Hook assembly used for waist-adjusing mechanism of garment and garment having waist-adjusting mechanism

a technology of adjusting mechanism and hook assembly, which is applied in the direction of hook fasteners, clothes making applications, protective garments, etc., can solve the problems of inability to adjust the waist size of pants or skirts, and inability to meet the needs of women's waist size adjustment,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0177] SECOND EMBODIMENT

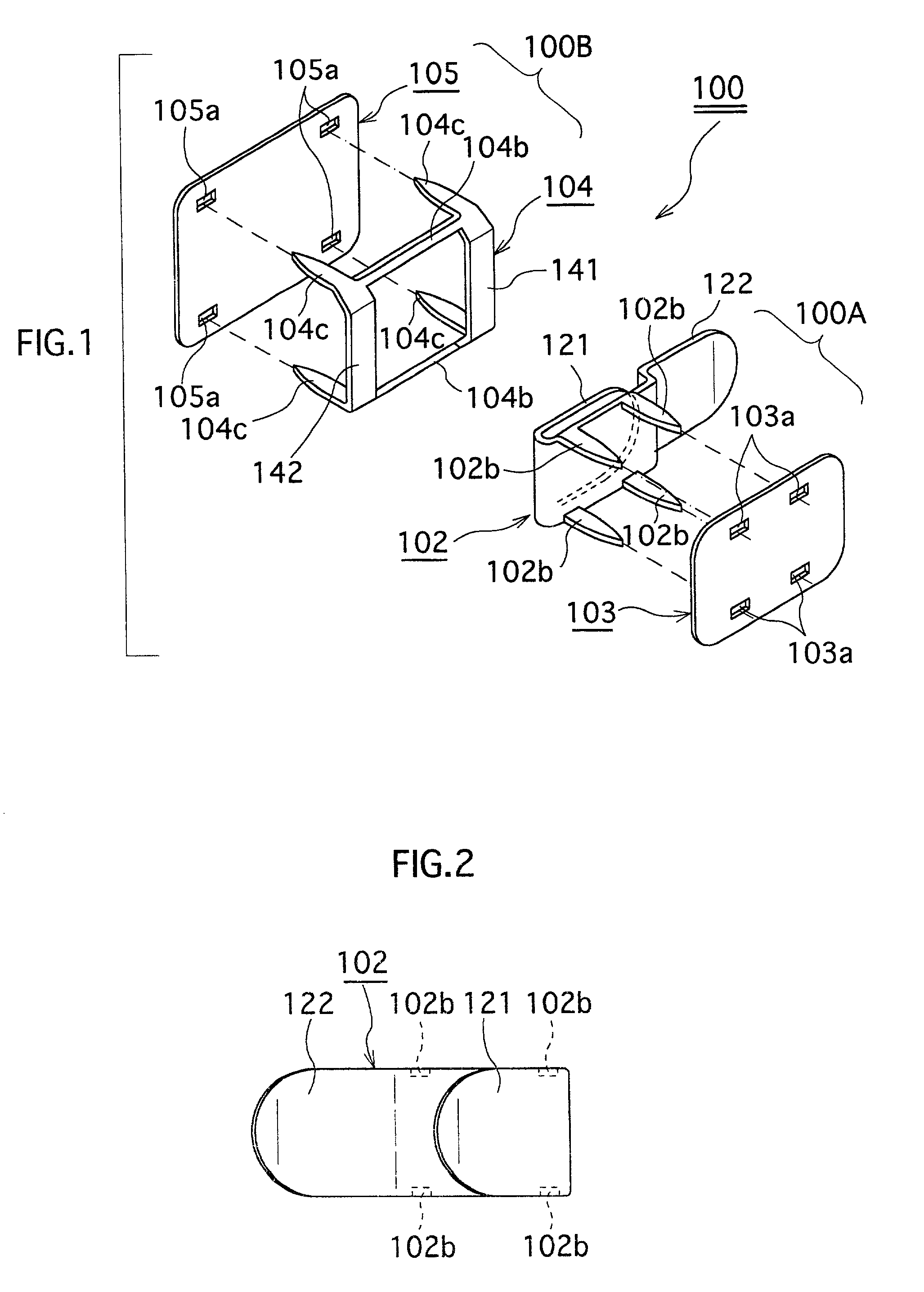

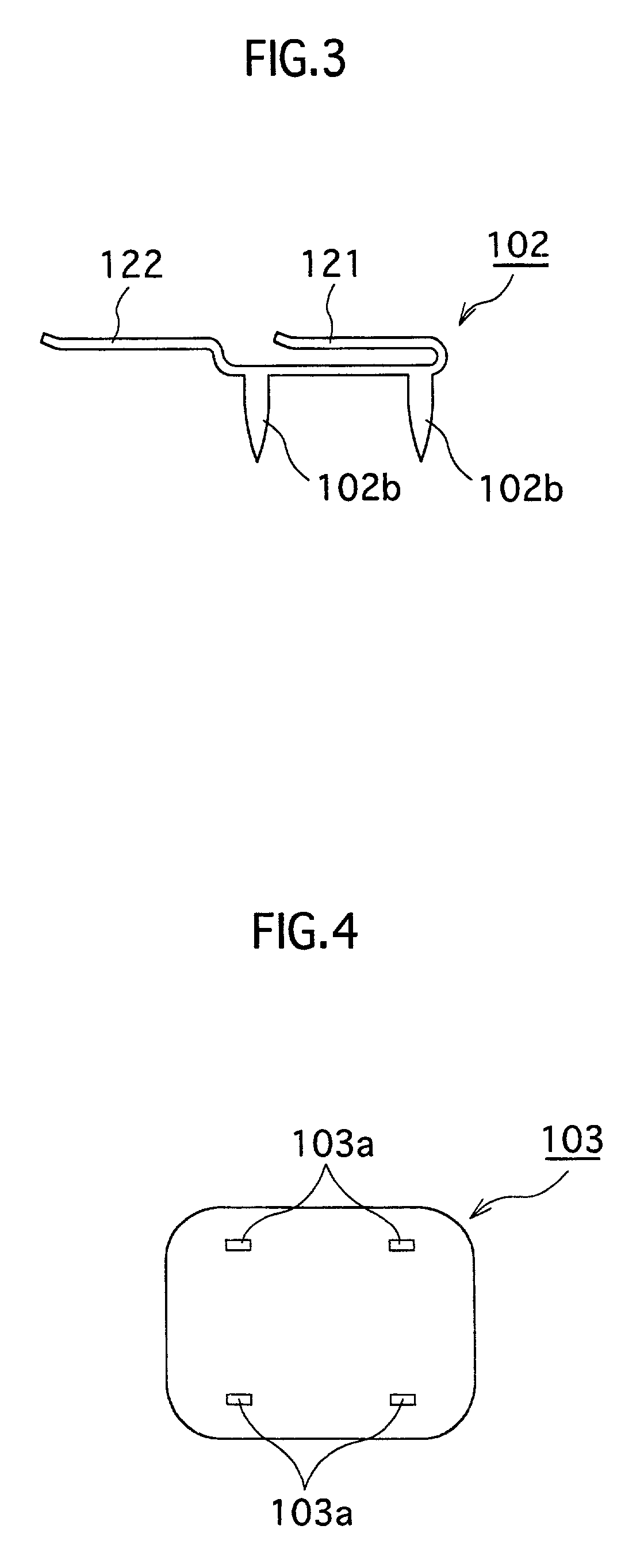

[0178] A second embodiment is describer hereafter. FIG. 15 is an exploded perspective view of a hook assembly according to a second embodiment of the invention.

[0179] In a hook assembly 100 according to the second embodiment, a hook attachment plate 103X of a hook element 100X has accommodating dents 103b at a jointed portion with the hook body 102 so as to accommodate the hook claws 102b, in contrast with the hook assembly of the first embodiment. Moreover, a socket attachment plate 105X of a socket element 100BX has accommodating dents 105b at a jointed portion with the socket body 104 so as to accommodate the socket claws 104c. The hook attachment plate 103X has through holes 103ax corresponding to the through holes 103a. Furthermore, the socket attachment plate 105X has through holes 105ax corresponding to the through holes 105a.

[0180] In addition, the socket attachment plate 105X has a bulged portion 105c configured by an X-shaped groove between those tw...

third embodiment

[0183] THIRD EMBODIMENT

[0184] A third embodiment is describer hereafter. FIG. 16 is an exploded perspective view of socket element 100BY of a hook assembly 100 according to a third embodiment of the invention.

[0185] In the third embodiment, a socket attachment plate 105Y of a socket element 100BY has accommodating dents 105by at a jointed portion with the socket body 104 so as to accommodate the socket claws 104c.

[0186] At the jointed portion of the socket attachment plate 105Y with the socket body 104, the accommodating dents 105by are provided only at an area where the socket claws 104c are housed. Thus, there is provided a room where connecting bridges 104b of the socket body 104 are fitted without interruption. The socket attachment plate 105Y has through holes 105ay corresponding to the through holes 105a.

[0187] In addition, the socket attachment plate 105Y has a bulged portion 105c configured by an X-shaped groove between those two accommodating dents 105b.

