Beverage automatic filling production line

A production line and beverage technology, applied in the field of single-cup beverage automatic production, can solve the problems of no detection mechanism, many processing stations, and low product accuracy, so as to avoid manual weighing, reduce labor costs, and improve the degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

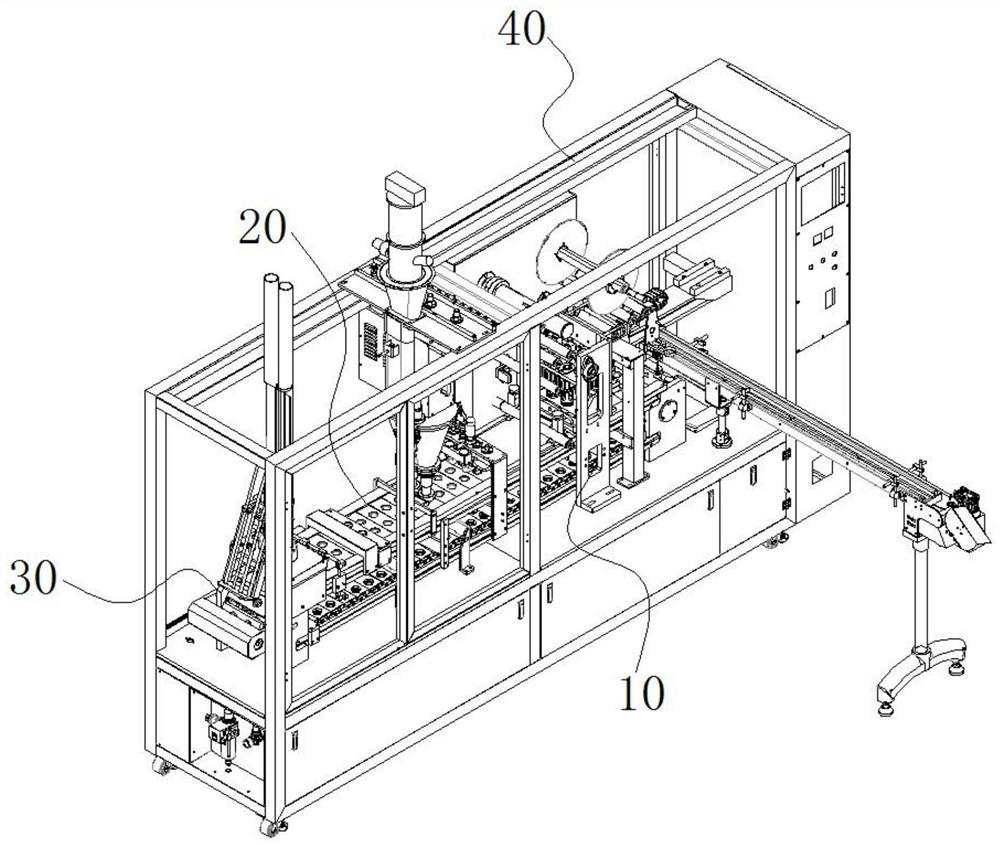

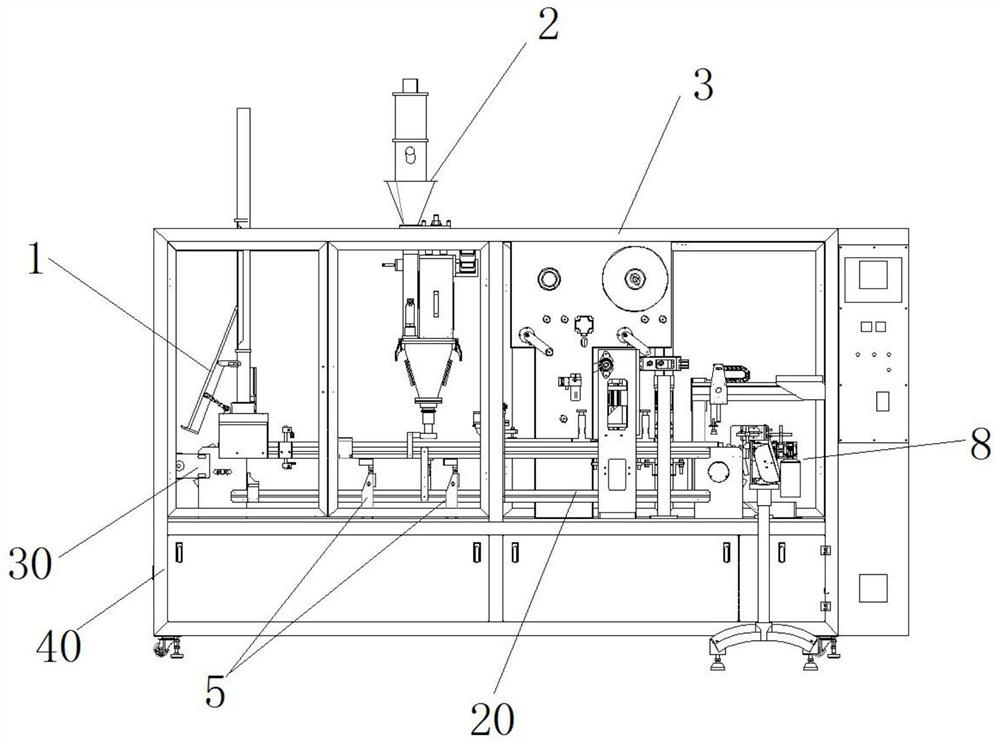

[0092] refer to Figure 1 to Figure 4 An automatic beverage filling production line, comprising: a mounting frame 40, a conveying chain plate 20 arranged on the mounting frame 40, a power device 30 disposed on both ends of the conveying chain plate 20 and fixed on the conveying chain plate 20 and the mounting frame 40 connected processing device 10;

[0093] It is characterized in that the processing device 10 includes: an automatic cup dropping device 1 arranged and fixed on the mounting frame 40 according to the processing procedure, a filling device 2, a sealing film welding and cutting integrated device 3 and an automatic cup dropping device arranged on the conveying chain plate 20 away from the automatic cup dropping device. 1 a cup outlet device 8 at one end;

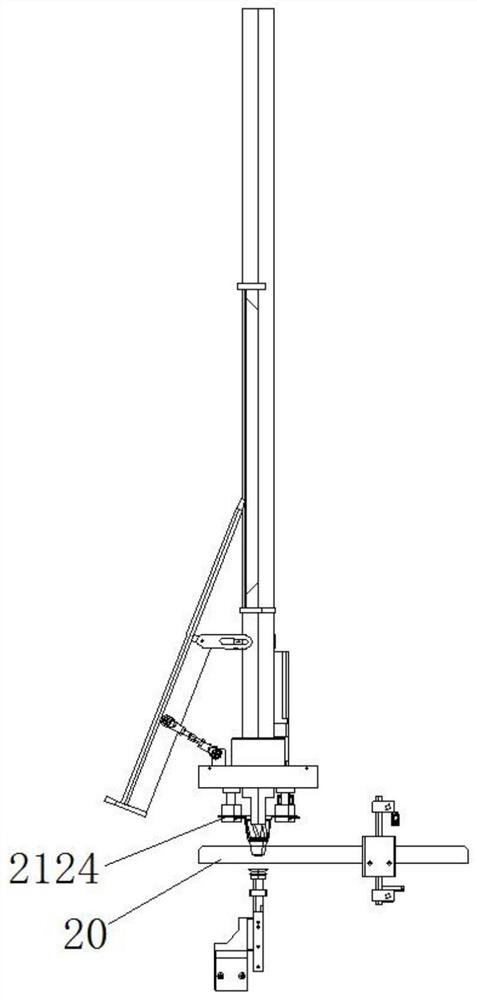

[0094] Among them, the automatic cup drop device 1 is provided with a servo spiral cutter 2124, after the servo spiral cutter 2124 separates the cup, the suction cup device 1131 arranged at the bottom absorbs the...

Embodiment 2

[0098] refer to Figure 5 and Figure 6 , the difference from the above embodiment is that the automatic cup drop device 1 includes: a base 13, a cup drop assembly 11 arranged on the base 13, and a cup drop monitoring assembly 12 arranged adjacent to the cup drop assembly 11;

