Screw pump and screw gear

A technology of helical gears and helical strips, applied in the field of helical gears, can solve problems such as inability to accommodate helical gears and poor degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

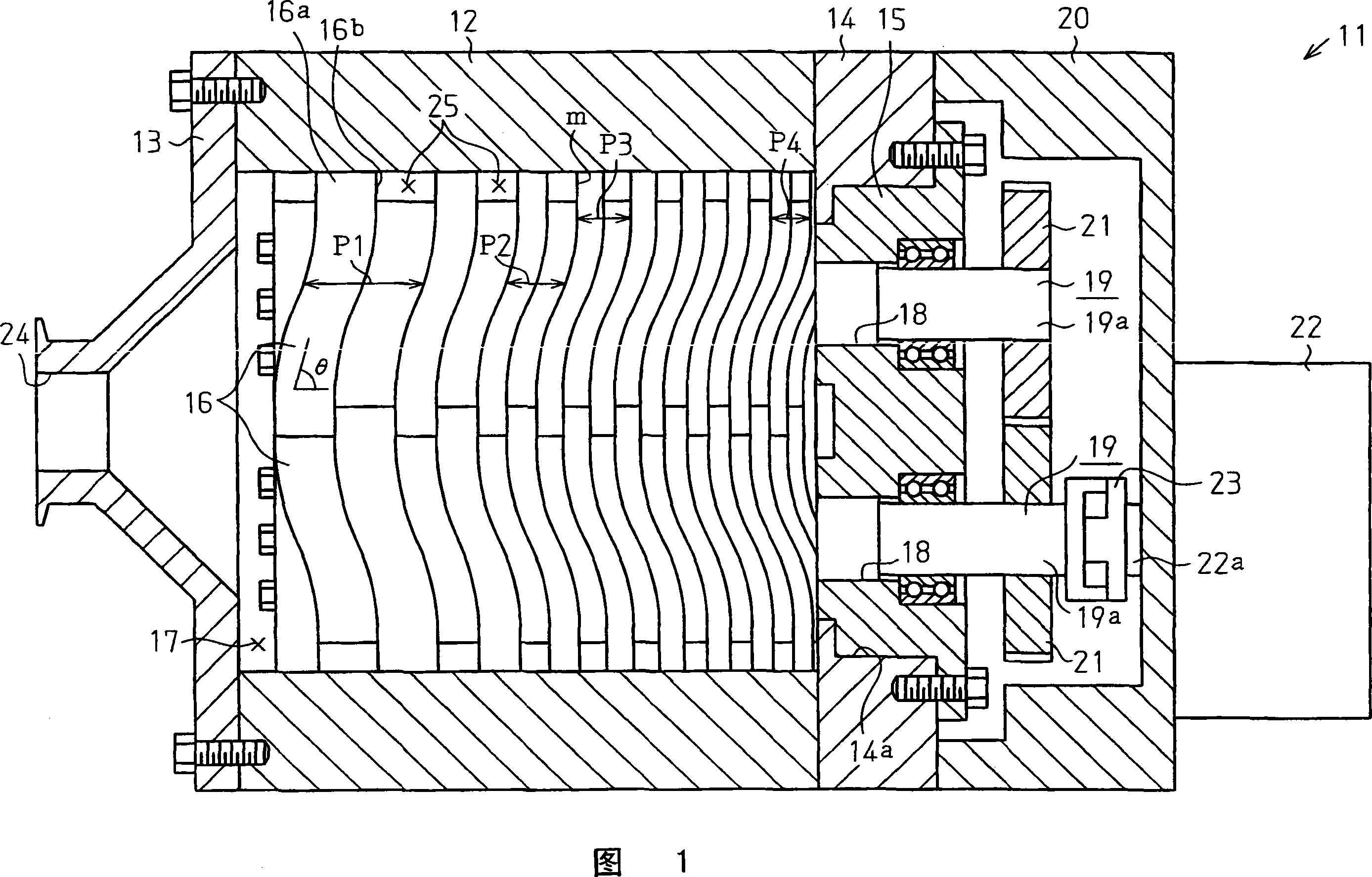

[0021] Next, an embodiment of the present invention will be described with reference to FIGS. 1 to 3( b ).

[0022] As shown in FIG. 1 , a screw vacuum pump 11 according to this embodiment has a cylindrical rotor case member 12 and a cover-shaped front case joined to the front end (left side in FIG. 1 ) of the rotor case member 12 . The body member 13 and the plate-shaped rear case member 14 joined to the rear end (right side in FIG. 1 ) of the rotor case member 12 . A stepped mounting hole 14 a is formed in the rear housing member 14 , and the bearing body 15 is fixed to the rear housing member 14 by bolts while being fitted in the mounting hole 14 a. A pair of helical rotors (helical gears) 16 functioning as a fluid conveying body are housed in the rotor case member 12 . A pump chamber 17 is formed between the outer peripheral surface of these screw rotors 16 and the inner peripheral surface of the rotor case member 12 . In addition, the concrete structure of the said scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com