Glass footbath and making method thereof

A footbath and glass technology, applied in glass manufacturing equipment, glass forming, glass tempering, etc., can solve problems such as damage, hidden safety hazards, cracks, etc., to enhance the observability, and it is not easy to accumulate dirt , the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

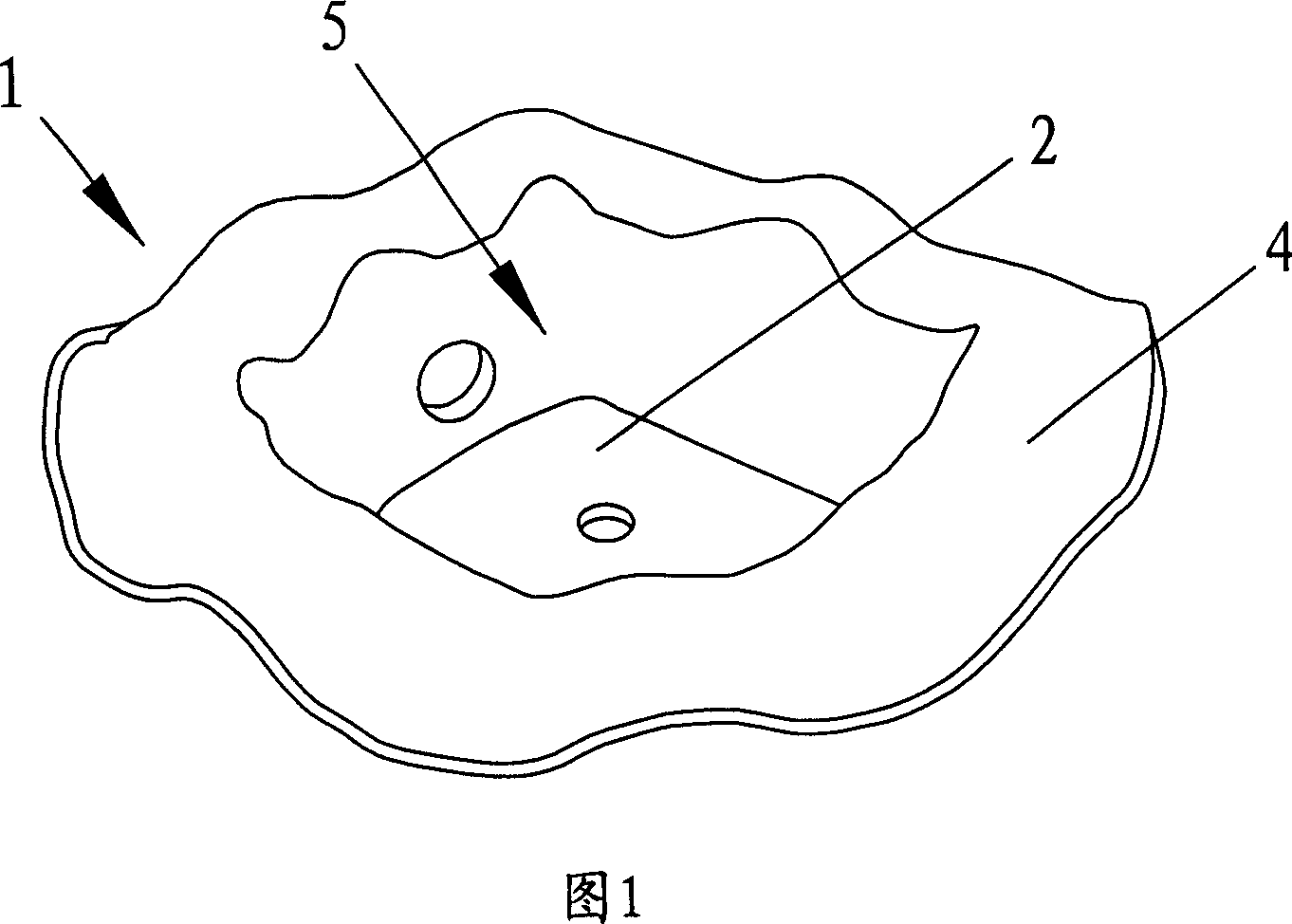

[0025] Referring to Fig. 1 , the glass footbath includes a basin body 1, which is characterized in that: the basin body 1 is made of tempered glass. Therefore, the glass footbath of the present invention is not easy to accumulate dirt, is transparent, neat and beautiful, is not easy to be damaged, and has the advantages of safety.

[0026] Wherein, the bottom surface 2 of the pot body 1 is a plane. Thereby, the bottom surface of the basin body can be fully contacted with the flat ground or the table, so that the glass footbath made by the present invention can stand on the flat ground or the table relatively stably; and due to the characteristics of glass, the glass made by the present invention can The footbath has the advantage of being resistant to wear and tear.

[0027] Wherein, a high-temperature glaze layer is sprayed on the surface of the basin body 1, so that the glass footbath of the present invention looks elegant in appearance. Among them, in order to prevent the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com