Sampling analysis device with powder filtering filtration function

A sampling analysis and filtration technology, applied in the direction of sampling device, test sample preparation, etc., can solve the problems of sample delay, pipeline leakage, removal, etc., and achieve the effect of reducing the amount of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

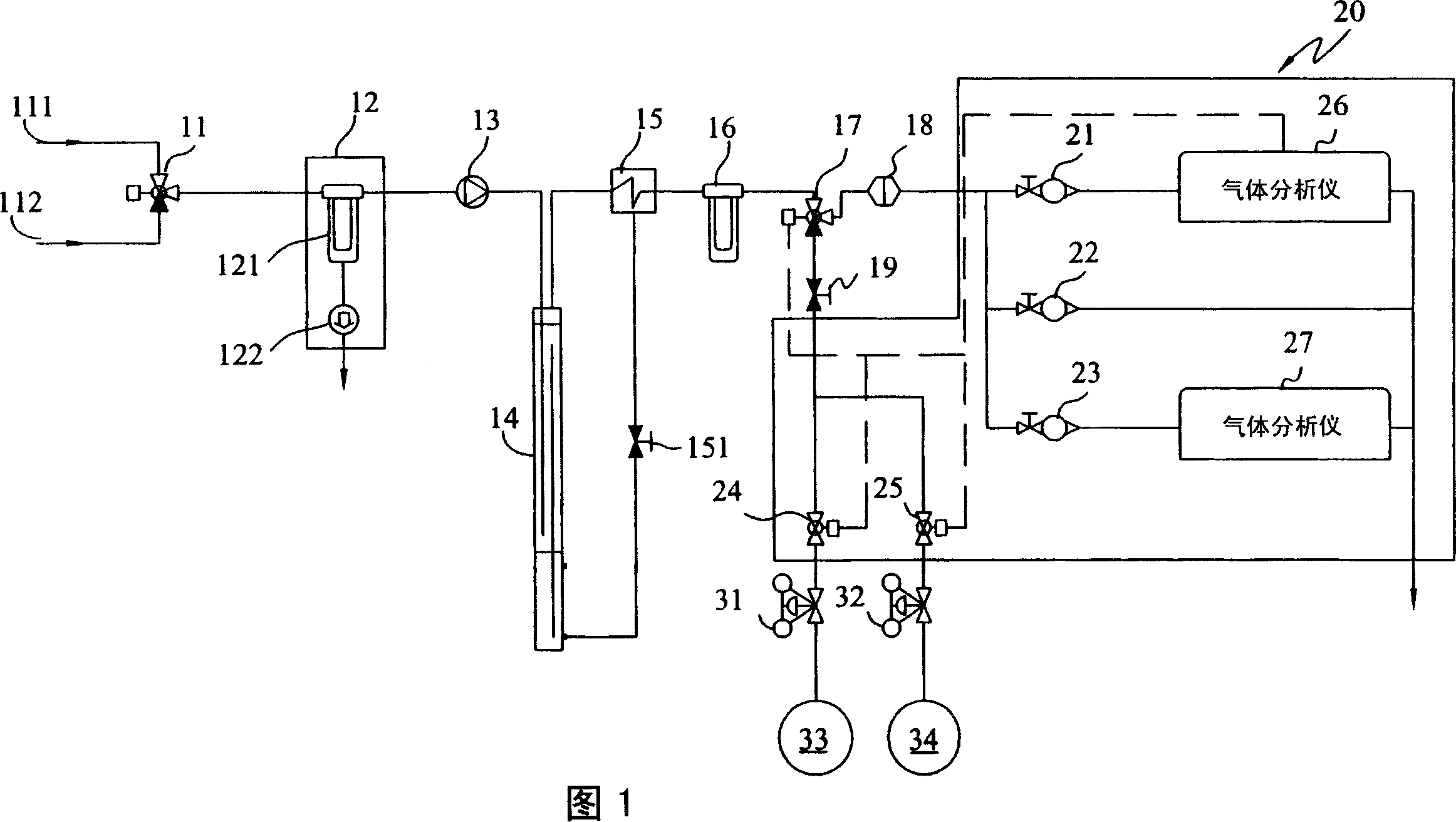

[0026] Relevant detailed content and technology of the present invention, cooperate accompanying drawing to illustrate as follows:

[0027] According to the sampling analysis device with dust filtering function of the present invention, please refer to Fig. 1, the check valve (Check valve, swagelok) 11 utilizes two sampling pipes 111, 112 to guide the flue gas of the flue to enter, the better state In order to sample the flue gas upstream (inlet sample gas) and downstream (outlet sample gas) of the flue (not shown in the figure), similarly, multi-point sampling can also be added, and the changes are the same. Simultaneously, can utilize air extraction pump (Diaphragm pump) 13 to assist to introduce flue gas forcibly, then comprise coarse filter module 12, scrubber (scrubber) 14, cooler 15, after fine filter module 16 in sequence, by analysis module 20 Sampling and analysis is carried out, so the dust in the flue gas is removed by segmental filtration.

[0028] Firstly, the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com