[0099] Wherein, the falling cup assembly 11 includes a blanking part 112 arranged on the base 13, a feeding part 111 arranged on one side of the blanking part 112, and a blanking auxiliary part 113 arranged below the blanking part 112; wherein, the blanking Part 112 separates bottom adjacent cups 14 by means of servo helical cutter 1124 .

[0100] Such as figure 2 As shown, preferably, the blanking part 112 includes: a blanking rod 1121 above the base 13, a low-material detection device 1122 arranged on the blanking rod 1121, and a limiter arranged in a straight line with the blanking rod 1121 under the base 13 A piece 1123 and a servo spiral cutter 1124 arranged adjacent to the limit piece 1123 ; w...

Embodiment 3

[0117] refer to figure 1 , Figure 11 and Figure 12 The difference from the above embodiment is that the filling device 2 includes: a beverage raw material feeding assembly 23, a lower hopper 22 arranged below the beverage raw material feeding assembly 23, a beverage powder filling head 21 arranged below the lower hopper 22 ;

[0118] The beverage powder filling head 21 includes a powder feeding tube and a screw; the powder feeding tube is in the shape of a funnel, and one end of the expanding tube is connected to the feed pipe 2102, and the other end is a straight tube-shaped outlet extending vertically downward. Feeding pipe 2101, when feeding, the outlet of the outlet pipe presses the top of the feeding cup. The screw includes a rotatable shaft 2104 and a helical blade 2105 arranged around the shaft. The shaft 2104 is connected to a servo motor 2103 and rotates under the drive of the servo motor 2103 . The screw rod extends at the center of the powder feeding pipe, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com