Front panel migrating apparatus

A transfer device and carrier device technology, which is applied in the directions of identification device, transportation and packaging, conveyor objects, etc., can solve the problems of lower yield rate of panels and uneven brightness of panel surface, so as to increase production capacity and save replacement of transfer devices. Cost, effect of widespread use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

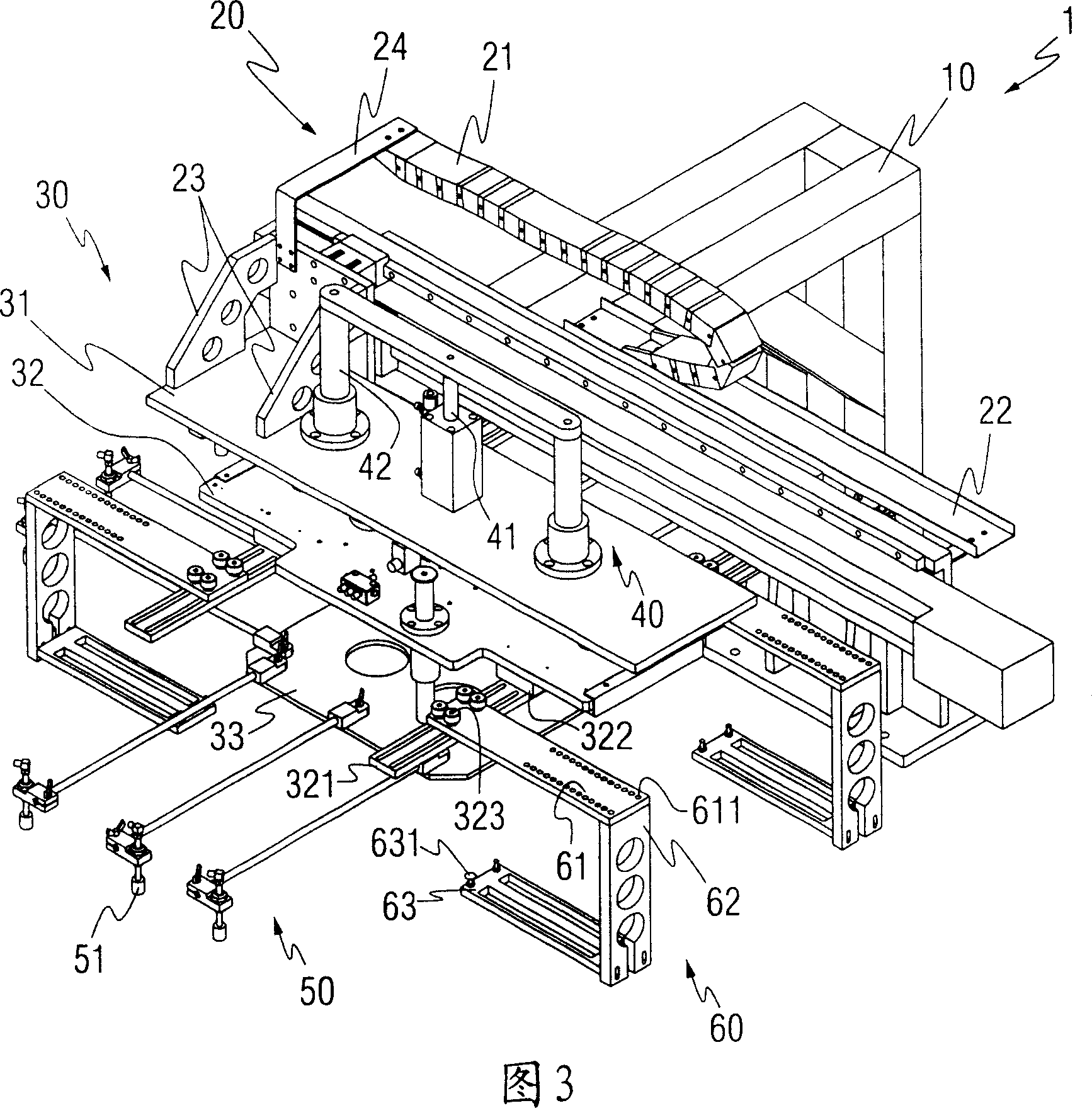

[0045] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the panel transfer device proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , as detailed below.

