Method for operating an injection moulding machine

An injection molding machine, movement technology, applied in the field of triggering mold safety devices, to achieve the effect of avoiding mold damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

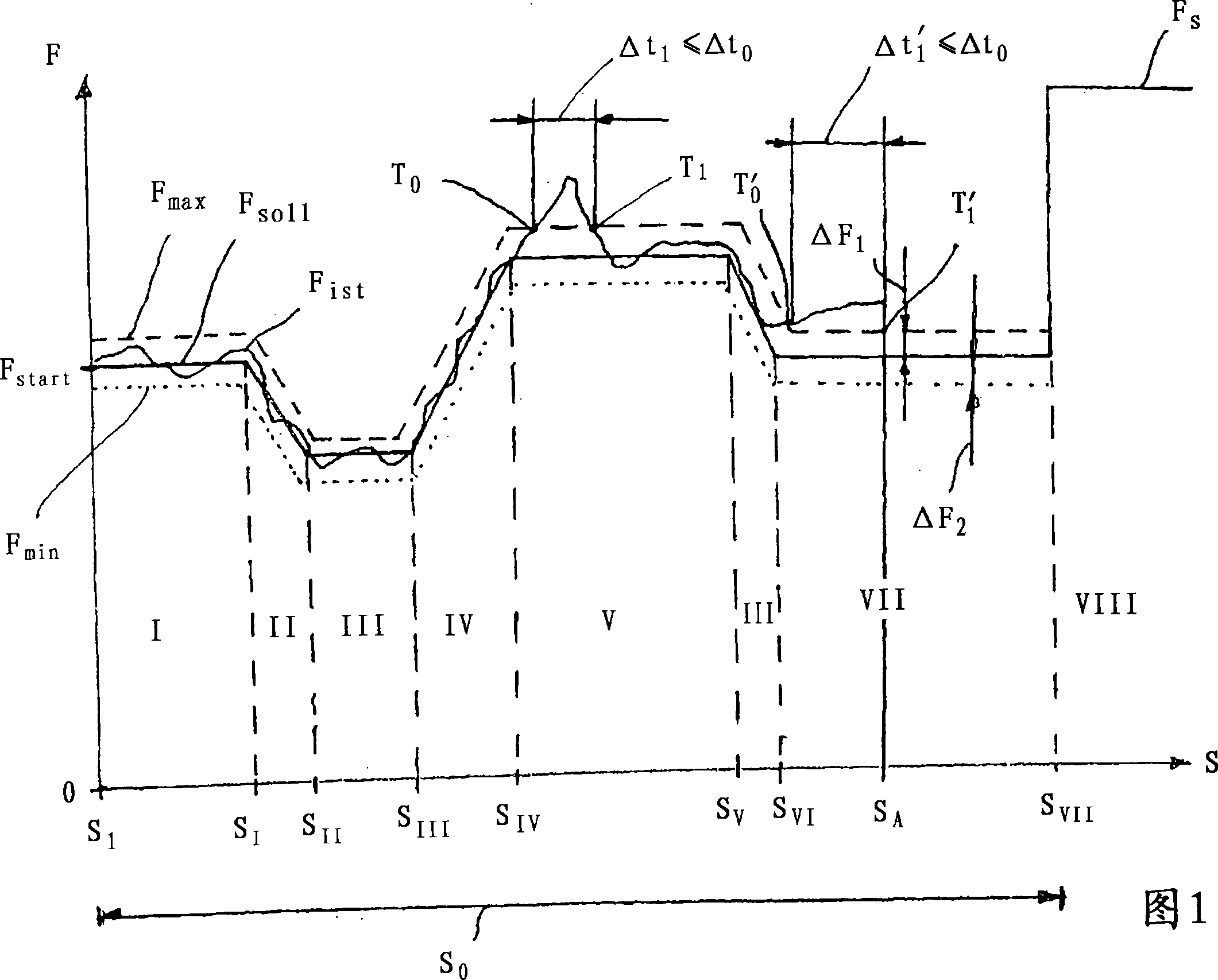

[0013] Figure 1 schematically shows the closing stroke S along the mold halves 0 force curve. Close stroke S 0 For example, it is divided into regions I to VII according to FIG. 1 . For example, a solid line consisting of straight line segments indicates the rated closing force F soll or the rated closing force along the closing stroke S 0 extension direction.

[0014] Especially with respect to the rated force F soll The dotted line offset parallel to the solid line indicates the maximum permissible closing force F max . Maximum allowable force F max The extension of the dotted line goes towards the rated closing force F soll The line of is deviated upward by an amount ΔF. Use S for the stroke point at the end of each zone I-VII I ~S VII express.

[0015] In zone I, rated closing force F soll For example with value F start . Nominal closing force F in zone II soll eg linearly down to a lower value. In zone III, rated closing force F soll Constantly held at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com