Cascaded stack with gas flow recycle in the first stage

一种再循环、再循环系统的技术,应用在电气元件、燃料电池、燃料电池分组等方向,能够解决性能劣化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following description of the preferred embodiments is merely exemplary in nature and is not intended to limit the invention, its application, or uses.

[0021] As used herein, the term "fluid" means any gaseous and / or liquid material such as, but not limited to, liquid water, water vapor, and combinations thereof.

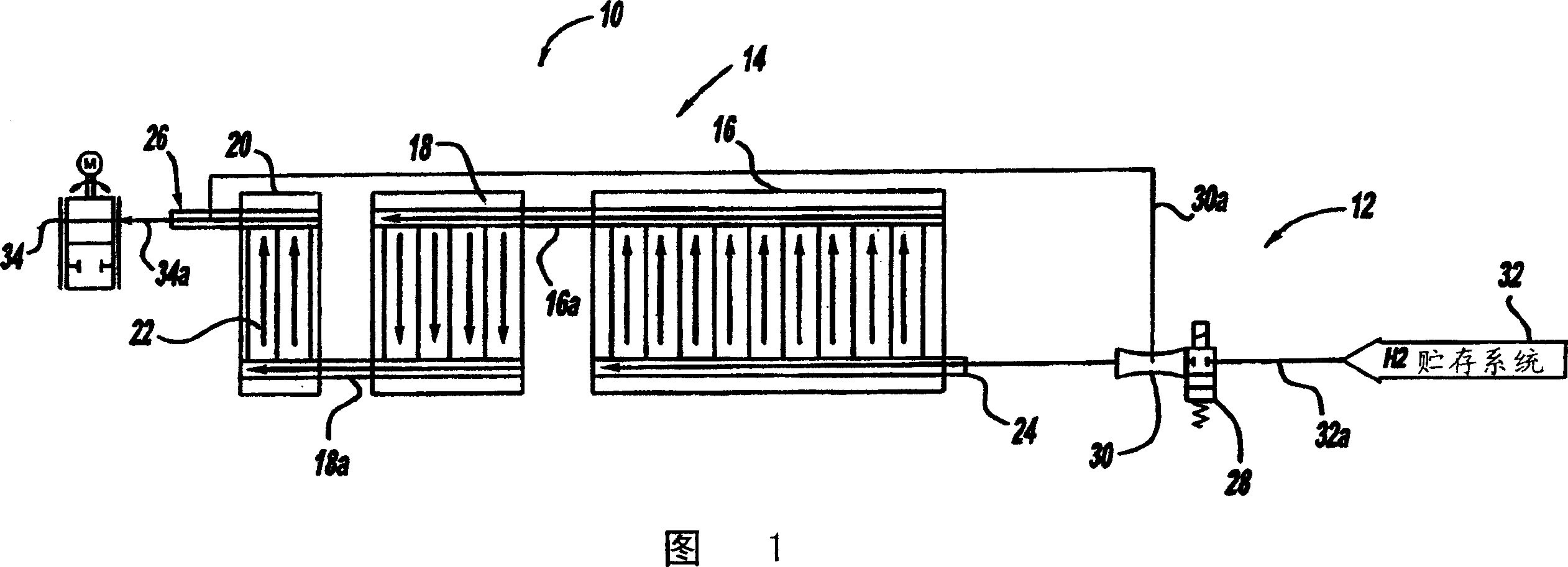

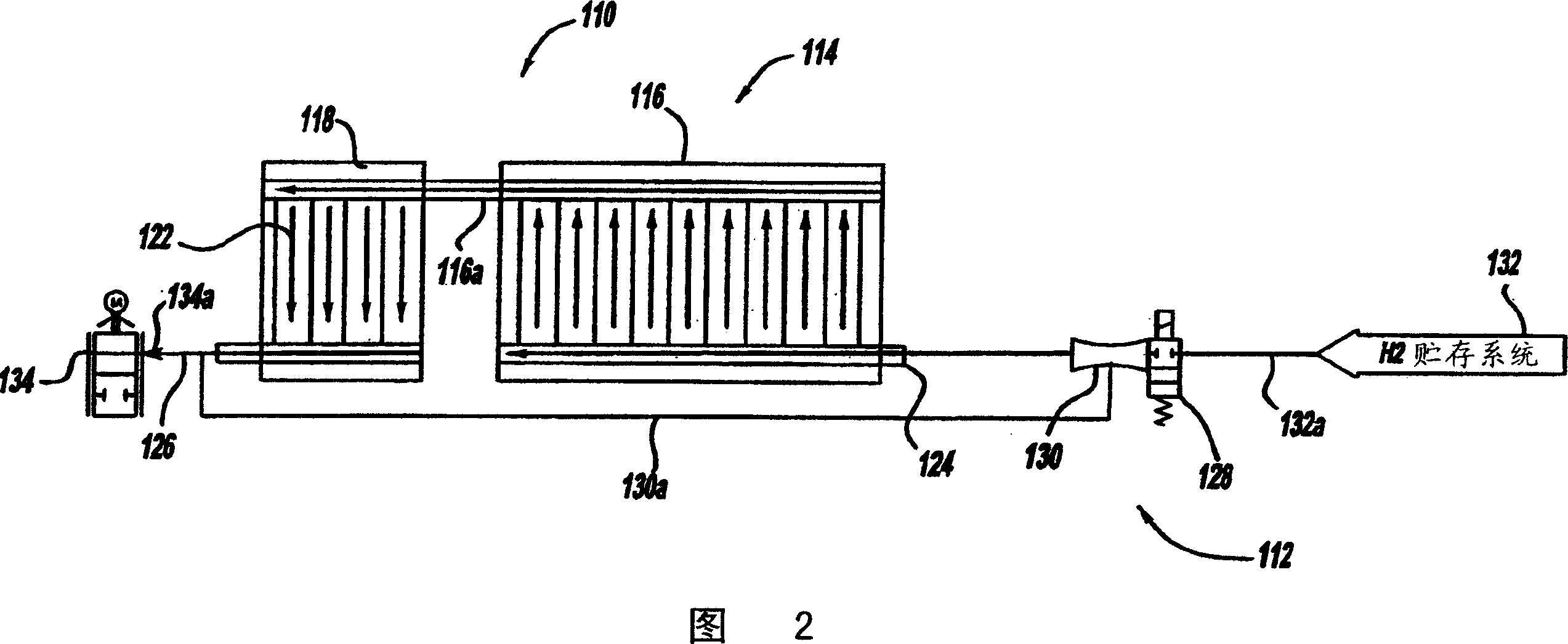

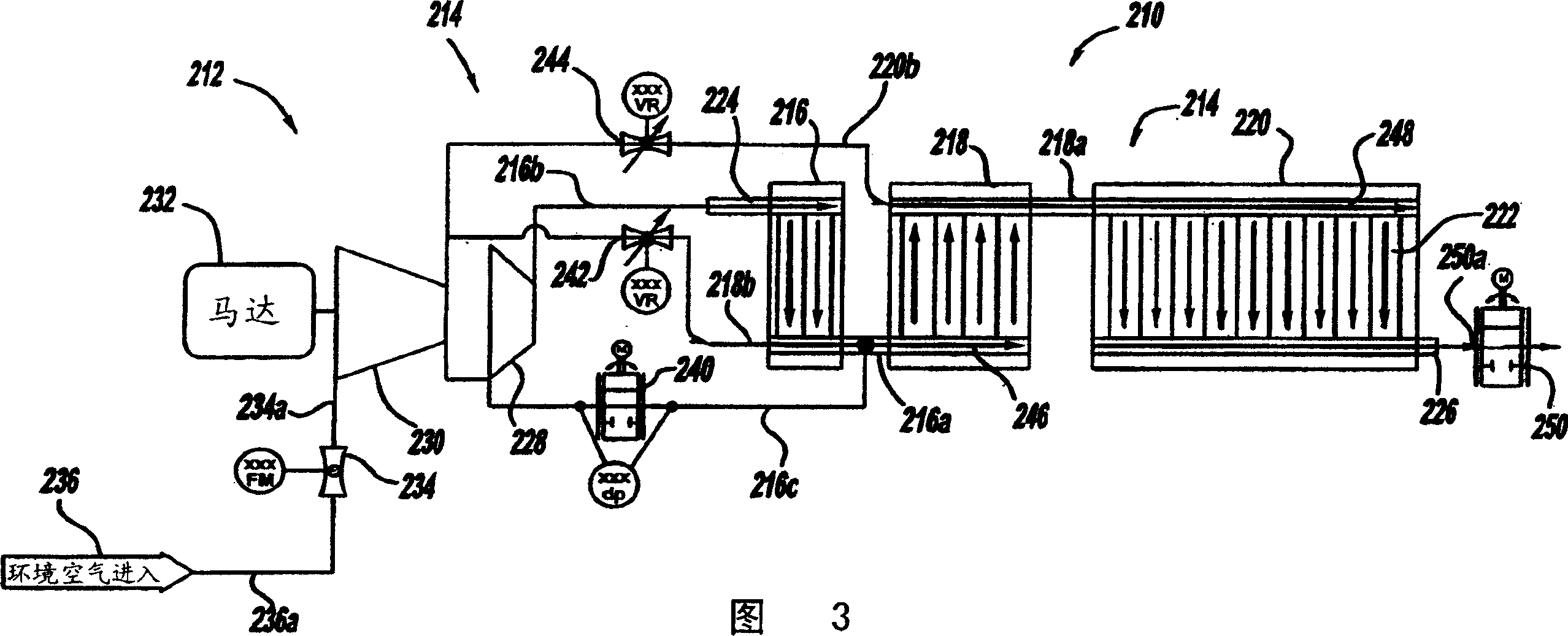

[0022] Referring to FIG. 1, a schematic diagram of a three-stack fuel cell system 10 having a humidification / gas recirculation system 12 operative with respect to the anode flow 14 side of the stack is shown in accordance with one embodiment of the present invention.

[0023] The fuel cell system 10 includes three respective fuel cell stacks 16, 18, 20 in fluid communication with each other, or at least with adjacent fuel cell stacks. The fuel cell stacks 16 , 18 , 20 each contain a plurality of individual fuel cell elements 22 . The number of fuel cell elements 22 in the fuel cell stacks 16, 18, 20, respectively, may vary. Conduit 16a and 18a are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com