Centrifugal clutch

A centrifugal clutch and clutch plate technology, applied in clutches, automatic clutches, mechanical equipment, etc., can solve the problems of complex mechanism, difficult adjustment, increased cost, etc., and achieve the effect of firm fixed state, durability and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

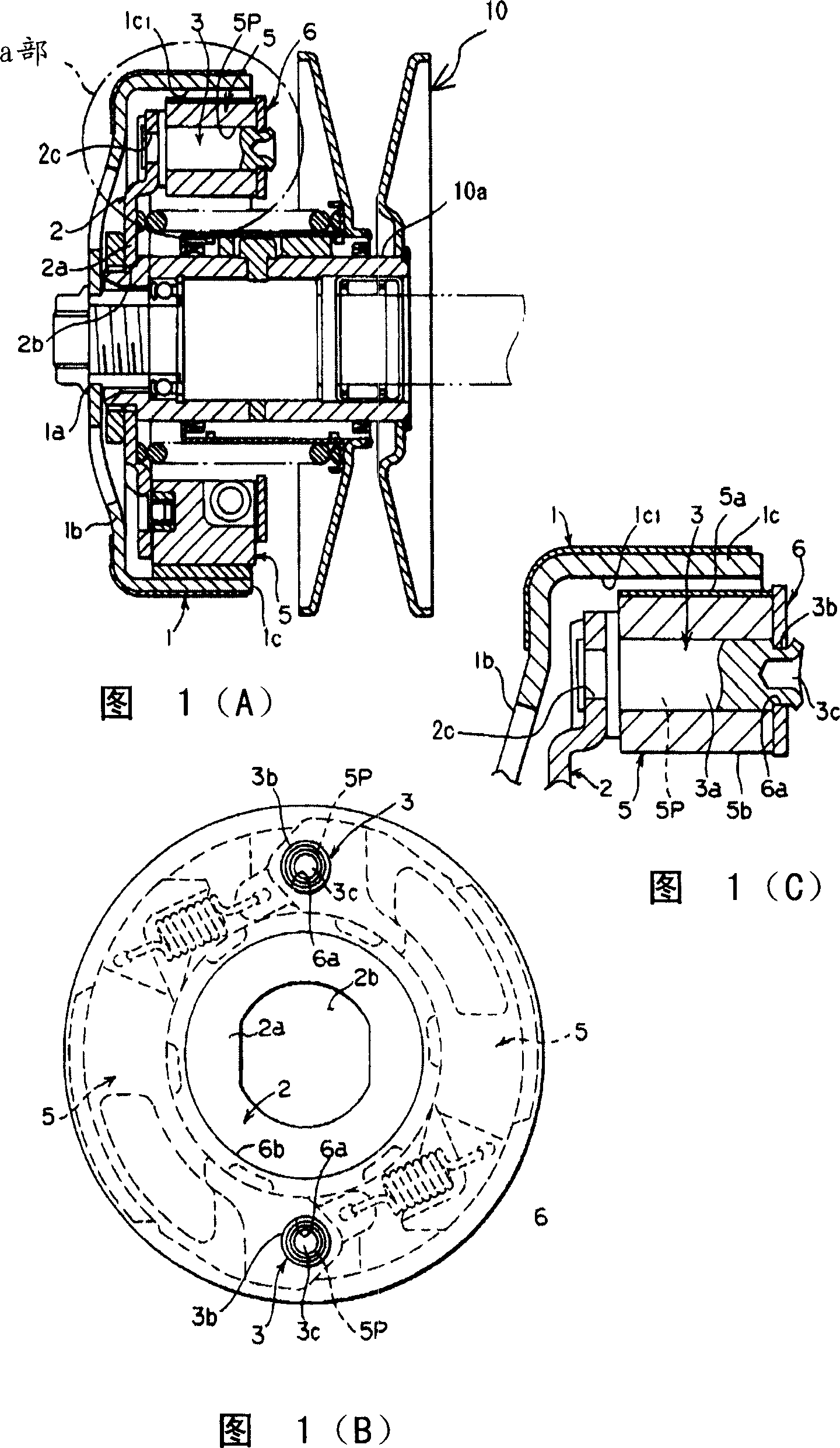

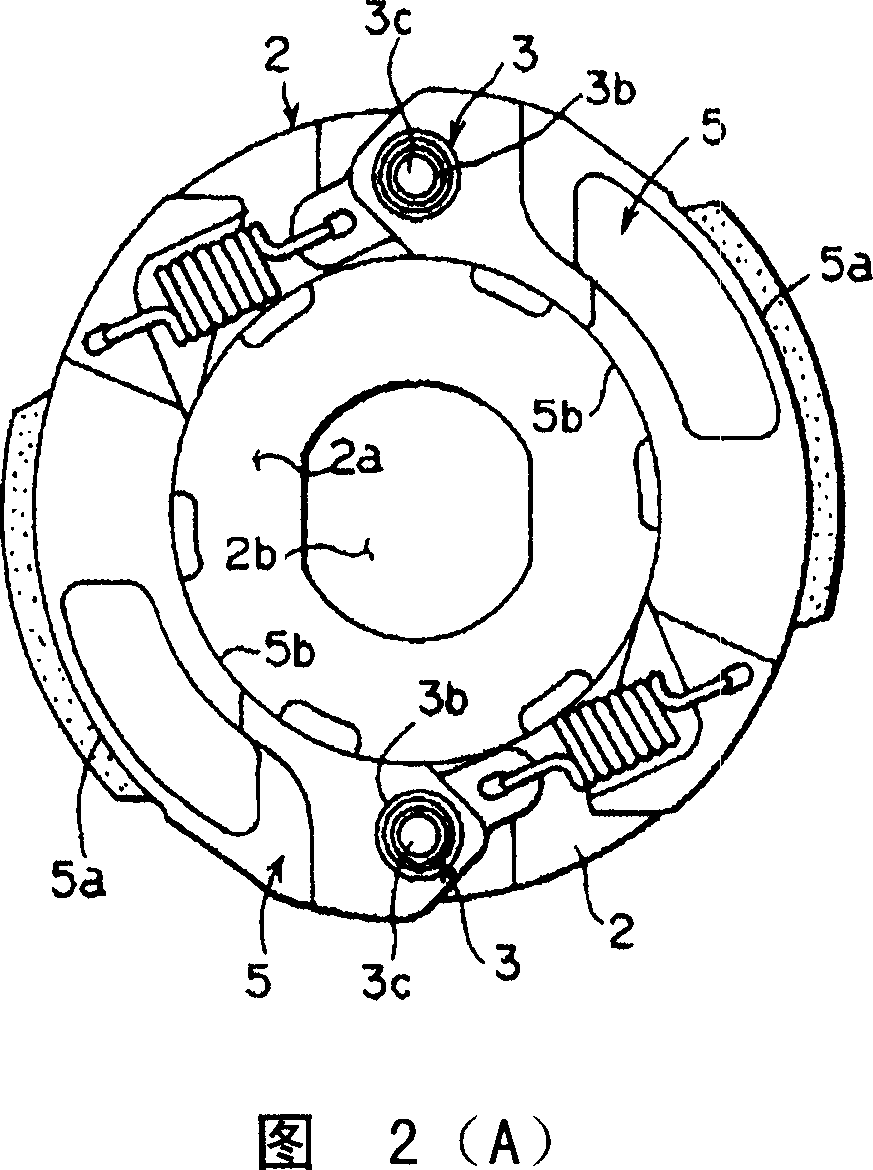

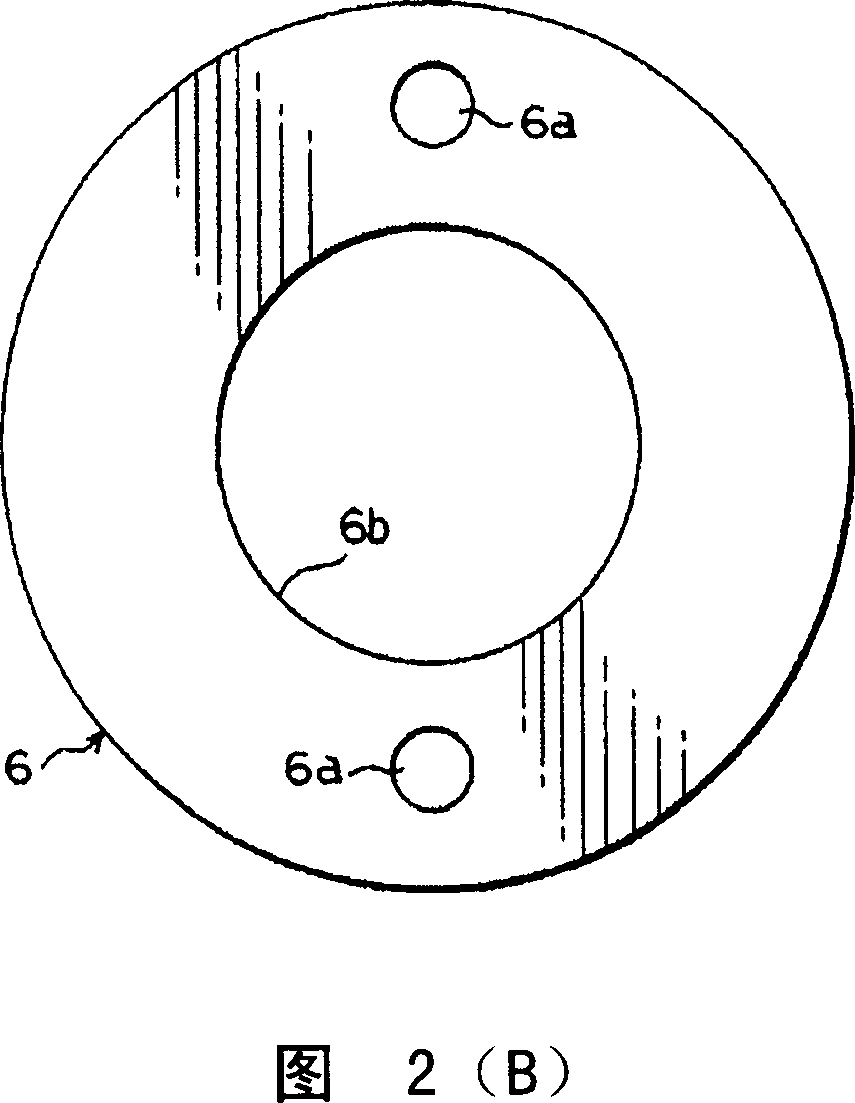

[0024] Embodiments of the present invention will be described below based on the drawings. Fig. 1 is an enlarged cross-sectional view of a centrifugal clutch connected to a continuously variable transmission of the present invention and its main parts. The centrifugal clutch of the present invention, as shown in Figure 1(A), is used together with continuously variable transmissions that share the same shaft mechanism and are adjacently arranged to disconnect / disconnect the driving force transmitted through the continuously variable transmission in vehicles such as motorcycles and the like. connected function. The centrifugal clutch is mainly composed of a clutch housing 1, a clutch plate 2, a centrifugal hammer 5 and the like. A device connected to this centrifugal clutch is a driven-side speed change pulley 10 (see FIG. 1(A)), which is of a variable pulley groove width. The driven side speed change pulley 10 is rotated by a driving side speed change pulley (not shown) via a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com