Penile Pump with Side Release Mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

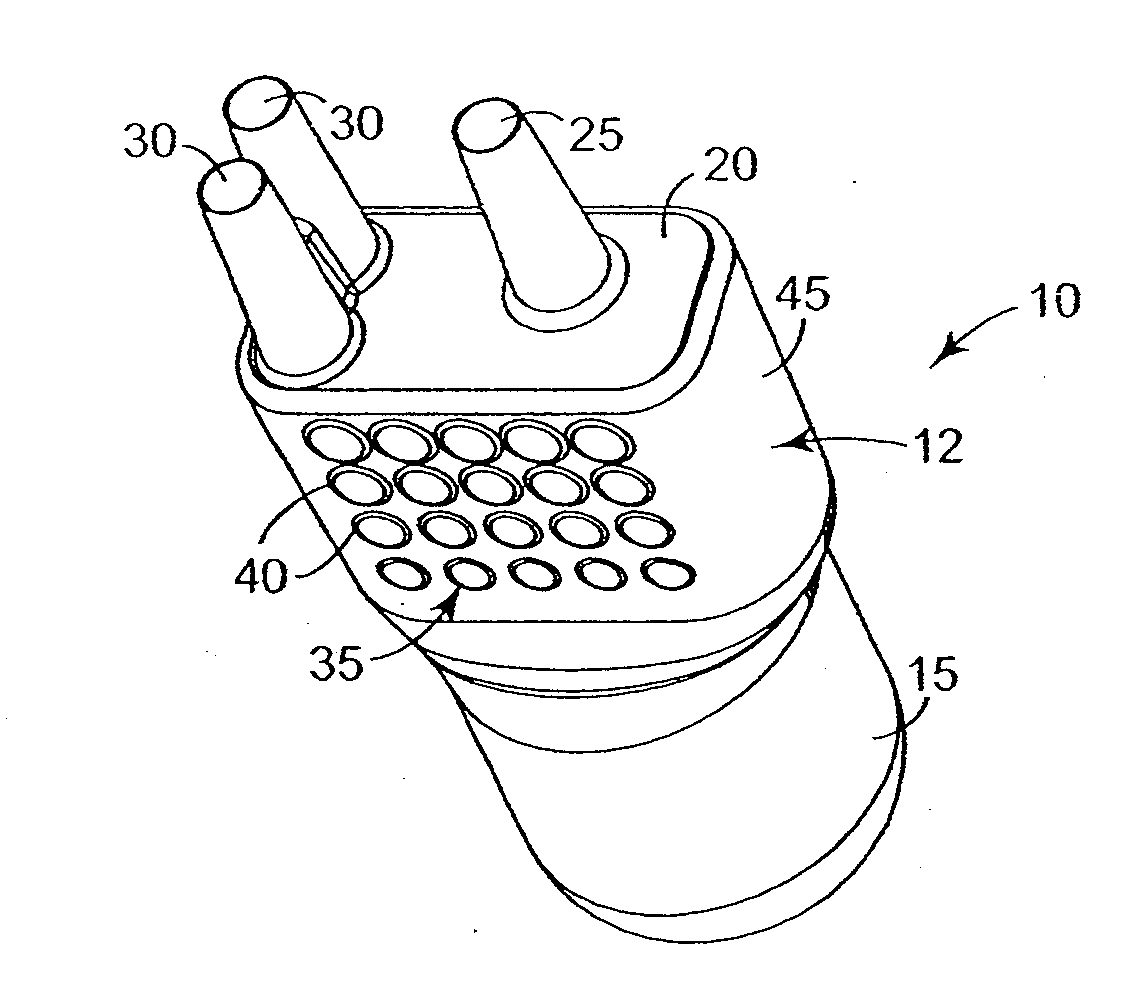

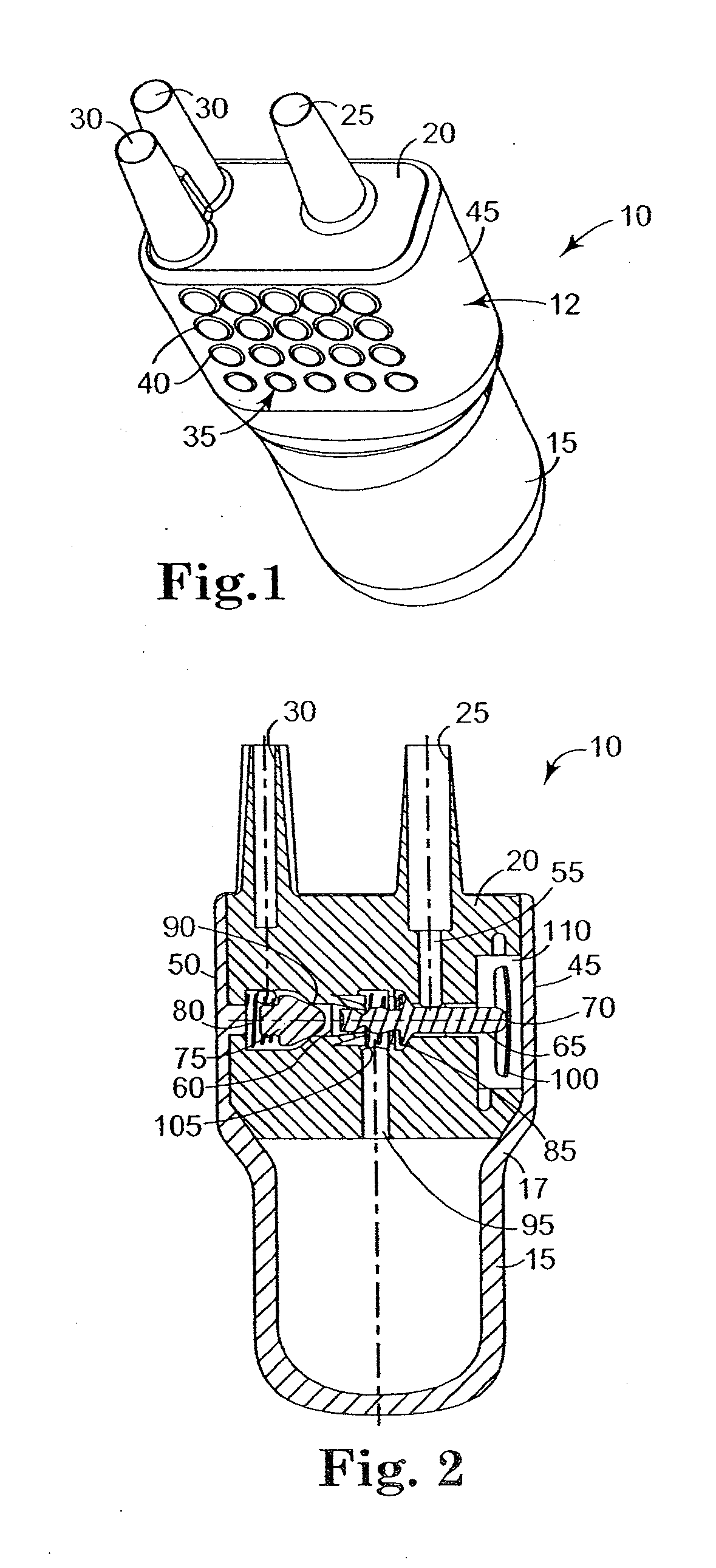

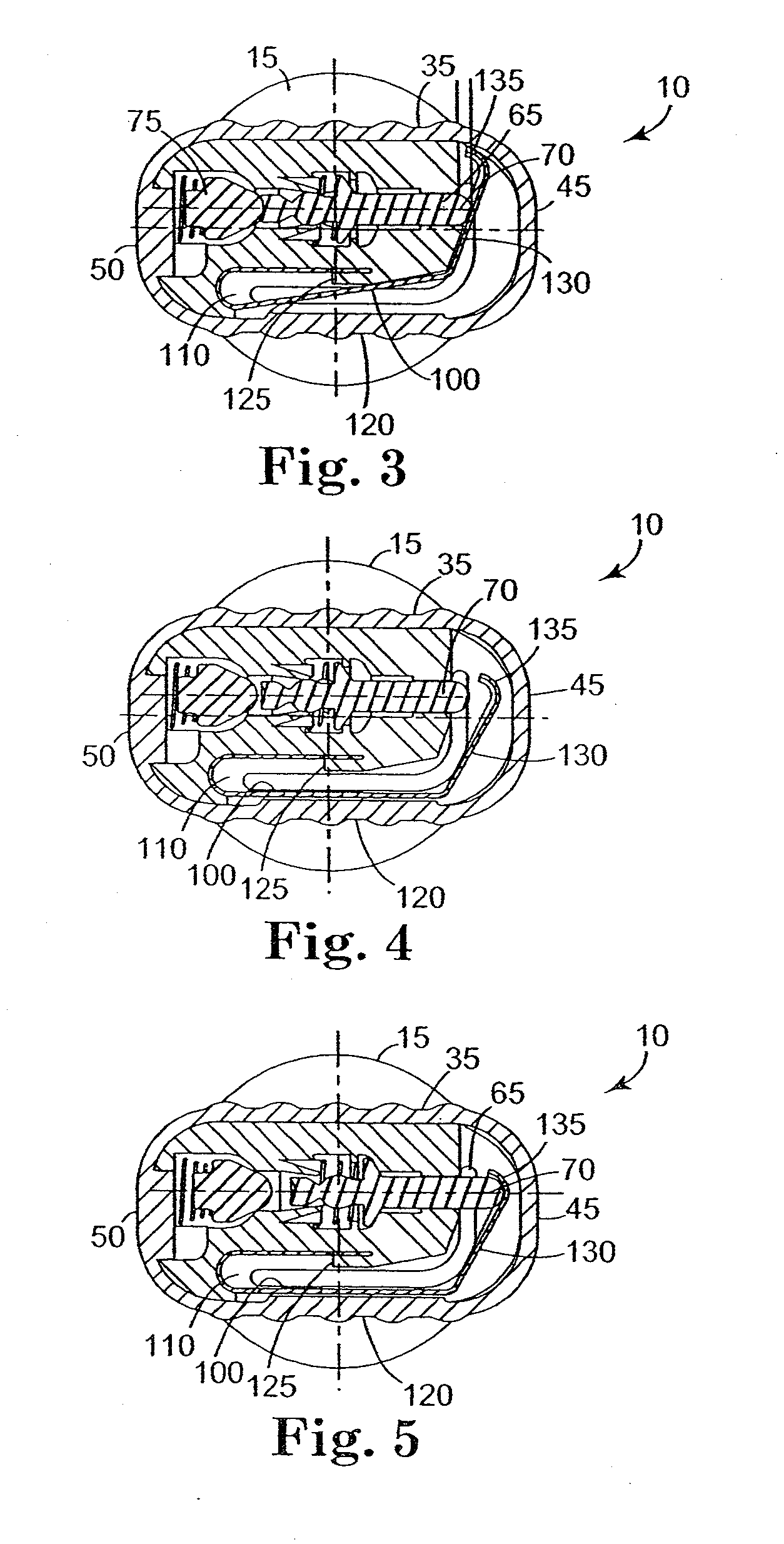

[0037]Referring to FIG. 1, a pump and valve assembly is illustrated and generally referred to as 10. Pump and valve assembly 10 includes two different sections: valve housing 12 and pump bulb 15. Pump bulb 15 is a compressible member, defining a chamber more clearly shown in FIG. 2. Valve housing 12 is fluidly coupled to pump bulb 15 and contains the various other working components of pump and valve assembly 10. Pump and valve assembly 10 will be fluidly coupled to a reservoir and a pair of cylinders (not shown). This is accomplished through tubing connected to reservoir coupling 25 and cylinder couplings 30, which are integral with valve housing 12. Pump and valve assembly 10 is configured such that pump bulb 15 extends from one end of valve housing 12, while reservoir coupling 25 and cylinder couplings 30 extend from the other. Thus, when implanted in the patient, reservoir coupling 25 and cylinder couplings 30, and the fluid tubing they are coupled to, are oriented toward the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com