Spiral hollow coil current transformer with compensating coils

A technology of current transformers and air-core coils, applied in the direction of inductors, instruments, circuits, etc., can solve the problems of electromagnetic current transformers, such as susceptibility to electromagnetic interference, coil resistance, area, volume increase, high cost, etc., to achieve improved Measurement accuracy and anti-electromagnetic interference ability, improved saturation characteristics and linearity, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

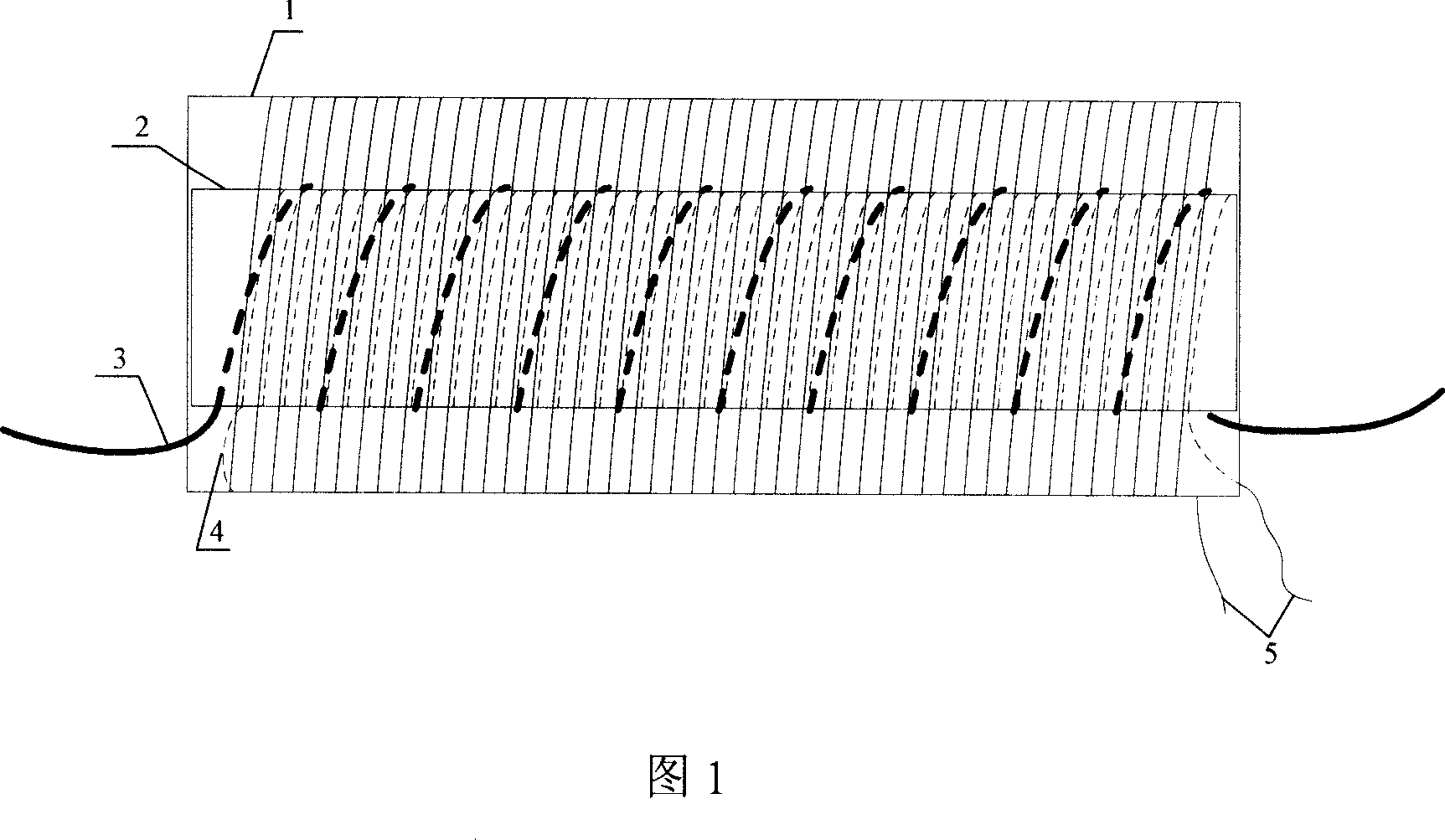

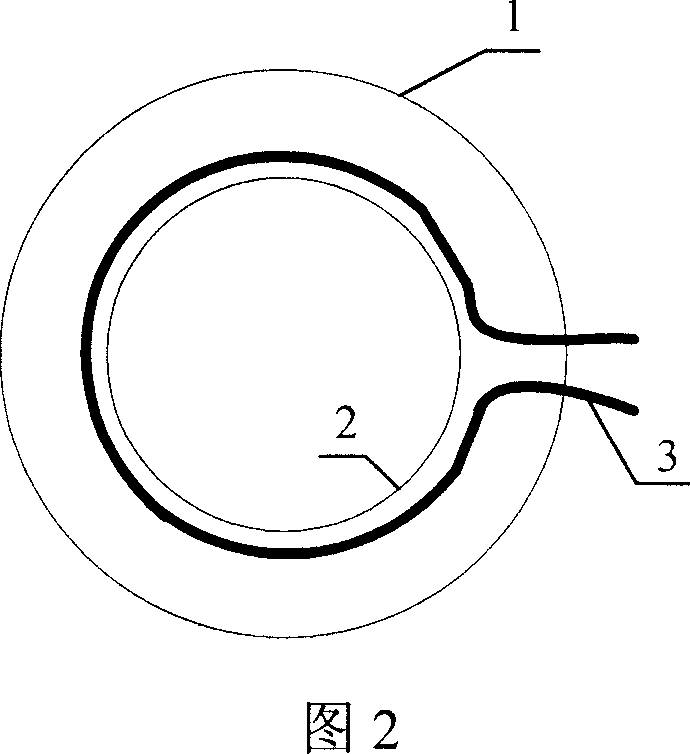

[0014] Refer to Figure 1 and Figure 2. Figure 1 is a schematic structural diagram of an embodiment of the present invention. In the figure, 2 is the secondary spiral tube sensing coil, and 1 is the secondary compensation spiral tube hollow coil that cancels the interference of the external magnetic field. The two are uniformly and tightly wound by the same enameled fine copper wire to form a spiral tube of the same length, each layer The number of turns of the coils is the same, and the winding directions of the two coils are the same, the head end or the end are connected, the spiral 1 has a layer of air-core coils, and the spiral 2 has three layers of air-core coils. 3 is the primary spiral tube coil, which is wound around the spiral tube sensing coil 2 to form a spiral tube, so that the secondary sensing coil can be more strongly coupled to the primary coil, which facilitates the increase or decrease of the mutual inductance, and can meet the requirements of the power system. R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com