Welding steel floor

A steel floor, welding technology, applied in the direction of floor, building, building structure, etc., can solve the problems of heavy steel floor, large equipment investment, high production cost, and achieve light weight, low production cost and convenient production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

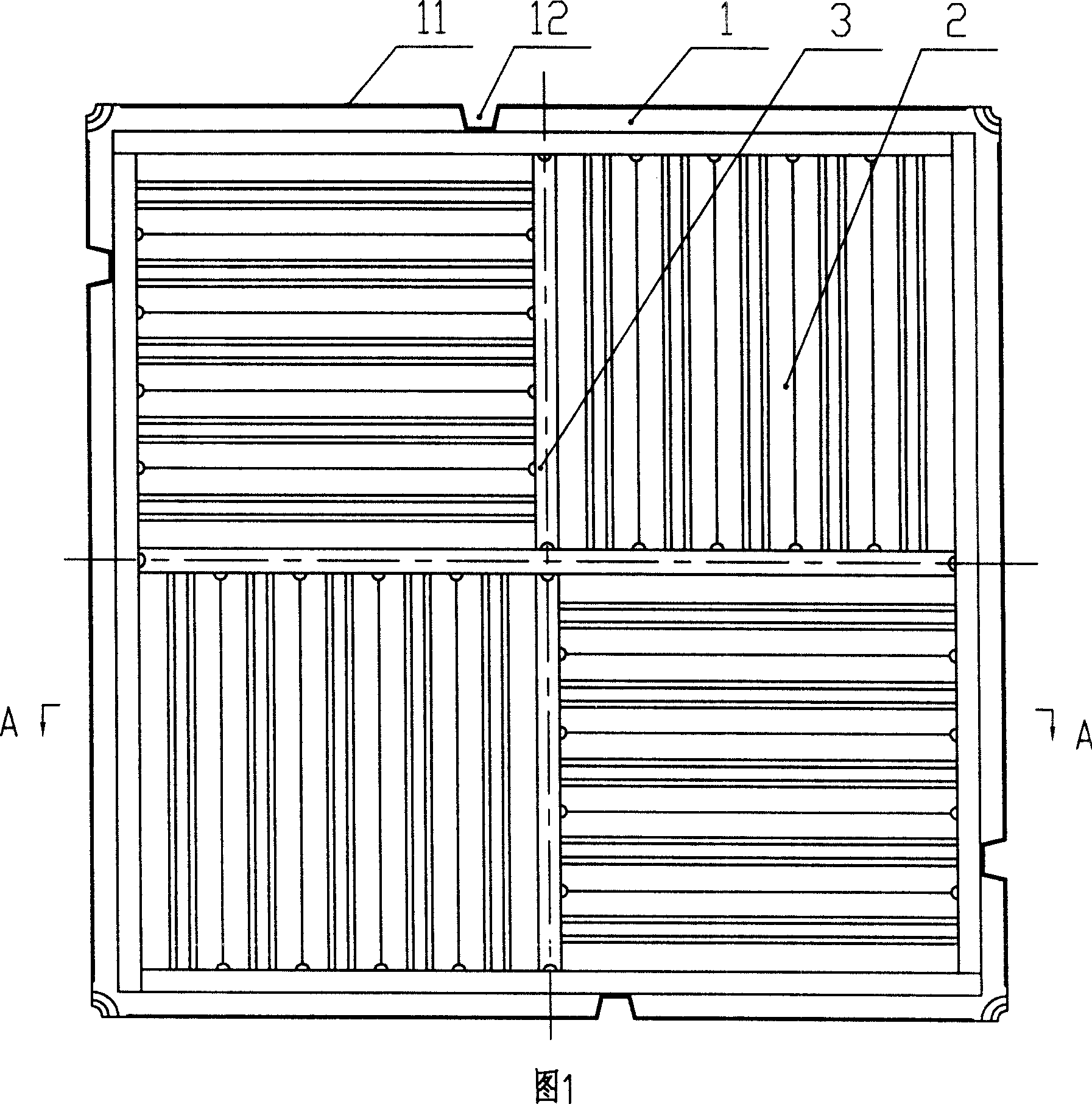

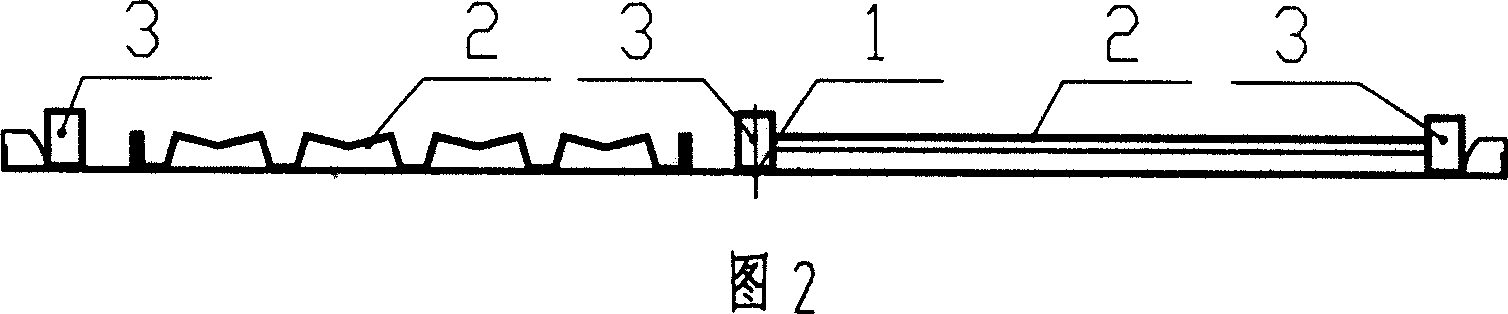

[0014] The welded steel floor of the present invention as shown in Figure 1 and Figure 2 includes a panel 1, the four sides of the panel 1 have flanges 11 extending downward along the panel surface, the flanges 11 are perpendicular to the panel surface, and the four corners of the panel 1 are bent downward Folded into a 1 / 4 dish shape, the top of the corner is concave arc, the four sides of the panel 1 are provided with openings 12, the back of the panel 1 is welded with a reinforcement plate 2 and a "Tian"-shaped reinforcement frame 3, and the reinforcement plate 2 is a wave-shaped folding plate , the crease directions of the two reinforcing plates 2 on the same side are perpendicular to each other, and the reinforcing plates 2 are arranged in the strengthening frame 3 in the shape of a "field".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com