Anti-electrostatic method of chip device

An anti-static, chip technology, applied in the direction of static electricity, non-printed electrical components connected to the printed circuit, electrical components, etc., can solve the problem of adding a shielding cover as a whole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

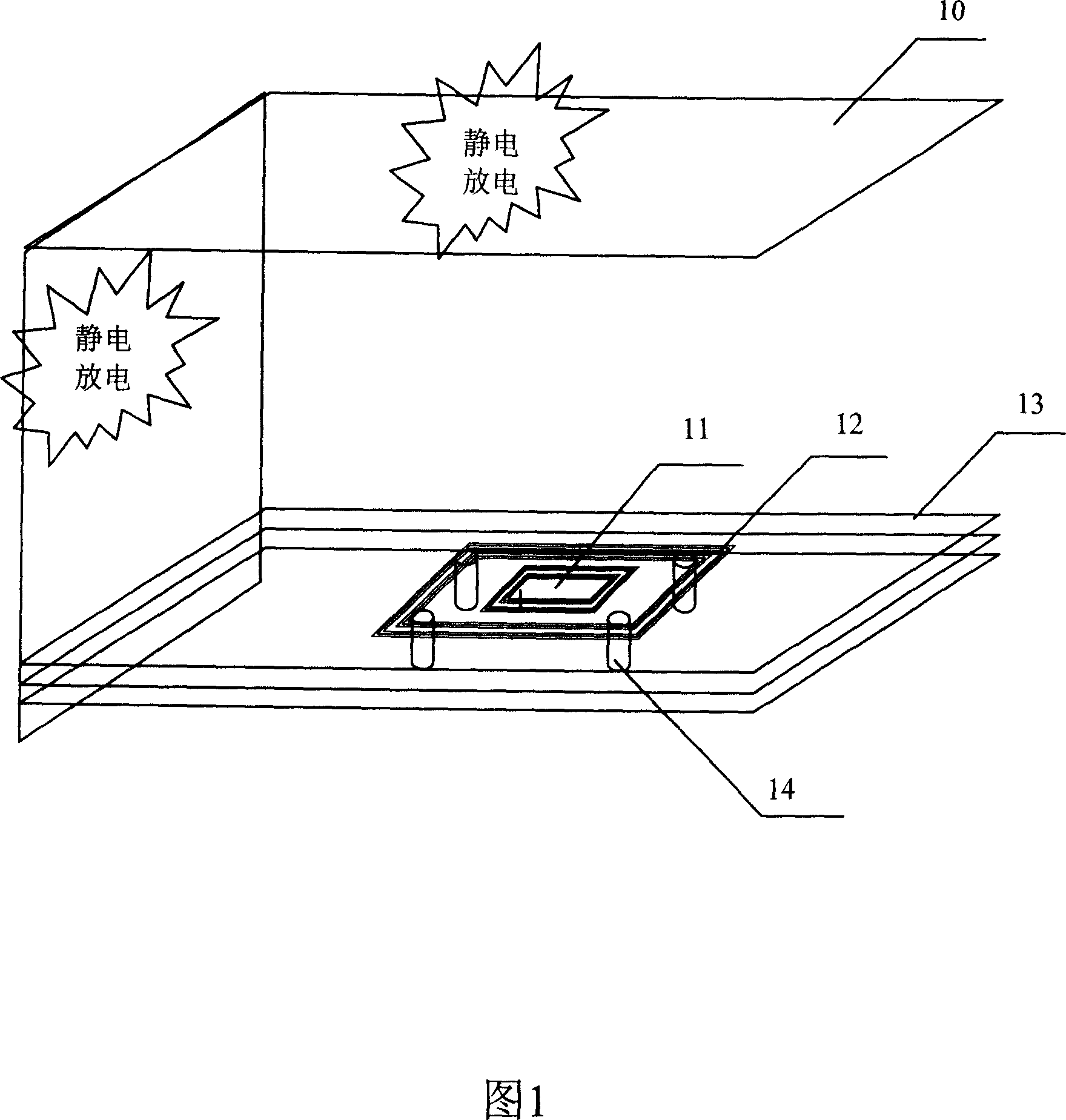

[0019] In order to make the present invention easier to understand, this embodiment is implemented based on the following ideas.

[0020] Static electricity is the static charge on the surface of an object. Static electricity is a kind of electrical energy, which remains on the surface of an object. It is the result of the local imbalance of positive and negative charges, which is formed by the transfer of electrons or ions.

[0021] Electrostatic discharge is the transfer of charge that occurs when objects with different electrostatic potentials approach or pass through direct contact.

[0022] Shielding is made of conductive or magnetically conductive materials such as shells, plates, sleeves, tubes and other shapes to encapsulate the object to be protected, so as to prevent the interference of surrounding electromagnetic energy or prevent unnecessary electromagnetic energy from coupling to other sensitive equipment.

[0023] The protection ground is the loop ground of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com