Rigid axle assemblies and fixed brackets in vehicles

A fixed bracket, rigid technology, applied in the direction of vehicle components, elastic suspension, suspension, etc., can solve the problems of asymmetry, fork link and drive shaft layout restrictions, etc., to achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

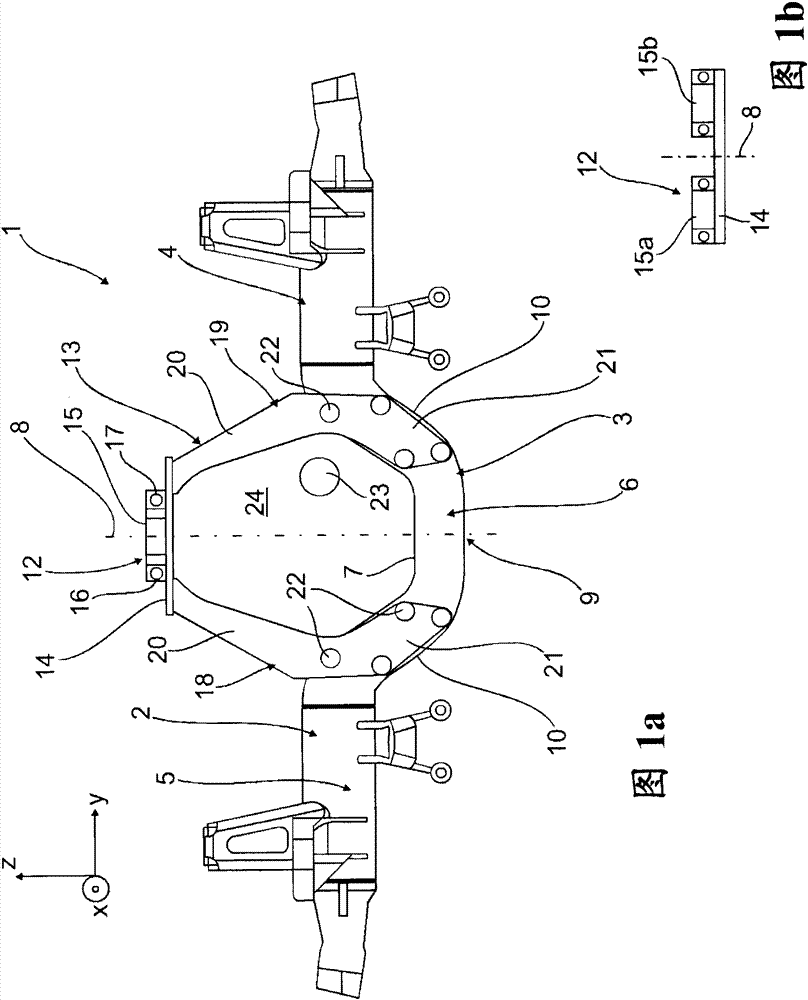

[0025] Figure 1a Shown is a rigid bridge 1 with a combined pontic 2 having a pontic middle part 3 and a pontic side part 4 joined, in particular welded or flanged, to the pontic middle part 3, 5. In this case, the individual bridge components can be constructed according to the concept of DE 103 33 760 A1.

[0026] The bridge body 2 is provided with a raised area 6 in the region of the bridge body center part 3 , wherein the raised area 7 is directed downwards as viewed in the direction z of the vertical vehicle axis.

[0027] as available from Figure 1a As further obtained in , the projecting region 6 of the bridge body center part 3 extends almost horizontally on both sides of the longitudinal center region 9 of the bridge body 2 delimited by the center axis 8 and thus essentially in the direction of the vehicle transverse axis y extend. Bridge body transition regions 10 , 11 extending obliquely or curved with respect to the vehicle vertical axis direction z and the vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com