[0188] The hook asse...

fifth embodiment

[0194] FIFTH EMBODIMENT

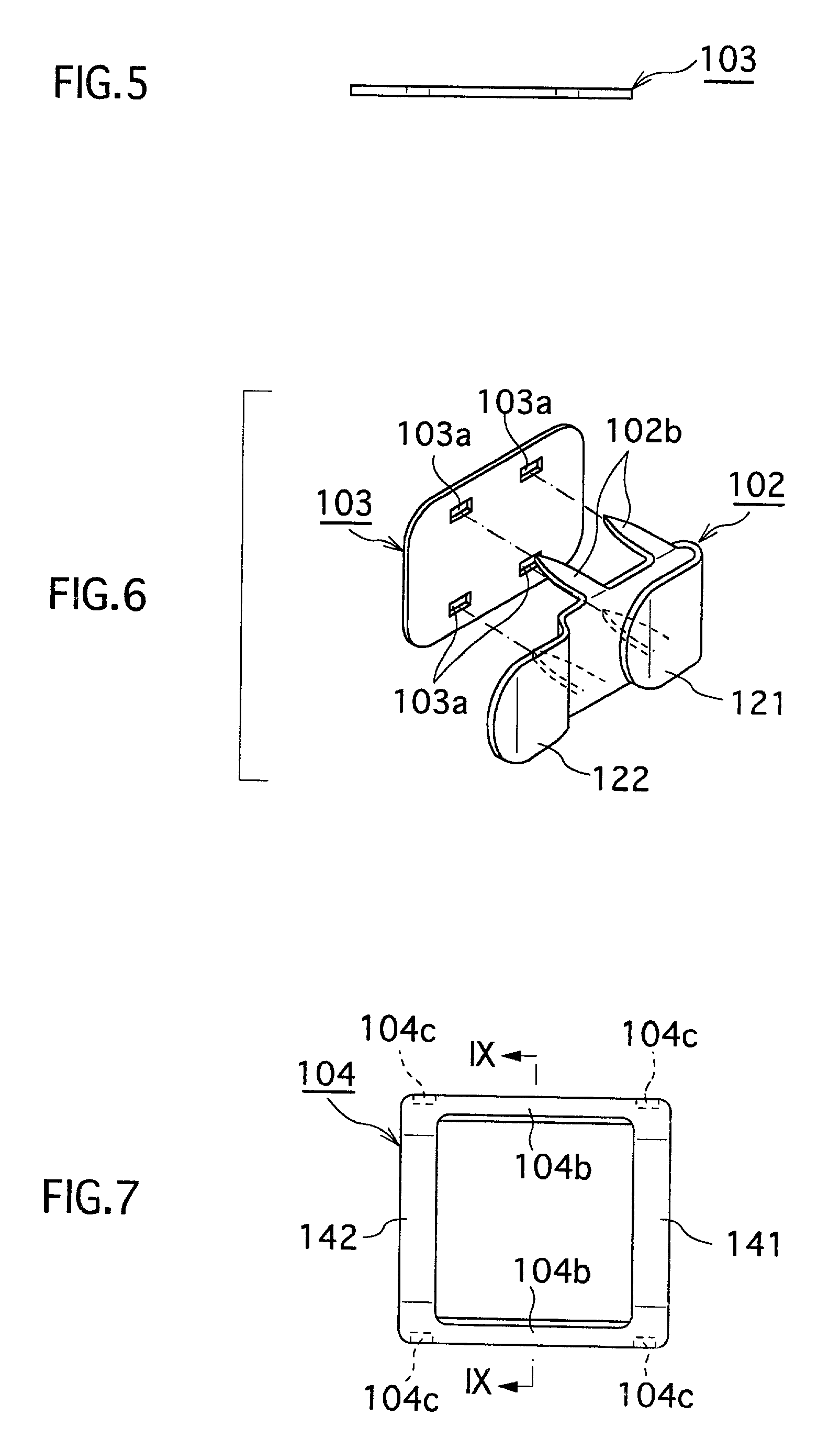

[0195] A fifth embodiment is describer hereafter. FIG. 18 is an exploded perspective view of a hook assembly according to a fifth embodiment of the invention.

[0196] The fifth embodiment of hook assembly 100 can be structured to have the conventional hook element 200A and the first embodiment of socket element 100B. Specifically, the socket element 100B has the plural sockets 141, 142 formed at a fixed interval in the hooking direction so as to be caught by the hook 221 of the hook body 202.

[0197] With such structure, the hook element 200A can be easily assembled by inserting the bendable hook claws 202b in the through holes 203a of the hook attachment plate 203 and bending them thereafter. Similarly, the socket element 100B can be easily assembled by inserting the bendable socket claws 104b in the through holes 105a of the socket attachment plate 105 and bending them thereafter. Then, the hook element 200A is attached to one of the parted portions of the waist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com