Low-calorific-value sludge harmless, volume-reductive and resourceful treatment technology and device

A treatment device and low calorific value technology, applied in sludge treatment, water/sludge/sewage treatment, fixed/solidified sludge treatment, etc. The process is simple and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to better understand the present invention, the embodiments of the present invention will be explained in detail below with reference to the accompanying drawings.

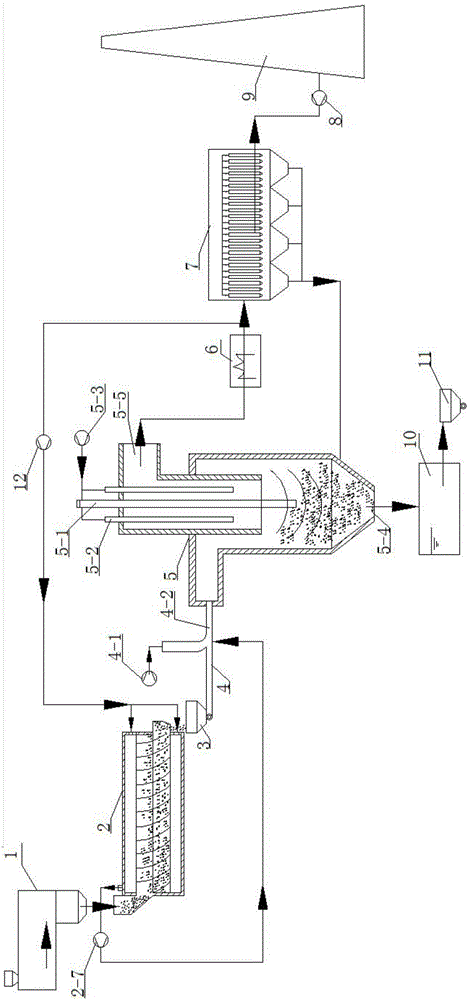

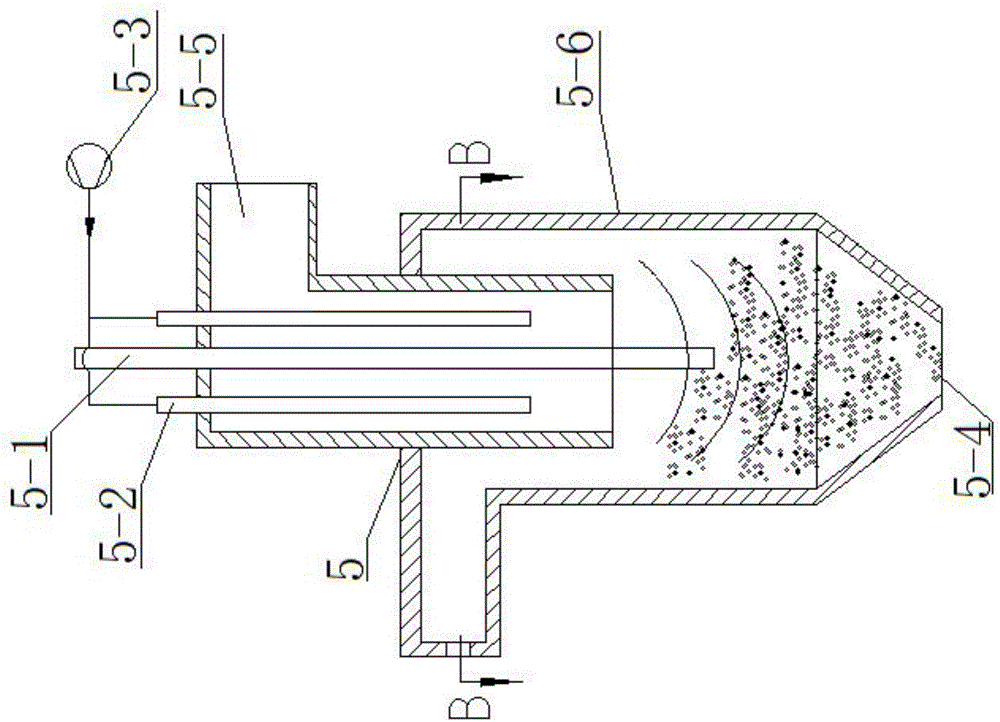

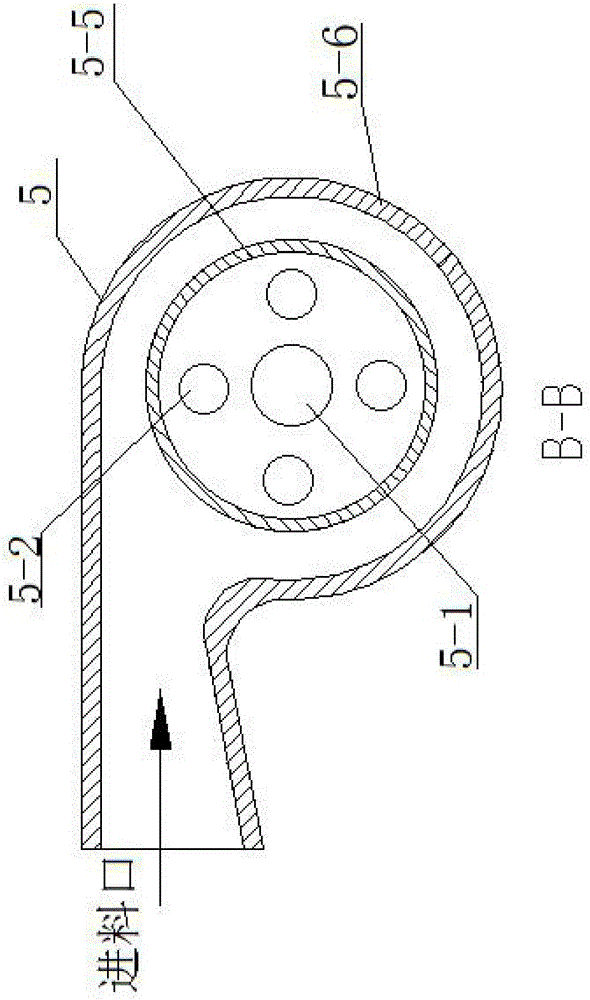

[0045] Figure 1 to Figure 6 It is an embodiment of the present invention. The daily output of sludge from an industrial wastewater treatment plant in H city is 500 tons. After preliminary treatment, the water content of the sludge is 60%, which is a low-calorie sludge. figure 1 It is a schematic diagram of the overall structure of the device for processing. Low calorific value sludge three treatment equipment, including sludge drying system, plasma cyclone incineration device, wind and smoke system, flue gas waste heat recovery system 6, slag discharge system, dust removal system, chimney 9, and the discharge port of the sludge drying system Connect the inlet of the plasma cyclone incinerator, the exhaust port of the plasma cyclone incinerator is connected to the inlet of the flue gas waste heat recov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com