Device for connection of a linear motor armature to a linear track

A technology of guiding mechanism and linear motor, which is applied in the direction of electromechanical devices, linear motion bearings, mechanical equipment, etc., can solve the problems of unpopular linear guiding mechanism and increase the quality of installation space, so as to prevent premature wear and prevent gradual worsening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

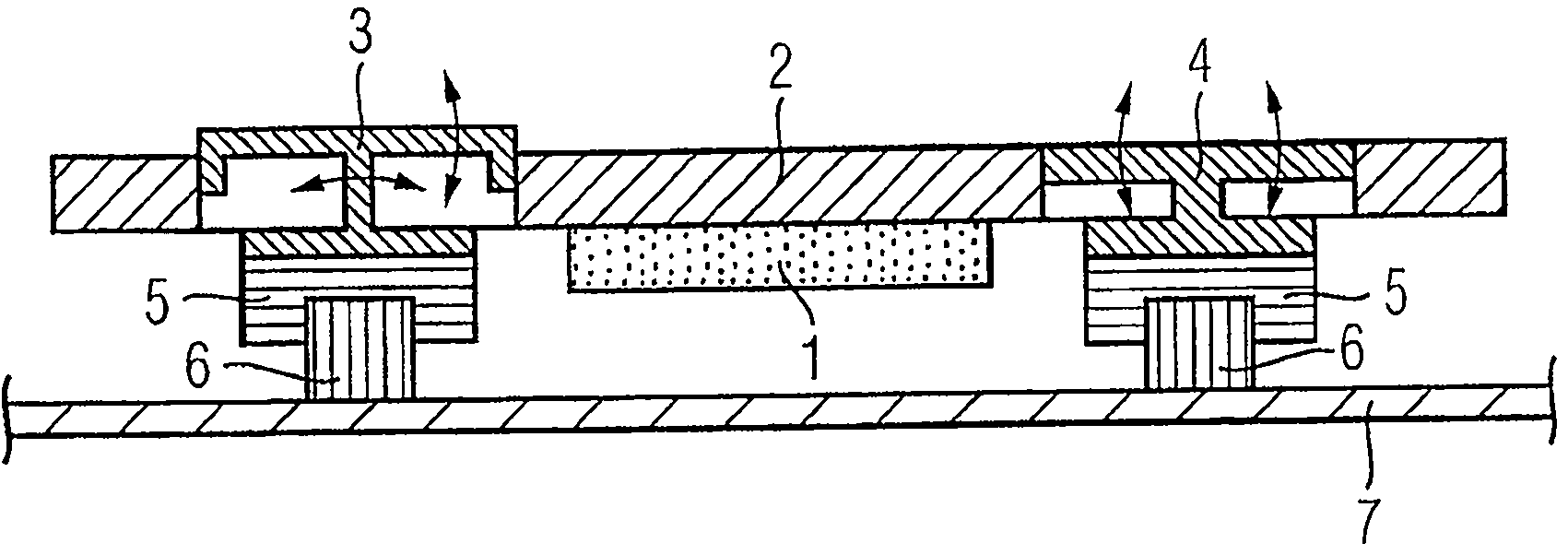

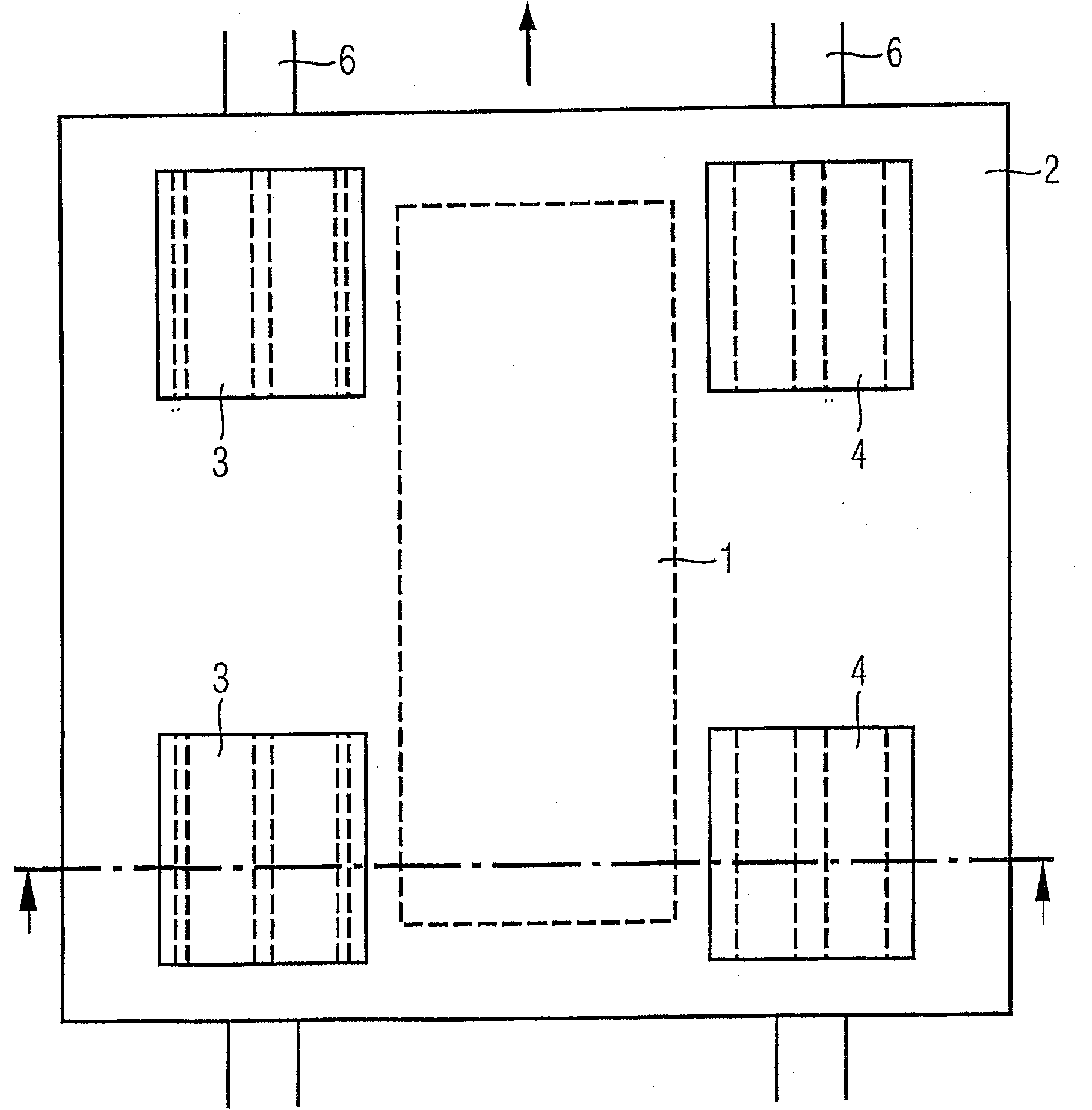

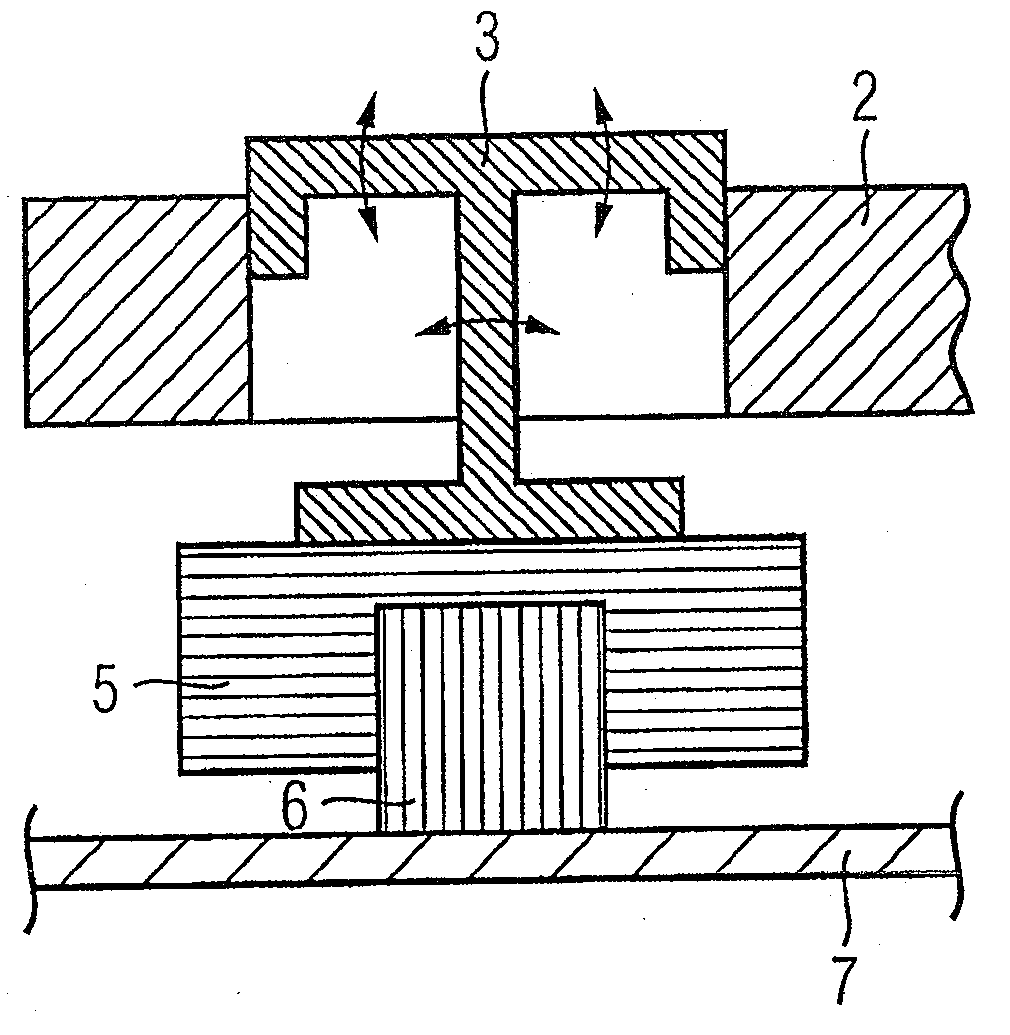

[0031] exist figure 1 and 2 A first preferred embodiment of the device according to the invention is shown in . The linear motor rotor (1) is fixed on the bottom surface of a movable mounting part (2), here a rectangular support plate (2). A support arm or a mounting head is also conceivable as the movable mounting part ( 2 ), for example. The support plate (2) passes through the first type of the first type of balancing member (3) and the first type of the second type of balancing member (4) and the fourth guide member (5) at its corner Or guide dolly (5) connects. The guide trolley (5) is functionally fitted with a parallel track (6) of a linear guide mechanism, so that the figure 2 Move in the direction of movement indicated by the arrow. The track (6) is fixed on a track base (7) which consists of a metal plate. The linear guide mechanism consists of a track (6) and a track base (7). The linear motor rotor (1) is located at a small distance from a linear motor stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com