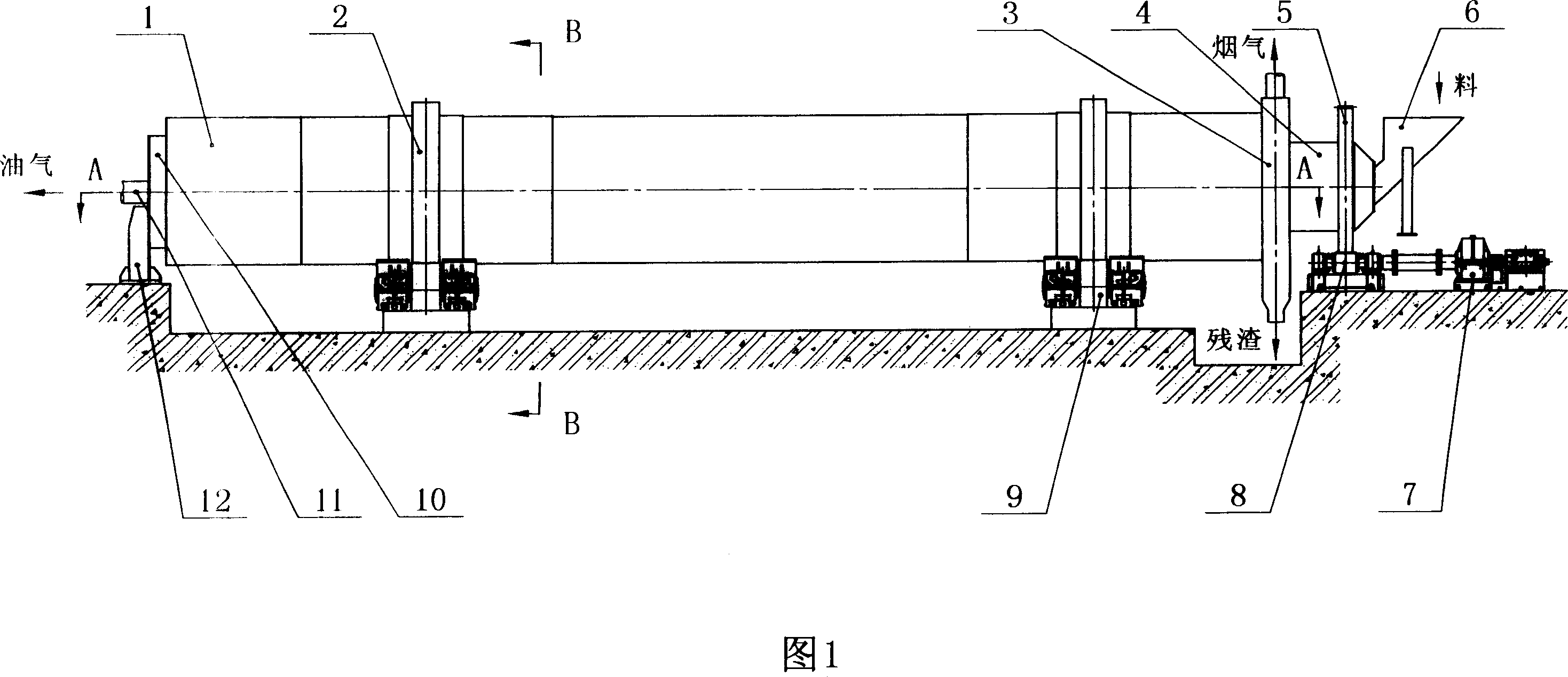

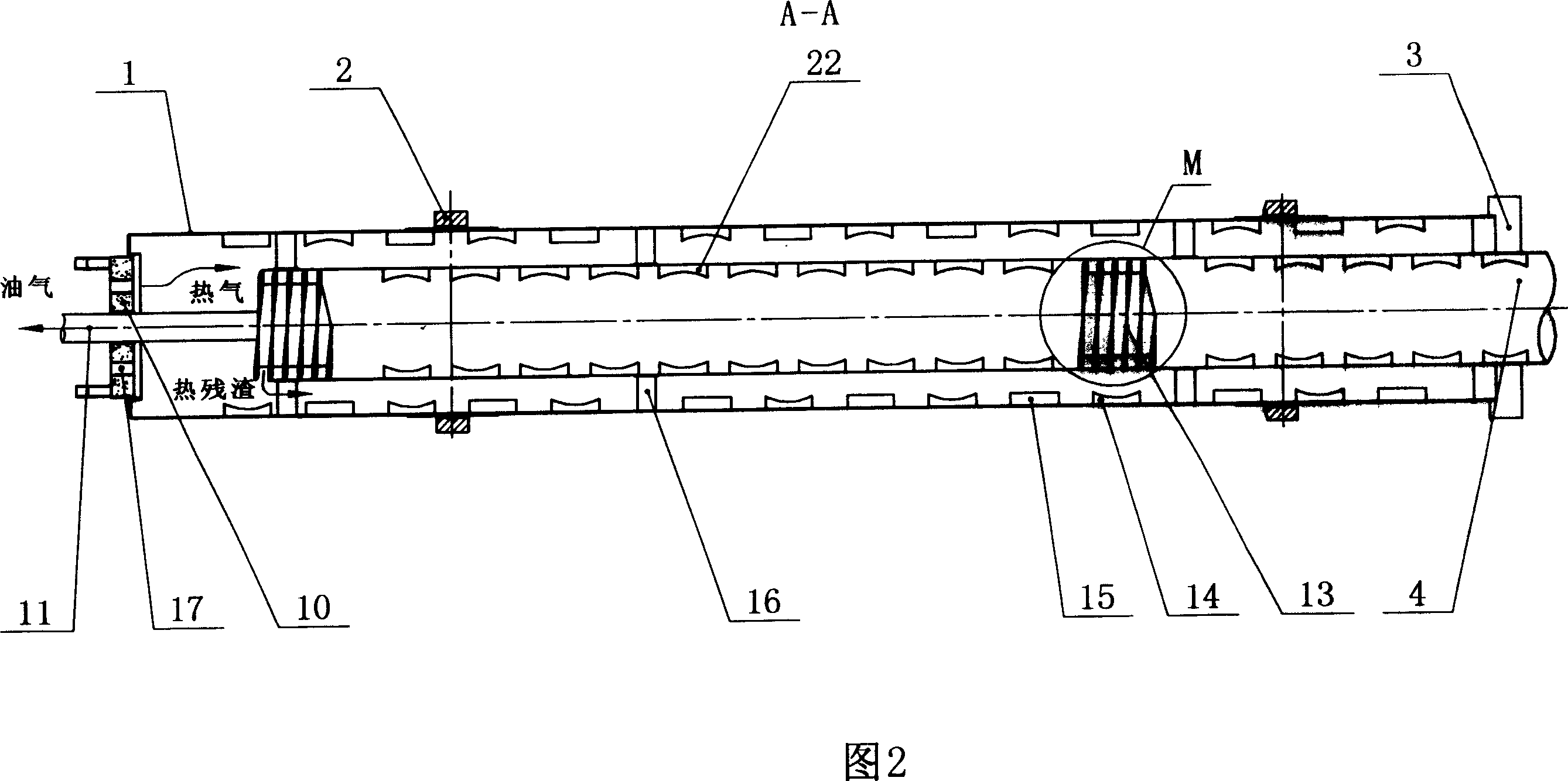

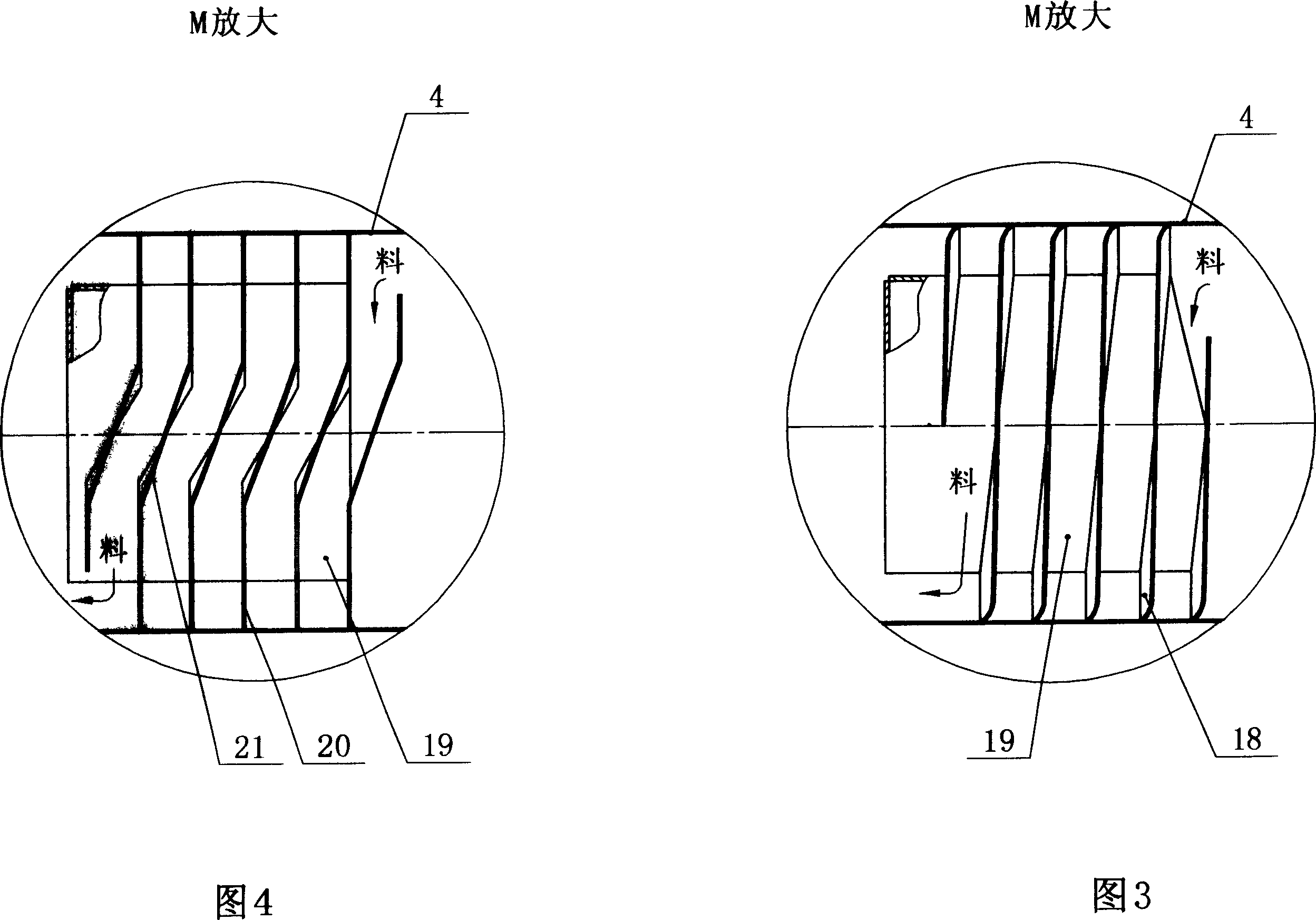

[0013] As shown in Fig. 1 and Fig. 5, the outer cylindrical body (1) is supported on the roller support device (9) through the tire belt (2). The inner cylinder (4) is fixed in the outer cylinder (1) through the inner support (16). Referring to Fig. 1 and Fig. 2, one end of the outer cylinder body 1 has an end cap (10) with a heat source hole (17), and the end cap (10) is fixed on the foundation through the end cap base (12), and the end cap (10) is connected to the There is a rotation gap between the outer cylindrical bodies (1). The other end of the outer cylinder body (1) has a smoke residue discharge cover (3), the inner cylinder body (4) protrudes outside through the smoke residue discharge cover (3), and the protruding part of the inner cylinder body (4) is equipped with The bull gear (5) is equipped with a feed port (6) on the end face of the protruding part, and the feed port (6) stretches into the inner cylinder (4). Feed inlet (6) is fixed on the foundation. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com