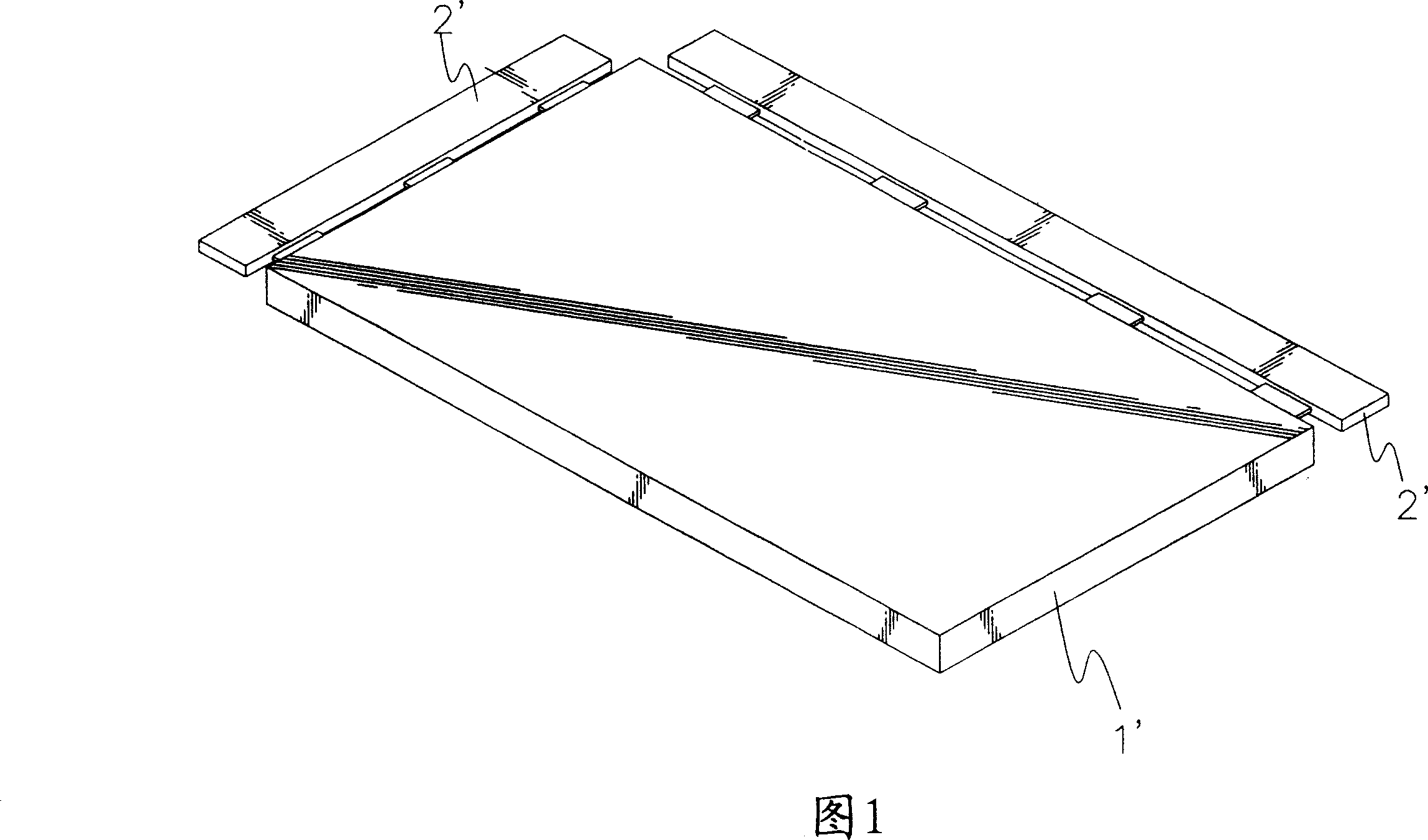

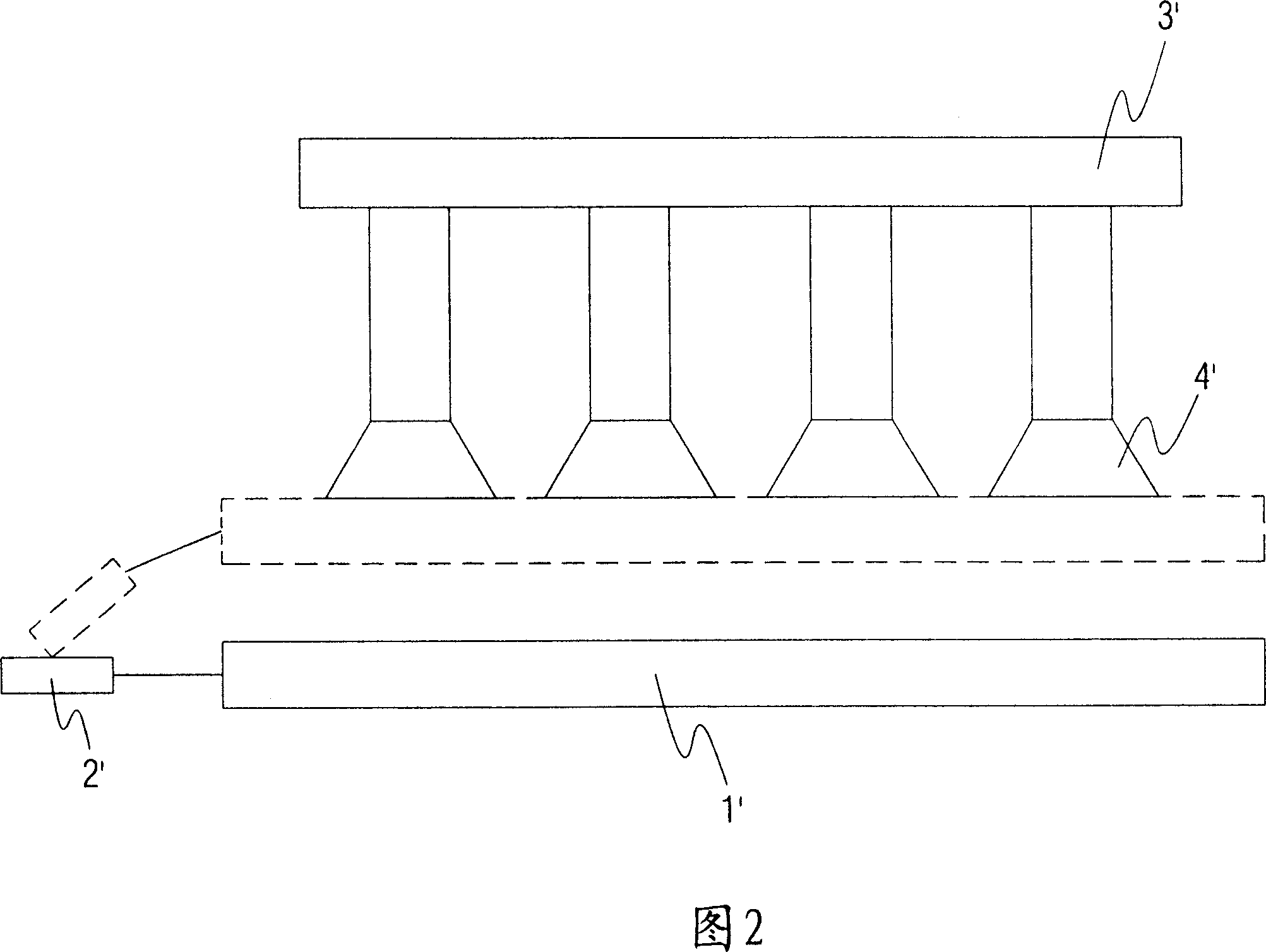

[0046] First, please refer to FIG. 3 , which is a perspective view of a panel transfer device of the present invention. A panel transfer device 1 according to a preferred embodiment of the present invention includes a machine base 10 and a carrying device, the machine base 10 includes a transmission mechanism 20, the carrying device is arranged on the transmission mechanism 20, and the carrying device further includes A load base 30 , a lifting system 40 , a plurality of suction cup sets 50 , a plurality of transfer arms 60 and a clamping pneumatic cylinder 70 .

[0047] Please re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com